Tel:

+8618931101301

Tel:

+8618931101301

нов . 08, 2024 04:29 Back to list

Efficient Air Filter Cartridges for Dust Collector Systems and Enhanced Air Quality

Understanding Dust Collector Air Filter Cartridges

In various industrial settings, dust collector air filter cartridges play an essential role in maintaining air quality and ensuring a safe work environment. These cartridges are critical components of dust collection systems designed to capture particulate matter, providing cleaner air and reducing health risks for workers exposed to hazardous dust particles. This article delves into the function, types, and maintenance of dust collector air filter cartridges.

Function of Dust Collector Air Filter Cartridges

Dust collector air filter cartridges serve the primary function of filtering dust, powder, and other airborne contaminants from the air. When an industrial process generates dust, it can be harmful not only to the environment but also to the health of employees working in that space. The cartridges trap these particles, allowing clean air to be returned to the atmosphere. This filtration process is vital for compliance with health and safety regulations, protecting workers from respiratory issues and other health concerns associated with poor air quality.

The efficiency of a dust collector primarily depends on its filter cartridges. These filters are designed to have a large surface area, which enables them to capture more dust without clogging quickly. This design allows for continuous operation of the dust collection system while minimizing downtime related to filter replacement.

Types of Dust Collector Air Filter Cartridges

There are various types of dust collector air filter cartridges available on the market, each designed for specific applications and types of airborne contaminants. The most common types include

1. Cellulose Cartridges Made from natural fibers, cellulose cartridges are ideal for filtering dry dust and are often used in applications with less sticky particulates. While they are cost-effective, they may not perform as well in very high humidity or oily conditions.

2. Polyester Cartridges These synthetic filters boast improved durability and higher filtration efficiency than cellulose. They are suitable for a wide range of applications, including woodworking and metalworking, where finer particles and moisture may be present.

3. PTFE (Teflon) Membrane Cartridges For applications that expose the filter to sticky and aggressive dust, PTFE membrane cartridges are preferred. These filters provide excellent resistance to abrasion and chemicals, maintaining performance in challenging conditions.

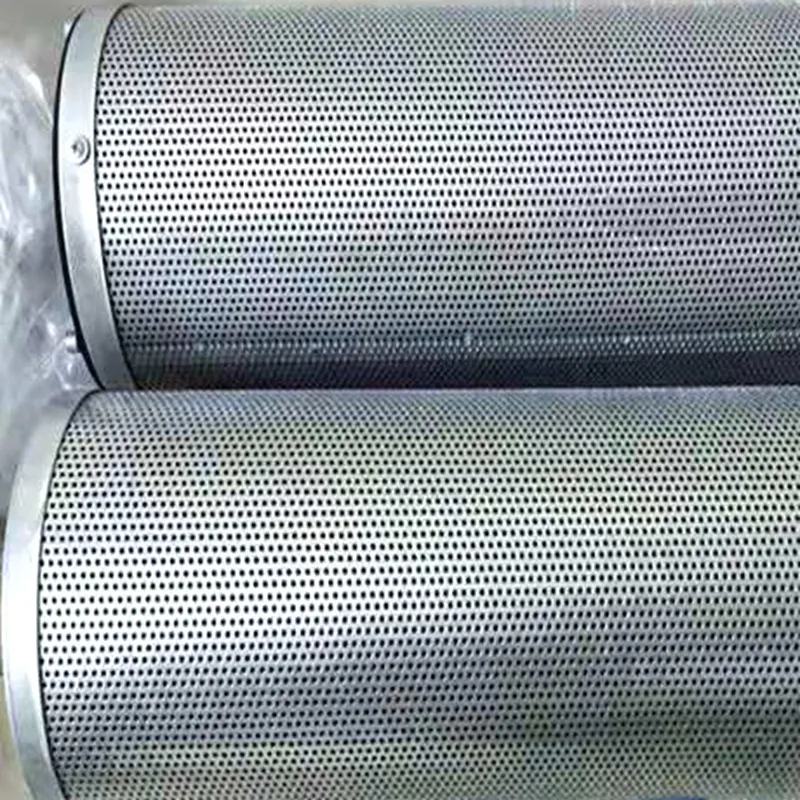

dust collector air filter cartridge

4. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are capable of capturing at least 99.97% of particles that are 0.3 microns or larger. These are often utilized in environments requiring ultra-clean air, such as pharmaceutical manufacturing or semiconductor production.

5. Carbon Filters In some situations, it might be necessary to eliminate odors or volatile organic compounds (VOCs) from the air. Carbon filters, which use activated carbon to adsorb these contaminants, can be included alongside traditional filters for comprehensive air purification.

Maintenance of Dust Collector Air Filter Cartridges

Regular maintenance of dust collector air filter cartridges is critical to ensure their efficiency and longevity. The maintenance practices include

1. Routine Inspection Regularly check the cartridges for signs of damage, wear, or excessive dirt accumulation. Identifying issues early can prevent costly downtime and air quality problems.

2. Cleaning Some cartridges can be cleaned and reused, while others are designed for single-use. For reusable models, employ appropriate methods such as compressed air to dislodge particles without damaging the filter.

3. Timely Replacement Establish a schedule for replacing filter cartridges based on operational data, manufacturer recommendations, and inspection results. Waiting too long can lead to reduced efficiency and increased energy costs.

4. Documentation Keep records of inspections, cleaning, and replacements to track filter performance and assist in compliance with regulatory standards.

Conclusion

Dust collector air filter cartridges are indispensable for maintaining clean air in industrial environments. By understanding their functions, types, and proper maintenance, businesses can enhance air quality, ensure worker safety, and comply with environmental regulations. Investing in high-quality filter cartridges and establishing a robust maintenance program not only protects employees but also contributes to the overall efficiency and sustainability of industrial operations.

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

Email:

Email: