Tel:

+8615930870079

Tel:

+8615930870079

Dhj . 10, 2024 04:49 Back to list

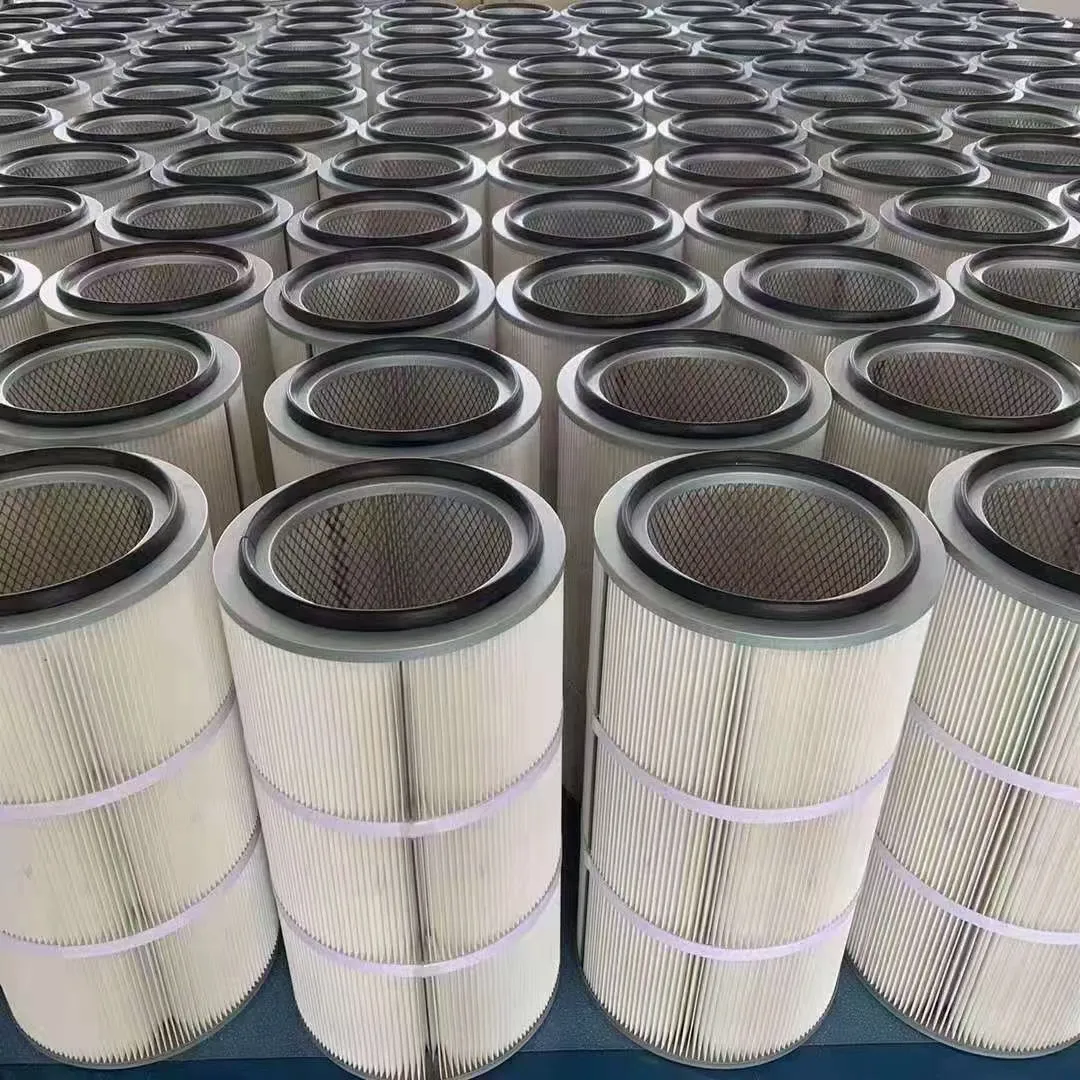

silo filter cartridge

Understanding Silo Filter Cartridges Importance and Applications

In various industries, efficient filtration systems play a critical role in maintaining the quality and integrity of the products. Among the diverse filtration solutions available, silo filter cartridges stand out due to their specialized design and functionality. This article delves into the importance and applications of silo filter cartridges, offering insights into their effectiveness in industrial processes.

What are Silo Filter Cartridges?

Silo filter cartridges are specialized filtration devices designed to remove impurities from bulk materials stored in silos. These cartridges typically feature a cylindrical shape, allowing them to be fitted into filter housings at the top of storage silos. As air is expelled from the silo during material discharge, the filter cartridges trap dust particles and contaminants, ensuring that only clean air is released into the environment. This not only protects the air quality but also helps in maintaining compliance with environmental regulations.

Importance of Silo Filter Cartridges

1. Environmental Protection One of the primary reasons for the use of silo filter cartridges is to safeguard the environment. By filtering out harmful particles and preventing them from being released into the atmosphere, these cartridges help minimize air pollution. This is increasingly crucial as industries face stricter regulations regarding emissions and waste.

2. Product Integrity In industries that handle sensitive materials, such as food processing or pharmaceuticals, maintaining product integrity is paramount. Silo filter cartridges effectively capture dust and contaminants that could compromise product quality. For instance, in a food processing plant, any foreign particles can lead to contamination, potentially resulting in health risks for consumers. Thus, silo filter cartridges are essential for ensuring the purity of the materials stored.

3. Operational Efficiency The efficient operation of silos is another significant benefit of using silo filter cartridges. Without proper air filtration, dust buildup can occur in the storage or handling equipment, leading to clogs and inefficiencies. By keeping the airflow clean and unobstructed, these cartridges help maintain the smooth operation of processes, reducing downtime and maintenance costs.

silo filter cartridge

Applications of Silo Filter Cartridges

Silo filter cartridges are widely utilized across various sectors, including

1. Agriculture In agricultural applications, silo filter cartridges are often used to manage the storage of grains and fertilizers. Contaminants such as dust and pests can be detrimental to crop quality. Using these filters helps protect agricultural products from potential spoilage.

2. Food Industry In the food industry, where hygiene and safety are paramount, silo filter cartridges are crucial for ensuring that materials such as flour, sugar, and grains remain uncontaminated during storage and transport.

3. Pharmaceuticals The pharmaceutical industry requires stringent adherence to cleanliness standards. Silo filter cartridges are employed to ensure that the raw materials and finished products are free from impurities, thus complying with industry regulations.

4. Construction Materials In construction, materials such as cement and gypsum are often stored in silos. Here, silo filter cartridges serve to prevent dust emissions, protecting workers' health and maintaining a clean site.

Conclusion

In summary, silo filter cartridges are an indispensable component in various industries that rely on bulk storage systems. Their ability to filter out contaminants not only protects the environment but also ensures product integrity and operational efficiency. As industries continue to evolve and environmental regulations become more stringent, the demand for effective filtration solutions like silo filter cartridges is expected to grow. Investing in high-quality filtration systems is essential for companies aiming to enhance their sustainability practices while ensuring compliance and product safety.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: