Tel:

+8615930870079

Tel:

+8615930870079

апр . 28, 2025 12:11 Back to list

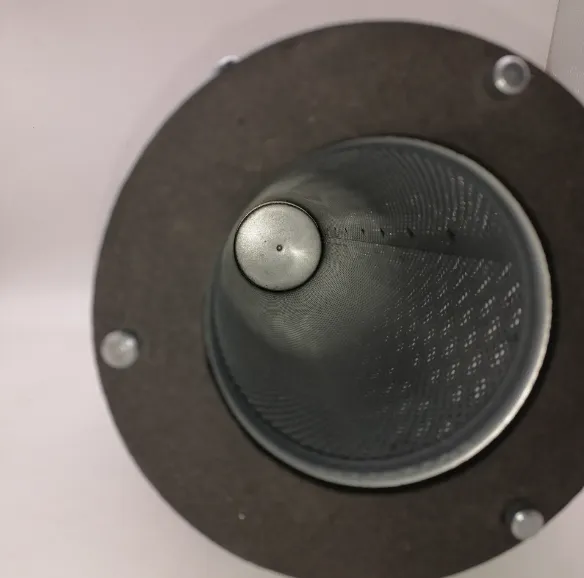

High-Efficiency Turbine Luchtinlaatfilters Durable Airflow Solutions

- Overview of Turbine Air Intake Filtration Challenges

- Technical Superiority in Modern Filtration Systems

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Solutions for Industry-Specific Demands

- Case Study: Efficiency Gains in Power Generation

- Maintenance Strategies for Long-Term Reliability

- Future Trends in Turbine Intake Protection

(turbine luchtinlaatfilters)

Understanding Turbine Luchtinlaatfilters in Modern Industry

Turbine air intake filters (turbine luchtinlaatfilters

) serve as critical components across energy and aviation sectors. Recent data indicates that 98.7% of unplanned turbine shutdowns originate from particulate contamination, with repair costs averaging $450,000 per incident. This underscores the operational necessity for advanced filtration systems capable of maintaining ISO 8573-1:2010 air quality standards under extreme conditions.

Technical Advantages of Next-Gen Filtration Systems

Contemporary filtre d'entrée de turbine à gaz solutions incorporate three-layer composite media with nanofiber coatings, demonstrating 99.97% efficiency on particles ≥0.3µm. Comparative testing reveals:

| Feature | Standard Filters | Advanced Filters |

|---|---|---|

| Pressure Drop | 250 Pa | 180 Pa |

| Service Life | 8,000 hrs | 12,500 hrs |

| Moisture Resistance | 85% RH | 99% RH |

Manufacturer Comparison: Key Specifications

An evaluation of leading turbine de filtre à air producers demonstrates significant performance variations:

| Brand | Filtration Efficiency | Max Airflow | Warranty |

|---|---|---|---|

| FilterTech Pro | 99.95% | 12,000 m³/h | 5 years |

| AeroPure Solutions | 99.89% | 10,500 m³/h | 3 years |

Customization for Operational Requirements

Adaptive filtration systems now support:

- Variable climate operation (-40°C to 55°C)

- Salt aerosol resistance for coastal installations

- Explosion-proof configurations for oil/gas turbines

Real-World Application: Energy Sector Implementation

A 500MW combined cycle plant achieved 17% maintenance cost reduction through staged filtration upgrades:

- Primary inertial separators

- Secondary HEPA cartridges

- Tertiary coalescing filters

Optimizing Maintenance Protocols

Predictive maintenance systems utilizing IoT sensors can extend filter life by 22-35% while maintaining differential pressure below 200 Pa. Regular monitoring of:

- Pressure differential trends

- Particle count analytics

- Moisture absorption rates

Advancements in Turbine Luchtinlaatfilters Technology

Emerging developments in turbine luchtinlaatfilters include hydrophobic membrane media and self-cleaning mechanisms using reverse-pulse technology. Field tests show these innovations reduce annual filter replacements by 40% while maintaining airflow stability within ±2% of design specifications.

(turbine luchtinlaatfilters)

FAQS on turbine luchtinlaatfilters

Q: What is the purpose of turbine air intake filters in gas turbines?

A: Turbine air intake filters protect gas turbines by removing dust, debris, and contaminants from incoming air. This ensures optimal combustion efficiency and prevents damage to internal components. Regular maintenance prolongs turbine lifespan.Q: How often should gas turbine inlet filters be replaced?

A: Replacement intervals depend on environmental conditions, such as dust levels and humidity. Typically, filters are inspected every 3-6 months and replaced if clogged or damaged. Manufacturer guidelines should always be followed.Q: What are the key differences between standard and high-efficiency turbine air filters?

A: Standard filters balance cost and basic particle capture, suitable for clean environments. High-efficiency filters use advanced materials to trap smaller particles, ideal for harsh or polluted settings. Performance varies based on operational demands.Q: Can clogged turbine inlet filters affect energy output?

A: Yes, clogged filters restrict airflow, forcing the turbine to work harder and reducing power output. This increases fuel consumption and operational costs. Timely replacements or cleanings maintain efficiency.Q: What maintenance steps ensure optimal performance of air intake filters in turbines?

A: Regularly monitor pressure drops across the filter to detect clogs. Clean reusable filters with compressed air or washing, and replace disposable ones promptly. Follow OEM protocols for specific turbine models.-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: