Tel:

+8618931101301

Tel:

+8618931101301

окт . 18, 2024 12:16 Back to list

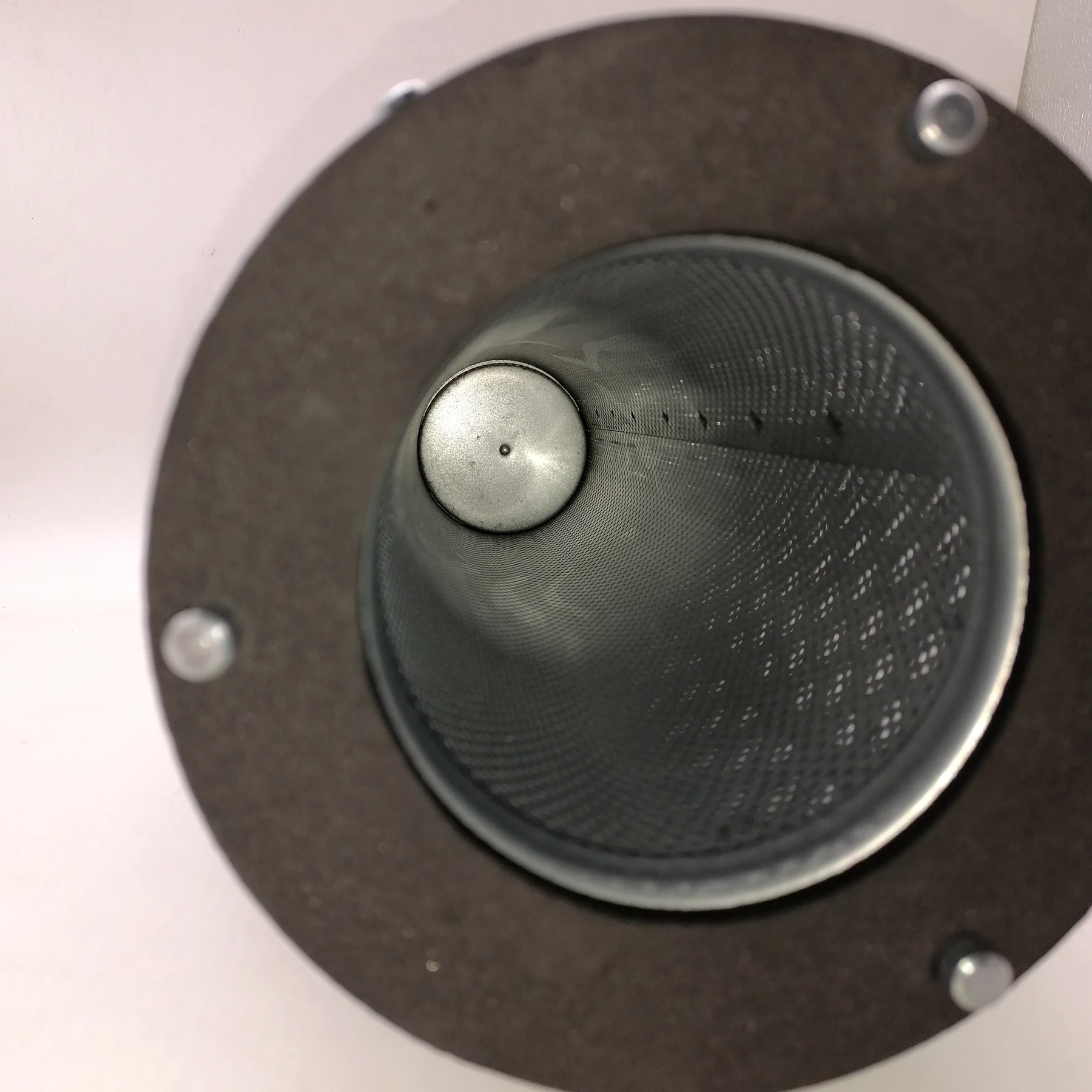

Efficient Cartridge Vacuum Filter Solutions for Enhanced Filtration Performance

Understanding Cartridge Vacuum Filters Principles and Applications

Cartridge vacuum filters have emerged as a vital technology in various industries, providing efficient and reliable solutions for liquid-solid separation processes. These filters are widely used in applications ranging from wastewater treatment to chemical processing, food and beverage production, and mineral processing. In this article, we will explore the principles governing cartridge vacuum filters, their components, advantages, and applications.

Principles of Operation

At the core of any filtration technology is the fundamental principle of separating solid particles from a liquid medium. Cartridge vacuum filters operate by creating a vacuum that draws liquid through a filtering medium, typically a permeable cartridge. The basic mechanism involves three main steps

1. Preparation The slurry, which is a mixture of solids and liquids, is fed into the filtration system. The vacuum is generated using a pump that creates a pressure differential.

2. Filtration As the vacuum pulls the liquid through the filter cartridge, solids are trapped on the surface of the cartridge. The design of the cartridge, including its porosity and surface area, influences the efficiency of filtration and the quality of the separated solids.

3. Clean-up Once the filtration process is complete, the trapped solids can be removed by backflushing or mechanical scraping, depending on the design of the system.

Components of Cartridge Vacuum Filters

Cartridge vacuum filters consist of several critical components

- Filter Cartridge This is the core component where filtration occurs. Cartridges can be made from various materials, including polyester, polypropylene, and ceramic, depending on the application and the nature of the slurry.

- Pump The vacuum pump creates the suction necessary to draw liquid through the filter. The type of pump will vary based on the required pressure and flow rate.

- Stainless Steel Housing The filter is usually housed in a durable casing that can withstand the pressures and conditions of the filtration process.

- Control System Modern systems are often equipped with sensors and controls that monitor the process parameters, allowing for automatic adjustments to optimize performance.

Advantages of Cartridge Vacuum Filters

cartridge vacuum filter

Cartridge vacuum filters offer several benefits

1. Efficiency These filters provide a high surface area-to-volume ratio, enabling them to handle large quantities of slurry while maintaining excellent filtration efficiency.

2. Cost-effectiveness With their design, cartridge filters can be more economical to operate compared to traditional methods, as they reduce labor and maintenance costs.

3. Versatility They can be utilized across various industries and are adaptable to different slurry types, including viscous solutions and abrasive materials.

4. Quality of Filtration The filtration process can be customized to various specifications, ensuring the removal of unwanted particles and enhancing the quality of the output.

5. Easy Maintenance Cartridge vacuum filters are designed for ease of maintenance and replacement. When a cartridge becomes clogged or worn, it can typically be replaced without significant downtime.

Applications

The versatility of cartridge vacuum filters means they find applications in numerous sectors

- Wastewater Treatment In this industry, these filters help in separating contaminants from treated water, ensuring compliance with environmental regulations.

- Food and Beverage They are used for clarifying juices and oils, separating solids from liquids to enhance product quality.

- Mining and Minerals The filtration process is crucial in mineral recovery operations, where valuable materials need to be separated from slurries.

- Pharmaceuticals Ensuring purity and compliance with stringent regulations necessitates efficient filtration systems in drug manufacturing processes.

In conclusion, cartridge vacuum filters are essential tools in many industrial applications, offering efficient solutions for solid-liquid separation. Their operational principles, combined with their advantages, make them an ideal choice for various processes, enhancing productivity and ultimately contributing to improved product quality. As industries continue to evolve and face new challenges, the role of advanced filtration technologies like cartridge vacuum filters will undoubtedly remain significant.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: