Tel:

+8618931101301

Tel:

+8618931101301

Nën . 18, 2024 15:05 Back to list

stainless steel filter element

The Importance of Stainless Steel Filter Elements in Modern Filtration Systems

In today's industries, the need for efficient filtration systems cannot be overstated. From water treatment plants to food and beverage production, the quality of the end product is heavily dependent on the effectiveness of filtration processes. One of the most significant components of these filtration systems is the filter element, with stainless steel filter elements standing out as a durable and reliable choice.

What are Stainless Steel Filter Elements?

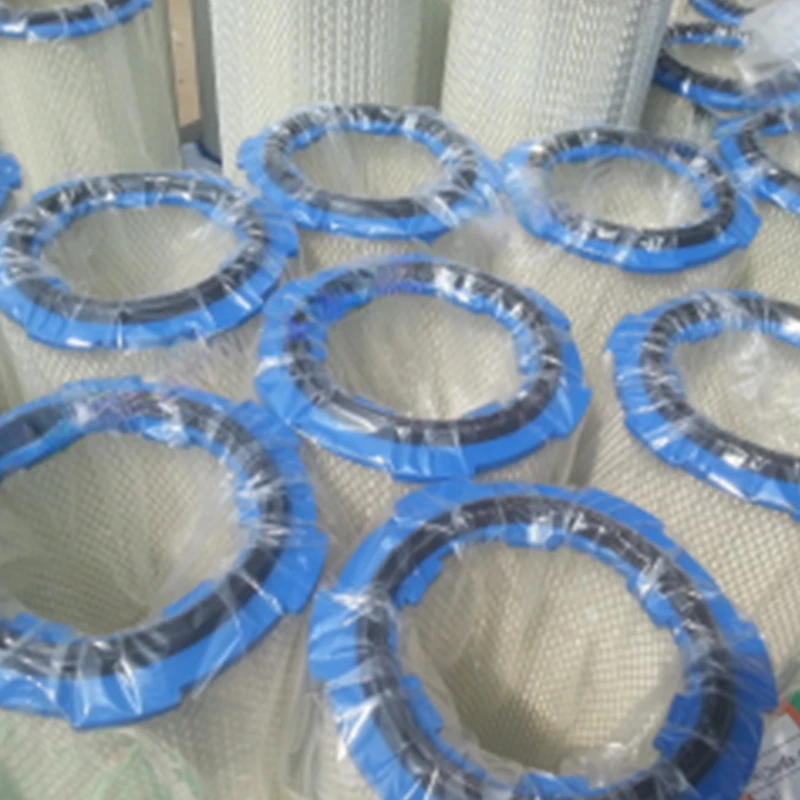

Stainless steel filter elements are components used in various filtration systems to remove particulates, contaminants, and impurities from fluids or gases. Made from stainless steel, a corrosion-resistant alloy, these filter elements are well-suited for harsh environments where traditional filters might fail. Their resilient nature allows them to withstand high temperatures and pressures, making them ideal for a range of applications.

Advantages of Stainless Steel Filter Elements

1. Durability and Longevity One of the primary advantages of stainless steel filter elements is their durability. Unlike paper or cloth filters, stainless steel can endure repetitive cleaning and does not degrade over time. This longevity translates into lower replacement costs and less downtime for maintenance, making them a cost-effective option in the long run.

2. Corrosion Resistance Stainless steel is inherently resistant to rust and corrosion, which is crucial when filtering aggressive liquids or gases. This property ensures that the filter maintains its integrity and functionality even in challenging environments, such as chemical manufacturing or marine applications.

3. High Filtration Efficiency Stainless steel filter elements can be designed to achieve various filtration ratings, allowing them to capture a wide range of particle sizes. This versatility enables industries to tailor their filtration systems according to specific needs, ensuring optimal performance and product quality.

stainless steel filter element

4. Easy to Clean and Reusable Many stainless steel filter elements are designed for easy cleaning, often being backwashable or can be cleaned manually. This feature not only extends the lifespan of the filter but also reduces waste and the need for frequent replacements, aligning with sustainable practices.

5. Temperature Resistance Stainless steel can withstand high temperatures, making it suitable for applications such as oil and gas extraction or hot water systems. This thermal resilience ensures that the filter maintains its structure and performance, regardless of the conditions.

6. Customizable Designs Manufacturers can create stainless steel filter elements in various shapes and sizes to meet specific application requirements. Customization allows industries to optimize their filtration systems further and enhance operational efficiency.

Applications of Stainless Steel Filter Elements

Stainless steel filter elements find use across a plethora of industries. In the food and beverage sector, they are used to ensure product purity and safety by removing contaminants from liquids. In pharmaceuticals, these filters play a crucial role in maintaining sterile environments during production processes. In water treatment, stainless steel filters help improve water quality by effectively removing sediments and harmful particles.

Moreover, in the automotive and aerospace industries, these filter elements are essential in maintaining the efficiency of fuel systems and hydraulic fluids. Their ability to perform under high pressures and temperatures ensures that critical machinery operates reliably.

Conclusion

Stainless steel filter elements are a vital component of modern filtration systems, offering unmatched durability, efficiency, and versatility. Their corrosion resistance and high-temperature capabilities make them suitable for a variety of industries and applications. As businesses continue to prioritize sustainability and cost-effectiveness, the demand for stainless steel filter elements is expected to grow. By investing in these high-quality filtration solutions, industries can ensure superior product quality, enhance operational efficiency, and contribute to a more sustainable future.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: