Tel:

+8618931101301

Tel:

+8618931101301

Nën . 06, 2024 19:28 Back to list

Air Filters for Turbocharged Engine Intake Systems in Automotive Applications

Turbine Air Intake Filters Ensuring Optimal Performance and Longevity

In the world of aviation and industrial engineering, the performance of turbines is pivotal to efficiency and productivity. One of the critical components that play an essential role in maintaining this performance is the air intake filter. Specifically designed for turbines, air intake filters serve as the first line of defense against contaminants that can affect engine performance, longevity, and overall reliability.

Understanding the Function of Air Intake Filters

Air intake filters are designed to clean the air before it enters the turbine engine. Turbine engines, whether in aircraft or power generation systems, require a consistent flow of clean air to operate efficiently. The primary function of these filters is to trap particulate matter, such as dust, dirt, and debris, ensuring only clean air reaches the engine. This is crucial, as any contaminants can lead to a host of issues, including corrosion, reduced efficiency, and even catastrophic engine failure.

Types of Turbine Air Intake Filters

There are various types of turbine air intake filters available, and selecting the right one depends on several factors, including the operating environment and specific turbine application. The main types include

1. Foam Filters Often made from polyurethane or polyester, foam filters are highly effective at capturing large particles. They are typically washable and reusable, making them a cost-effective option for many applications.

2. Paper Filters These filters are generally made from cellulose or synthetic fibers. They are known for their high filtration efficiency and are widely used due to their affordability. However, they are usually single-use and must be replaced regularly.

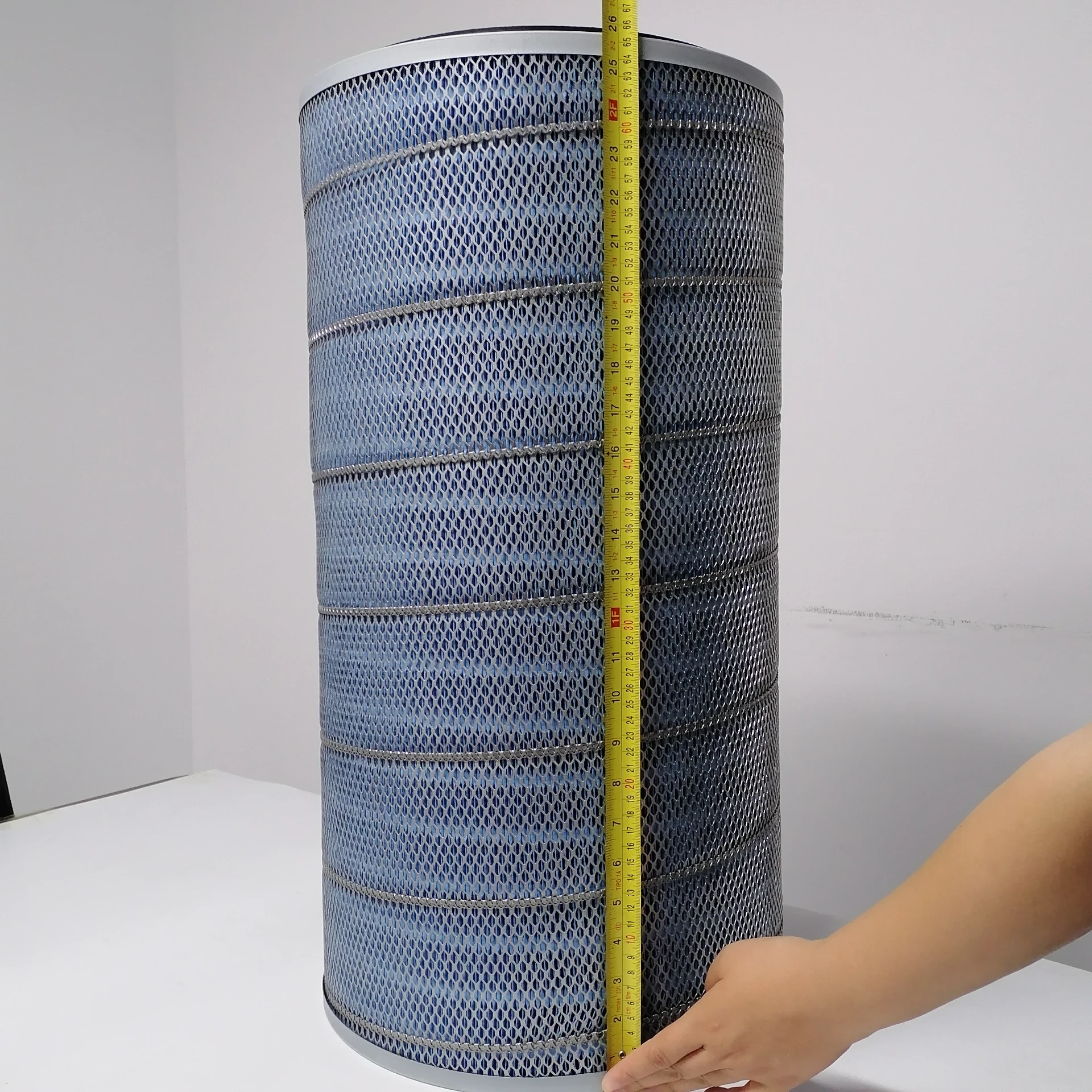

3. Metal Mesh Filters Constructed from stainless steel or aluminum, metal mesh filters are durable and resistant to damage. They can capture larger particles and are often used in environments where higher temperatures and pressures are present.

4. Panel Filters These filters are often found in larger turbines. They provide a high level of filtration and can be customized to fit specific turbine designs. Panel filters are typically made of synthetic media and provide good airflow while effectively trapping contaminants.

turbine air intake filters

5. High-Efficiency Particulate Air (HEPA) Filters In applications where ultra-clean air is required, HEPA filters are utilized. These filters provide a very high level of filtration efficiency, removing 99.97% of particles that are 0.3 micrometers in size or larger.

Importance of Regular Maintenance

Maintaining turbine air intake filters is crucial for optimal performance. Over time, filters can become clogged with dirt and debris, restricting airflow and decreasing engine performance. Regular inspection and replacement or cleaning of filters can enhance turbine efficiency and prevent costly repairs.

Operators must monitor filter conditions and airflow regularly. Many advanced turbine systems integrate airflow sensors that alert operators when filter replacement is necessary. Ignoring these signals can lead to reduced engine performance, increased fuel consumption, and ultimately, engine damage.

Challenges and Considerations

Operating environments can significantly impact the effectiveness of air intake filters. For instance, turbines in arid regions may face high dust levels, calling for filters with higher dust-loading capacity. Conversely, turbines in humid environments may need filters that can withstand moisture without degrading.

Additionally, manufacturers should consider the impact of filters on engine performance. While higher efficiency filters can provide superior filtration, they may also introduce more resistance to airflow. Therefore, a balance must be struck between filtration efficiency and engine performance, and selecting the right filter type and design is vital.

Conclusion

In conclusion, turbine air intake filters play a fundamental role in ensuring the efficiency and longevity of turbine engines. By capturing harmful particulates before they enter the engine, these filters protect against potential damage and maintain optimal performance. Regular maintenance and appropriate selection based on environmental factors are crucial to deriving the maximum benefits from air intake filtration systems. As technology continues to advance, we can expect further improvements in filter designs that enhance performance while facilitating engine reliability in diverse operating conditions. The future of turbine performance may very well depend on the humble yet essential air intake filter.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: