Tel:

+8618931101301

Tel:

+8618931101301

нов . 05, 2024 01:10 Back to list

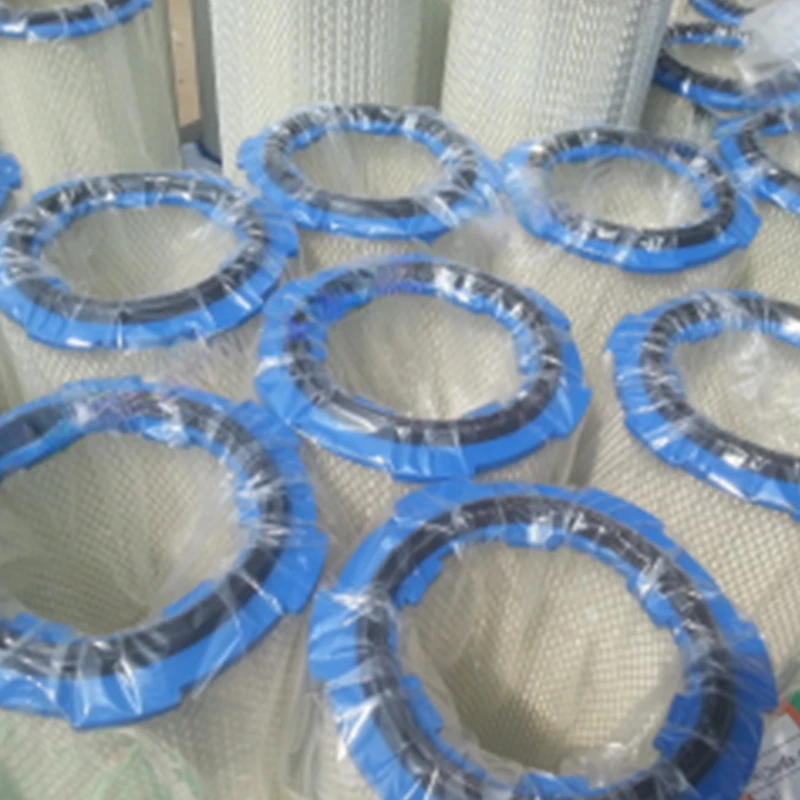

pleated filter cartridge dust collector

Pleated Filter Cartridge Dust Collector An Efficient Solution for Air Quality Management

As industrial processes continue to evolve, the demand for efficient air filtration systems has become increasingly crucial. One of the most effective solutions in this realm is the pleated filter cartridge dust collector. These systems are designed to capture and manage airborne particulate matter, ensuring not only compliance with regulatory standards but also the health and safety of workers within industrial environments.

Understanding Pleated Filter Cartridge Technology

At the heart of the pleated filter cartridge dust collector is a sophisticated filtering element characterized by its pleated design. Unlike traditional flat filters, pleated filters offer a significantly larger surface area to trap dust and other particles. This increased surface area allows for higher airflow rates while maintaining effective filtration, which means that the collector can operate more efficiently and for longer durations before necessitating maintenance or replacement.

The pleated design also enhances the cartridge's dust-holding capacity. As dust is collected, it creates a buffer on the surface of the filter, which further improves its efficiency by capturing even finer particles. The construction materials are generally engineered for durability and are often treated to resist moisture, chemicals, and extreme temperatures, thereby extending the lifespan of the filter cartridges.

Applications and Benefits

Pleated filter cartridge dust collectors are versatile systems used across various industries, including woodworking, metalworking, pharmaceuticals, food processing, and many others. Their primary function is to alleviate dust, smoke, and fume emissions, contributing to improved air quality both indoors and outdoors.

The benefits of employing these collectors are manifold

pleated filter cartridge dust collector

2. Regulatory Compliance Many industries are subject to stringent air quality regulations. Using an effective dust collection system helps ensure compliance with local, national, and international standards.

3. Cost-Efficiency Although the initial investment in a pleated filter cartridge dust collector may be higher than traditional systems, the reduced frequency of filter changes, coupled with lower energy consumption and maintenance costs, makes them a cost-effective solution over time.

4. Increased Equipment Lifespan By minimizing dust accumulation on machinery and equipment, these collectors help prolong the life of industrial equipment, leading to less downtime and repairs.

5. Versatile Design available in various sizes and configurations, pleated filter cartridge dust collectors can be tailored to fit specific operational needs, making them suitable for both small workshops and large-scale industrial facilities.

Maintenance and Best Practices

Proper maintenance is essential for maximizing the performance and longevity of pleated filter cartridge dust collectors. Regularly monitoring the differential pressure across the filters is crucial; a significant drop in pressure indicates that a cartridge may need cleaning or replacement. Furthermore, maintaining proper airflow and avoiding overloading the system can significantly enhance its efficiency.

In conclusion, pleated filter cartridge dust collectors represent a cutting-edge solution for managing particulate emissions in industrial settings. Their advanced design, coupled with significant operational benefits, makes them a preferred choice for companies seeking to improve air quality and comply with environmental regulations. As industries continue to face growing scrutiny regarding air pollution, the adoption of these efficient filtration systems is not just a practical investment but an essential step towards sustainable and responsible operations.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: