Tel:

+8615930870079

Tel:

+8615930870079

Dhj . 11, 2024 12:36 Back to list

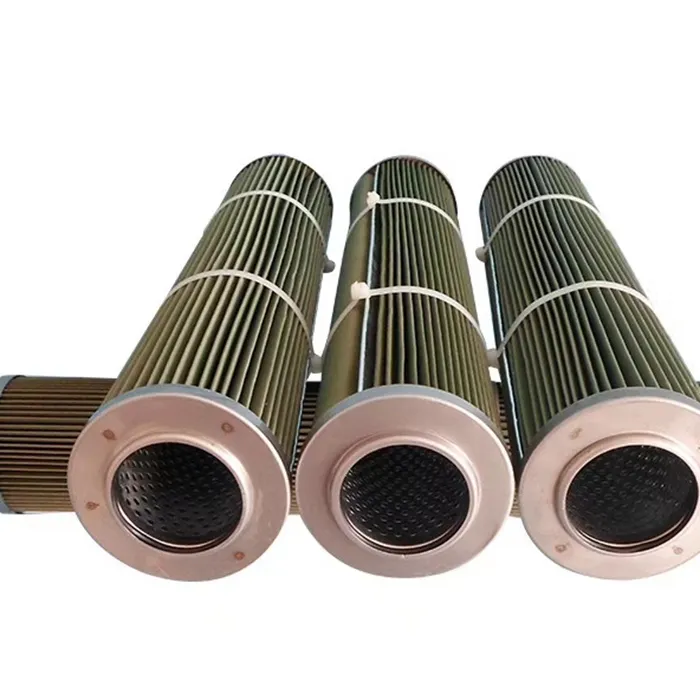

gas turbine filter

Gas Turbine Filters Essential Components for Optimal Performance

Gas turbines are a vital technology powering various industries, including aviation, power generation, and marine applications. These machines convert the chemical energy stored in fuel into mechanical energy, ultimately generating electricity or thrust. However, to ensure their efficient operation, gas turbines require effective filtration systems. This is where gas turbine filters come into play, serving as crucial components in maintaining the performance and longevity of gas turbines.

Understanding the Functionality of Gas Turbine Filters

Gas turbines operate in environments where they are exposed to various contaminants, such as dust, dirt, and other particulate matter. These contaminants can lead to significant issues, including reduced efficiency, increased maintenance costs, and even catastrophic failure if not adequately addressed. Gas turbine filters are designed to capture these harmful particles before they enter the turbine system, ensuring clean airflow and optimal operation.

The primary function of a gas turbine filter is to remove particulate matter from the incoming air. This is accomplished through a combination of mechanical and electrostatic filtration methods. Mechanical filters, such as those made from fiberglass or synthetic materials, trap particles based on size and mass. Meanwhile, electrostatic filters use charged elements to attract and capture smaller particles that would otherwise pass through mechanical filters.

Types of Gas Turbine Filters

There are several types of filters used in gas turbines, each suited for specific applications and environments

1. Pre-filters These are the first line of defense, designed to capture larger particles and prolong the life of subsequent filters. They are essential in environments with high dust levels and can significantly enhance filtration efficiency.

2. Primary Filters These filters provide the main filtration for the gas turbine. They are typically rated according to their efficiency at capturing particles of various sizes. High-efficiency filters are critical in applications where turbine performance is paramount.

gas turbine filter

3. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to capture at least 99.97% of particles as small as 0.3 microns. They are used in applications that require extremely clean air, such as in hospitals and data centers.

4. Activated Carbon Filters In scenarios where chemical contaminants or odors are a concern, activated carbon filters can be employed. These filters adsorb gaseous pollutants, ensuring that the air entering the turbine is as clean as possible.

The Importance of Maintaining Gas Turbine Filters

Routine maintenance of gas turbine filters is critical to ensure their efficacy. Clogged or dirty filters can lead to reduced airflow, causing the turbine to work harder, which can result in increased energy consumption and wear. Regular inspection and replacement of filters can mitigate these risks, helping to maintain optimal performance and extend the lifespan of the turbine.

In many cases, the choice of filter will depend on the operational environment of the gas turbine. For instance, turbines operating in coastal regions may require filters with higher salt resistance, while those located in industrial areas may need enhanced particulate filtration capabilities. It’s important for facility managers to understand the specific requirements of their equipment and select filters accordingly.

Environmental Considerations and Advancements

With increasing attention on environmental issues, manufacturers are exploring advanced filtration technologies that not only enhance turbine performance but also reduce ecological impact. Innovative materials and designs are being developed to improve filtration efficiency while minimizing waste. Additionally, some companies are investigating self-cleaning filter technologies that reduce maintenance downtime and ensure consistent airflow without manual intervention.

Conclusion

In summary, gas turbine filters are indispensable components that play a vital role in ensuring efficient and reliable turbine operation. By capturing harmful particulate matter and preventing damage, these filters contribute to the overall performance and longevity of gas turbines. With advancements in technology and increased emphasis on maintenance, the future of gas turbine filtration looks promising—ensuring cleaner, more efficient energy production for generations to come.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: