Tel:

+8615930870079

Tel:

+8615930870079

нов . 08, 2024 18:24 Back to list

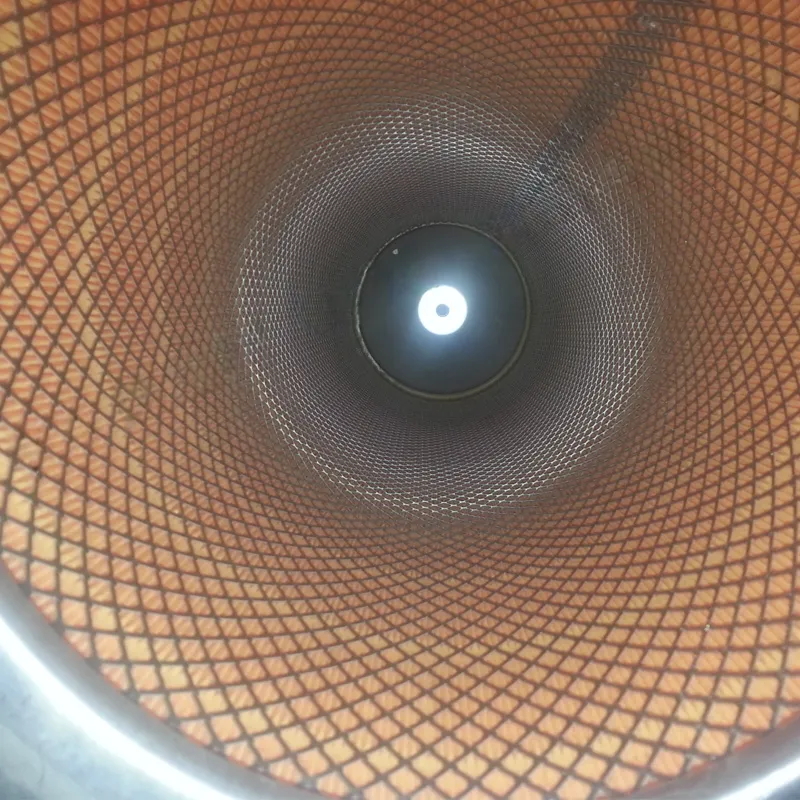

ss sintered filter cartridge

Understanding SS Sintered Filter Cartridges

Sintered filter cartridges have emerged as a vital component in various filtration processes, particularly in industries that demand high efficiency and reliability. Among the different types of filter cartridges available, stainless steel (SS) sintered filter cartridges offer superior performance and durability, making them ideal for a wide range of applications.

What are SS Sintered Filter Cartridges?

SS sintered filter cartridges are designed using a process called sintering, where stainless steel powder is compacted and heated until it forms a solid, porous structure. This unique manufacturing process results in a filter that possesses excellent mechanical strength, corrosion resistance, and high filtration efficiency. The porosity of these cartridges enables effective filtration while allowing for easy cleaning and regeneration.

Advantages of SS Sintered Filter Cartridges

1. Durability One of the primary benefits of stainless steel sintered filters is their durability. Unlike their polymer counterparts, these filters can withstand extreme temperatures and harsh chemical environments. This makes them suitable for applications in pharmaceuticals, food and beverage, petrochemicals, and other industries where robust filtration is necessary.

2. High Filtration Efficiency SS sintered filters feature a uniform pore structure, allowing them to capture particles of various sizes effectively. The effectiveness of these filters can be further enhanced by selecting the appropriate pore size for specific applications, ensuring that even the smallest contaminants are removed from liquids and gases.

3. Reusability and Cleanability Unlike disposable filters, SS sintered filter cartridges are reusable and can be cleaned, which significantly reduces operational costs. Various cleaning methods, including backwashing and ultrasonic cleaning, can prolong the life of these filters while maintaining their filtration efficiency.

4. Wide Temperature and Pressure Range These cartridges can operate under extreme temperature and pressure conditions, making them suitable for demanding processes where other materials might fail. This feature is particularly beneficial in industries dealing with high-pressure liquids or gases.

ss sintered filter cartridge

5. Customization Manufacturers of sintered filter cartridges can customize the size, shape, and pore structure based on the specific needs of the application. This level of customization ensures that the filter cartridge is optimized for performance, efficiency, and longevity.

Applications of SS Sintered Filter Cartridges

SS sintered filter cartridges are versatile and find applications in numerous industries

- Pharmaceuticals For sterile filtration of liquids and gases, ensuring that products are free of contaminants.

- Food and Beverage Used in processes such as brewing, juice clarification, and dairy filtration to maintain the quality and safety of food products.

- Chemical Processing Effective in filtering aggressive chemicals and solvents used in manufacturing processes.

- Oil and Gas Employed in upstream and downstream processes to ensure the purity and efficiency of oil and gas products.

Conclusion

In summary, SS sintered filter cartridges represent a sophisticated solution for many filtration challenges across different industries. Their inherent properties of durability, high filtration efficiency, and ease of cleaning make them a superior choice. As industries continue to demand higher quality and purity in their processes, the role of stainless steel sintered filter cartridges will only become more prominent. By investing in such advanced filtration technology, businesses can ensure smoother operations, reduce downtime, and enhance product quality, ultimately leading to greater customer satisfaction and commercial success.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: