Tel:

+8618931101301

Tel:

+8618931101301

нов . 08, 2024 20:01 Back to list

dust extractor cartridge filter

The Importance and Benefits of Dust Extractor Cartridge Filters

In various industries, controlling airborne dust and harmful particulates is a priority for ensuring worker safety and maintaining equipment efficiency. One effective solution that has gained popularity in recent years is the dust extractor cartridge filter. This technology is specifically designed to capture and filter out dust particles, improving air quality and extending the life of machinery.

What are Dust Extractor Cartridge Filters?

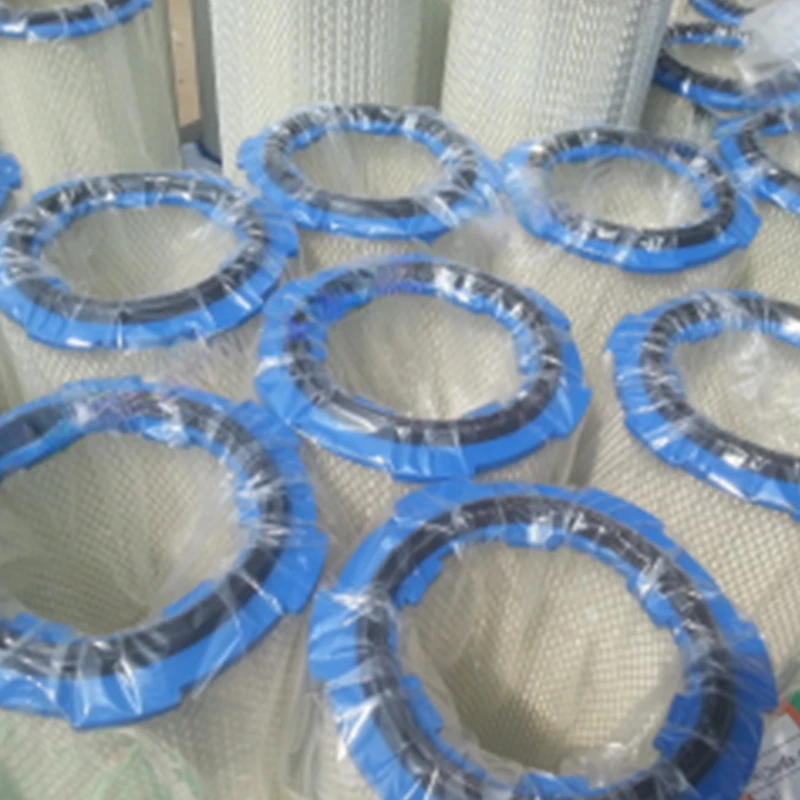

Dust extractor cartridge filters are specialized filtration systems utilized in industrial dust collection equipment. These filters come in cylindrical shapes, designed to accommodate a high volume of air and efficiently trap particulates. They typically use advanced filter media, which can provide high filtration efficiency for finer particles that traditional bag filters may struggle to retain. The cartridge design allows for easy replacement and maintenance, making them a practical choice for various applications.

How Do They Work?

The operation of dust extractor cartridge filters is straightforward yet highly effective. As dusty air enters the filtration system, it is directed through the cartridge, where it passes through the filter media. The design of the media promotes the mechanical capture of particulate matter, allowing clean air to exit the extractor. Built-in features, such as pulse jet cleaning systems, can periodically remove accumulated dust from the filter’s surface, ensuring consistent performance over time. This cleaning mechanism helps maintain airflow and filter efficiency, thus enhancing operational longevity.

Benefits of Using Dust Extractor Cartridge Filters

1. Enhanced Air Quality One of the primary benefits of integrating dust extractor cartridge filters into an industrial setting is the significant improvement in air quality. By efficiently removing airborne dust and particulates, these filters help provide a safer work environment. This is particularly crucial for industries that are prone to produce hazardous dust, such as woodworking, metalworking, and construction.

dust extractor cartridge filter

2. Increased Equipment Longevity Dust and particulates can cause wear and tear on machinery, leading to costly downtime and repairs. By incorporating effective dust extraction systems featuring cartridge filters, businesses can protect their investments and reduce maintenance costs. Clean air not only protects equipment but also enhances operational efficiency.

3. High Filtration Efficiency Dust extractor cartridge filters are designed to provide exceptional filtration efficiency, capturing fine dust particles that other filters might miss. This capability is critical for industries that require a clean environment to adhere to safety and quality regulations.

4. Space-Saving Design The compact and cylindrical design of cartridge filters allows them to fit into smaller spaces compared to traditional filtration systems. This characteristic is especially beneficial for facilities with limited space or those looking to optimize their layout.

5. Versatility and Customization Dust extractor cartridge filters can be tailored to meet specific operational needs across various industries. Different filter media types and configurations are available, enabling companies to select the most appropriate solution for their unique dust challenges.

6. Lower Energy Consumption Modern cartridge filters are designed with energy efficiency in mind. Their ability to maintain airflow with lower resistance can lead to reduced energy costs, making them an environmentally friendly option.

Conclusion

In summary, dust extractor cartridge filters play a critical role in ensuring cleaner air quality and protecting machinery within industrial environments. Their design provides high-efficiency filtration while minimizing maintenance and operational costs. As industries continue to prioritize health and safety alongside productivity, investing in advanced dust extraction solutions, such as cartridge filters, becomes increasingly essential. By adopting this technology, businesses can create a safer workplace and foster a culture of care for both employees and equipment.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: