Tel:

+8615930870079

Tel:

+8615930870079

Tet . 14, 2024 11:50 Back to list

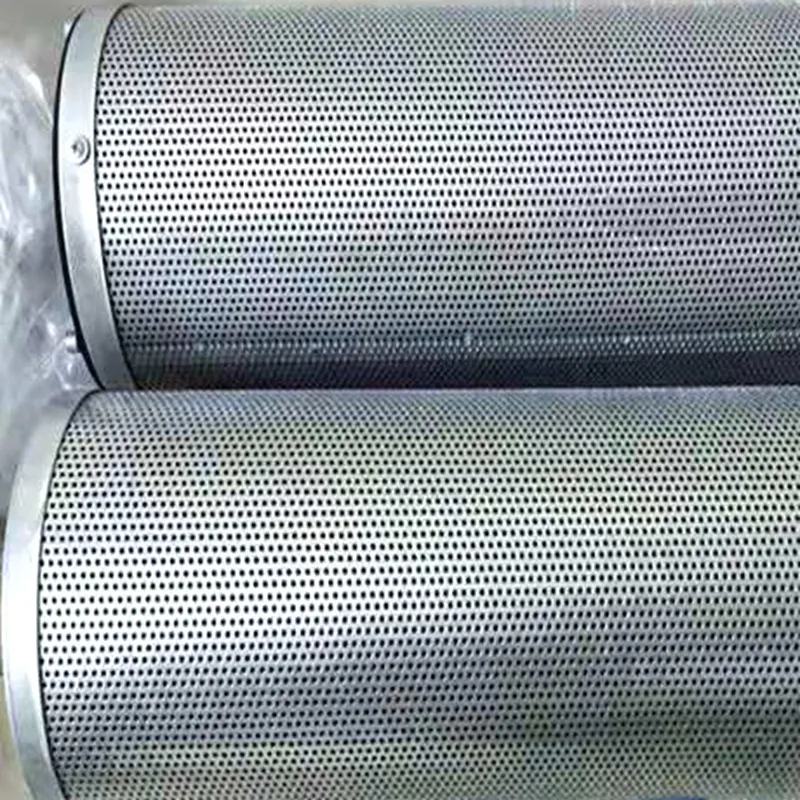

turbine air intake filters

The Importance of Turbine Air Intake Filters

Turbine air intake filters play a crucial role in the performance and efficiency of gas turbine engines, which are widely used in power generation, aviation, and various industrial applications. These filters serve a fundamental purpose to ensure that the air entering the turbine is clean and free from contaminants that could potentially damage the engine or impair its functionality. This article delves into the reasons why turbine air intake filters are essential, the types available, and best practices for maintenance.

Function and Importance

Gas turbines operate by drawing in air, compressing it, mixing it with fuel, and igniting the mixture to produce thrust or energy. The quality of the incoming air is vital to the engine's performance. Contaminants such as dust, sand, and other particulate matter can cause wear and tear on the turbine blades and other internal components. This degradation can lead to reduced efficiency, increased maintenance costs, and even catastrophic engine failure in severe cases.

Moreover, clean air ensures optimal combustion conditions, which not only improves the overall efficiency of the engine but also minimizes emissions. In an era where environmental considerations are paramount, maintaining low emissions is crucial for compliance with regulations and for promoting sustainability.

Types of Air Intake Filters

There are several types of turbine air intake filters designed to meet different operational requirements and environmental conditions

1. Panel Filters These are flat filters often used in commercial and industrial applications. They effectively capture large particles and allergens.

3. Pre-filters Used in conjunction with main filters, pre-filters capture larger particles and extend the life of primary filters. They are especially useful in harsh environments with high particulate loads.

turbine air intake filters

4. High-Efficiency Particulate Air (HEPA) Filters These are used in more sensitive applications where clean air is critical, providing a high level of filtration that captures up to 99.97% of particles.

Maintenance Best Practices

To ensure the longevity and effectiveness of turbine air intake filters, regular maintenance is imperative. Here are some best practices

1. Routine Inspections Conduct regular checks to assess the condition of the filters. Look for signs of clogging or damage that could impair performance.

2. Scheduled Replacements Depending on the operational environment, filters should be replaced at predetermined intervals to ensure they continue to function effectively. This timeframe might vary depending on exposure to high dust levels or other pollutants.

3. Cleaning Some filters can be cleaned and reused. Follow manufacturer guidelines for cleaning to avoid damage while maintaining filtration effectiveness.

4. Monitoring Airflow Keep track of the airflow rates to the turbine. A decrease in airflow can indicate a clogged filter that necessitates immediate attention.

5. Environmental Considerations Understand the specific environmental conditions your turbine operates in, as this influences the type of filter required and maintenance frequency.

Conclusion

In conclusion, turbine air intake filters are indispensable components that significantly affect the performance, efficiency, and longevity of gas turbine engines. As the demand for reliable and efficient energy sources continues to rise, understanding the importance of these filters and implementing effective maintenance practices will be essential in optimizing turbine operations. Investing in high-quality filtration systems and adhering to a rigorous maintenance schedule can lead to enhanced reliability and reduced operational costs, making it a prudent choice for any turbine operator.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: