Tel:

+8615930870079

Tel:

+8615930870079

нов . 24, 2024 07:38 Back to list

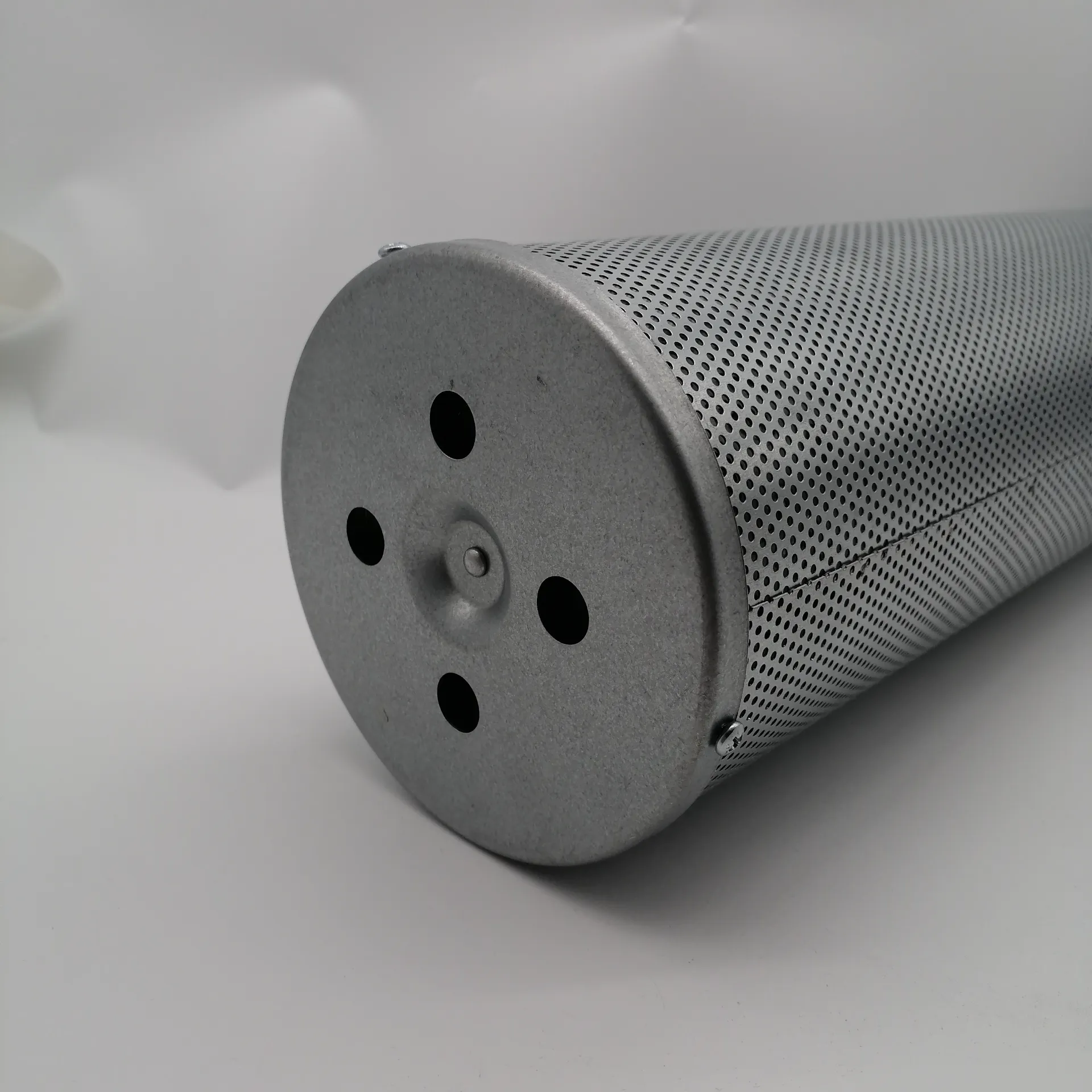

sintered metal filter cartridge

Sintered Metal Filter Cartridges An Overview of Benefits and Applications

In the realm of filtration technology, sintered metal filter cartridges have emerged as a cornerstone solution for a variety of industrial applications. Constructed from powdered metal materials that are subjected to high temperatures and pressures, these cartridges provide exceptional durability, efficiency, and versatility. This article explores the numerous advantages of sintered metal filter cartridges, their applications across different industries, and their overall significance in contemporary filtration systems.

What Are Sintered Metal Filter Cartridges?

Sintered metal filter cartridges are filtration devices made from sintered metal powders. The process of sintering involves heating the metal powders to a temperature below their melting point, allowing the particles to bond together without liquefying. This method results in a porous structure that possesses excellent mechanical strength and high resistance to thermal and chemical degradation. Common materials used for sintering include stainless steel, bronze, and other alloys, making these cartridges suitable for various harsh environments.

Key Advantages

1. Durability and Longevity One of the primary benefits of sintered metal filter cartridges is their robust nature. Unlike traditional filters made from paper or fabric, sintered metal filters are designed to withstand extreme conditions, including high temperatures and pressures. This durability translates to a longer lifespan, reducing the need for frequent replacements and ultimately lowering operational costs.

2. High Filtration Efficiency Sintered metal filters offer exceptional filtration performance. With a wide range of pore sizes available, these cartridges can effectively remove particulates, sediments, and other contaminants from liquids and gases. Their uniform pore distribution ensures consistent filtration and minimizes the risk of clogging.

3. Chemical Resistance Many sintered metal filter cartridges are designed to resist corrosive chemicals and can be used in applications involving aggressive solvents, acids, or alkalis. This characteristic makes them ideal for use in industries such as pharmaceuticals, petrochemicals, and food processing.

4. Ease of Cleaning and Reusability Another significant advantage is that sintered metal filters can be cleaned and reused numerous times. Whether through backwashing or chemical cleaning methods, these cartridges can maintain their filtration efficiency without requiring costly replacements. This feature not only promotes sustainability but also enhances the economic feasibility of using sintered metal filters.

sintered metal filter cartridge

5. Customizability Sintered metal filter cartridges can be customized to meet specific application requirements. Manufacturers can adjust parameters such as porosity, thickness, and shape to tailor the filter to particular operational needs. This flexibility makes them suitable for niche applications across various industries.

Applications Across Industries

Sintered metal filter cartridges are used in numerous sectors due to their versatility and effectiveness. Some notable applications include

- Oil and Gas Industry In oil recovery and refining processes, sintered metal filters are used to separate solids from liquids, ensuring product purity and operational efficiency. - Pharmaceutical Manufacturing These filters play a crucial role in the production of medicines, providing sterile filtration to prevent contamination during various stages of manufacturing.

- Food and Beverage Production In this industry, sintered metal cartridges are used to filter out unwanted particles from liquids, contributing to product safety and quality.

- Water Treatment Sintered metal filters are utilized in water purification processes, including drinking water treatment and wastewater management, where removal of impurities is critical.

- Chemical Processing With their ability to handle caustic materials without degradation, sintered metal filter cartridges are employed in various chemical processing applications.

Conclusion

In conclusion, sintered metal filter cartridges represent a sophisticated solution for filtration challenges across multiple industries. Their durability, efficiency, and reusability make them an excellent choice for companies seeking reliable filtration systems. As industries continue to evolve and demand higher filtration standards, sintered metal filters are poised to play an increasingly vital role in ensuring the purity and quality of products. Whether in demanding environments or sensitive manufacturing processes, sintered metal filter cartridges will continue to be indispensable tools in the pursuit of operational excellence.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: