Tel:

+8615930870079

Tel:

+8615930870079

дец . 10, 2024 05:14 Back to list

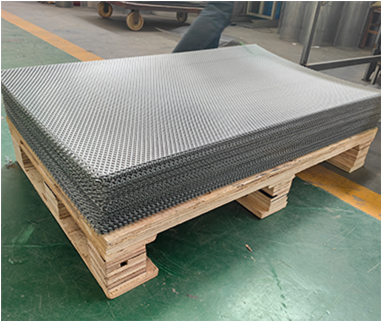

dust cartridge

Understanding Dust Cartridge Filters A Guide to Cleaner Air

In an age where air quality is paramount for health and wellbeing, dust cartridge filters have emerged as essential components in various industrial and commercial applications. These filters play a critical role in capturing particulate matter, ensuring cleaner air for both workers and the environment. In this article, we delve into the design, function, and importance of dust cartridge filters in pollution control and air quality management.

What is a Dust Cartridge Filter?

A dust cartridge filter is a cylindrical filtration device designed to remove dust and particulate contaminants from air or gas streams. These filters are typically made of fabric or other filter media that trap particles while allowing clean air to pass through. They are widely used in industries such as manufacturing, pharmaceuticals, food processing, and woodworking, where dust accumulation can be hazardous to health and equipment.

How Do Dust Cartridge Filters Work?

The operation of dust cartridge filters is based on the principles of mechanical filtration

. As contaminated air enters the filter, larger particles are trapped on the surface of the filter medium, while smaller particles penetrate deeper into the material. Over time, as more dust collects, the filter develops a dust cake, which can actually enhance the filter's efficiency by providing additional layers for particle capture.Regular maintenance is crucial to ensure optimal performance. Filters need to be cleaned or replaced periodically to prevent excessive pressure drop, which can hinder airflow and reduce the system’s effectiveness. Some systems utilize automated pulse jet cleaning, where bursts of air are directed into the filter to remove accumulated dust, allowing for continuous operation and extended filter life.

Importance of Dust Cartridge Filters

dust cartridge

1. Health and Safety The primary benefit of dust cartridge filters is their ability to improve air quality. By capturing harmful particulates, these filters reduce the risk of respiratory issues, allergies, and other health problems for workers exposed to dust-laden environments. This is particularly critical in industries where hazardous materials are handled.

2. Environmental Compliance Regulatory standards regarding air quality are becoming increasingly stringent. Industries must adhere to these regulations to avoid penalties and ensure public health. Dust cartridge filters can help companies meet compliance standards by minimizing emissions of particulate matter into the atmosphere.

3. Equipment Protection Dust accumulation can cause significant wear and tear on machinery. By filtering out dust, cartridge filters help prolong the life of industrial equipment, reducing maintenance costs and downtime. This leads to increased efficiency and productivity in operations.

4. Energy Efficiency Clean air systems operate more efficiently. When dust cartridges are well-maintained and functioning optimally, they reduce the load on fans and blowers, resulting in lower energy consumption. This not only benefits the environment but also contributes to lower operational costs.

Conclusion

In summary, dust cartridge filters are indispensable tools in maintaining air quality across various industries. Their ability to capture a wide range of particulate matter helps protect the health of workers, ensures compliance with environmental regulations, and safeguards equipment from dust-related damage. As industries continue to focus on sustainable practices and improved health standards, the importance of effective filtration systems like dust cartridges will only increase.

Investing in high-quality dust cartridge filters and implementing a regular maintenance schedule can yield significant long-term benefits, making them a vital component of modern industrial operations. For any business seeking to enhance its air quality management practices, understanding and utilizing dust cartridge filters is a critical step.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: