Tel:

+8615930870079

Tel:

+8615930870079

јан . 06, 2025 19:03 Back to list

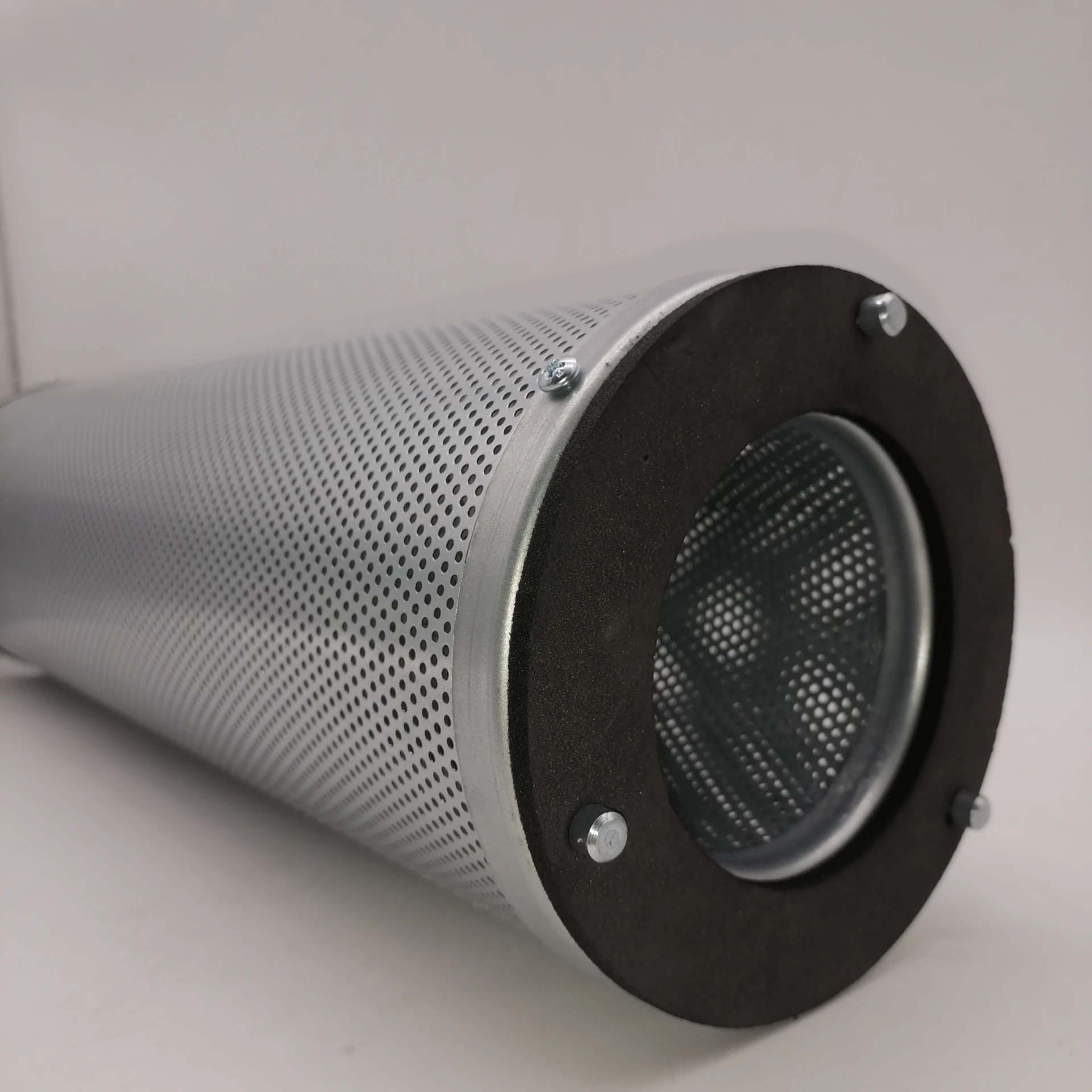

dust extractor cartridge filter

In the competitive world of industrial maintenance and air purification, selecting the right dust extractor filter cartridge can be pivotal. Not only do these cartridges play a critical role in ensuring the cleanliness of working environments, but they also impact the overall efficiency of dust extraction systems. Drawing from expert insights and practical experience, this article delves into the nuances of choosing the most effective dust extractor filter cartridge, focusing on ensuring optimal performance and longevity.

Every industry professional understands the importance of maintaining clean and healthy air standards. To achieve this, the dust extractor filter cartridge must be robust enough to handle specific industrial demands. The filtration efficiency of a cartridge significantly determines its effectiveness; hence, selecting a cartridge with high filtration rates is essential in environments with high dust generation. The material of the filter media—whether cellulose, polyester, or synthetic—is a critical factor influencing performance. Polyester filters, for instance, are renowned for their durability and efficiency, suitable for industries dealing with submicron particles.

Another aspect that underscores expertise in filter selection is the understanding of pressure drop. A lower initial pressure drop can lengthen the life of the filter, ensuring that systems do not have to overwork. When working with varying dust types and environmental conditions, it is advantageous to choose a filter capable of withstanding such variations without compromising air quality. This choice is often backed by empirical data derived from years of testing in different industrial environments.

Given the essential role these cartridges play, authoritativeness comes from the certification and compliance with industry standards. Reputable certifications, including HEPA and MERV ratings, are non-negotiable for industry leaders. These certifications guarantee that the filter will perform under specified conditions, fostering trust among buyers and reaffirming the credibility of the manufacturer. Regular compliance checks and third-party audits reinforce the filter’s standing in the market, providing an assurance of reliability to potential buyers.

dust extractor filter cartridge

The longevity and cost-effectiveness of a dust extractor filter cartridge are integral to its desirability. It is imperative to consider the total cost of ownership rather than just the initial purchase price. Filters that promise longer lifespans, easier maintenance, and reduced energy consumption might entail higher upfront costs but offer savings in the long run. Anecdotal experiences from professionals indicate that investing in quality filters results in fewer replacements and maintenance stoppages, contributing to significant cost reductions over time.

Trustworthiness, a pillar in product selection, is built through customer reviews and industry endorsements. Real-world applications and feedback further solidify the filter’s reputation. Case studies provide insights into the cartridge's performance in different scenarios, shedding light on its adaptability and reliability. Trust is deepened when manufacturers back their products with solid warranties and customer service, ready to assist in troubleshooting and ensuring user satisfaction.

Conclusively, navigating the selection process for a dust extractor filter cartridge involves a blend of expertise, experience, and credible manufacturer backing. The right filter not only guarantees cleaner air but also optimizes energy use, decreases maintenance frequency, and ultimately bolsters operational efficiency. Emphasizing these aspects in your selection criteria ensures that your industrial operations remain compliant, cost-effective, and committed to the health and safety of the workforce. Embracing such an informed approach promises a long-term partnership with air quality excellence.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: