Tel:

+8615930870079

Tel:

+8615930870079

Gus . 30, 2024 06:34 Back to list

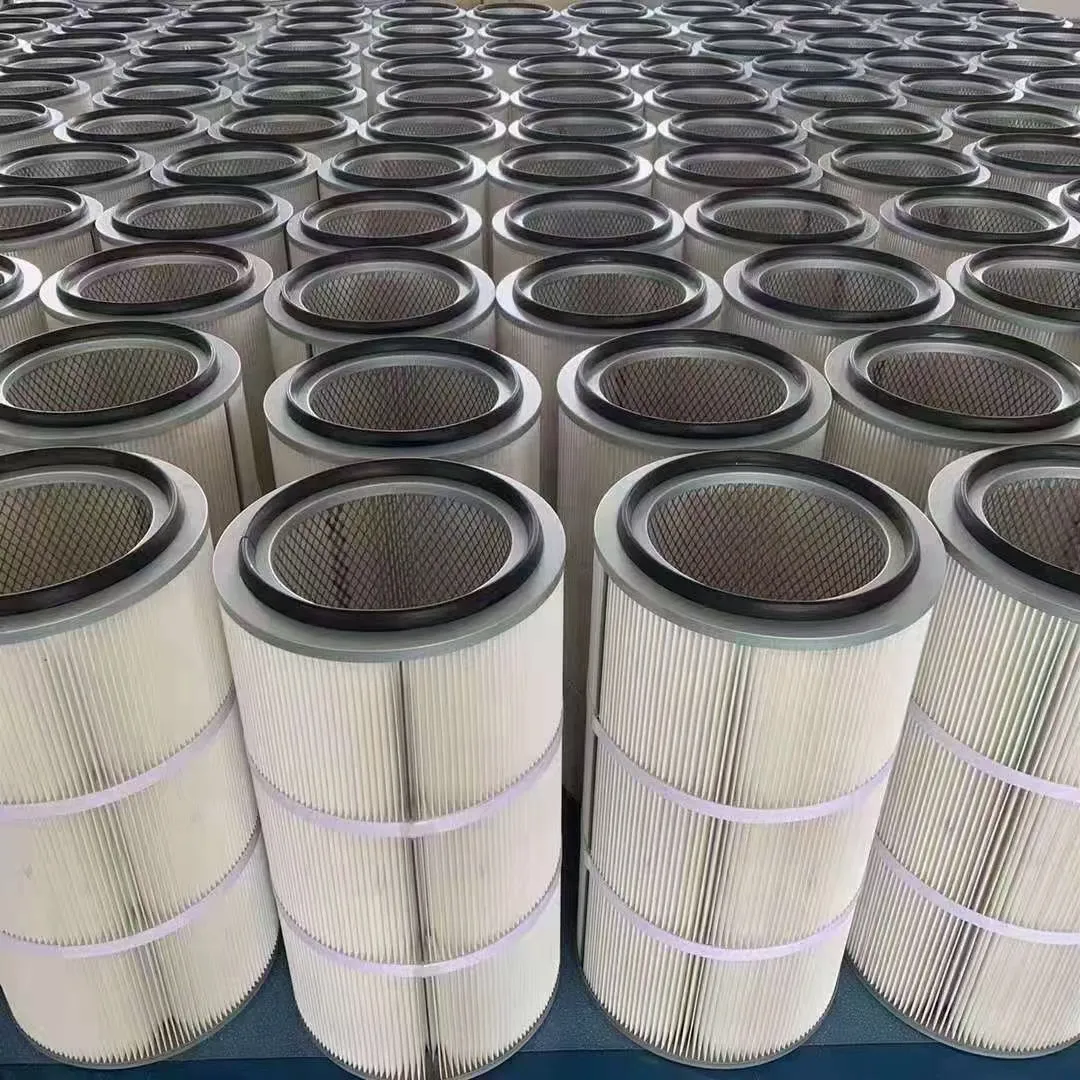

High-Performance Sintered Metal Filter Cartridges for Industrial Applications

Sintered Metal Filter Cartridges The Optimal Solution for Filtration Needs

Sintered metal filter cartridges have emerged as a paramount solution in various industrial applications where high performance and durability are key requirements. These cartridges are crafted from porous metal, often stainless steel, through a process known as sintering—where metal powder is compacted and heated to create a solid structure, retaining porosity for effective filtration.

One of the standout features of sintered metal filter cartridges is their ability to handle a wide range of temperatures and pressures. Unlike traditional filters made from paper or other porous materials, sintered metal cartridges maintain structural integrity even under extreme conditions. This makes them particularly suitable for industries like oil and gas, chemical processing, and pharmaceuticals, where filtration processes can be challenging and demanding.

The filtration capabilities of sintered metal cartridges are impressive. They are designed to capture particulate matter ranging from microns to larger particles, effectively removing contaminants and ensuring the purity of the fluid being processed. The uniform pore size, achieved during the sintering process, allows for controlled filtration and minimizes the risk of clogging—a common issue faced with conventional filters. Moreover, their longevity and resistance to chemical reactions significantly reduce replacement frequency, leading to lower operational costs over time.

Ease of cleaning and maintenance is another significant advantage of sintered metal filters. They can be cleaned and reused multiple times, unlike disposable filters that contribute to waste and require frequent replacements. The ability to backwash or perform chemical cleaning further ensures that these cartridges maintain their efficiency throughout their lifecycle.

sintered metal filter cartridge

In addition to their practical benefits, sintered metal filter cartridges are environmentally friendly. By reducing waste generated from disposable filters and utilizing recyclable materials, they align well with modern sustainability goals. Industries are increasingly aware of their environmental impact, and opting for sintered filters can be a step towards more responsible practices.

Moreover, customization options for sintered metal filter cartridges are extensive. Depending on specific application requirements, these cartridges can be tailored in terms of pore size, dimensions, and materials, making them suitable for a myriad of applications. Whether it’s for water filtration, air purification, or in specialized machinery, sintered metal filters provide flexible solutions that meet diverse industrial needs.

As industries continue to evolve, so do their filtration requirements. The demand for high-efficiency, durable, and environmentally responsible solutions has led to the growing popularity of sintered metal filter cartridges. Their capacity to deliver consistent performance, reduce downtime, and lower operational costs positions them as an invaluable component in modern filtration systems.

In summary, sintered metal filter cartridges represent an advanced filtration solution for a variety of industries. With their durability, efficiency, and customizable features, they are ideally suited to meet the rigorous demands of contemporary filtration applications, making them a smart investment for businesses looking to enhance their operational efficiency and environmental responsibility. As technology progresses and industries advance, the role of sintered metal filters will undoubtedly expand, continuing to redefine filtration standards across sectors.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: