Tel:

+8618931101301

Tel:

+8618931101301

Dhj . 22, 2024 18:44 Back to list

Improving Air Intake Filter Efficiency for Gas Turbine Performance and Longevity

The Importance of Air Intake Filters in Gas Turbine Operation

Gas turbines are an essential component in various industries, providing power generation and mechanical energy for a wide range of applications. One of the critical systems in a gas turbine setup is the air intake system, which relies heavily on air intake filters. These filters play a vital role in ensuring the efficiency, reliability, and longevity of gas turbine operations. In this article, we will explore the significance of air intake filters, their types, and their impact on gas turbine performance.

The Role of Air Intake Filters

Air intake filters are designed to remove particulate matter, dust, and pollutants from the air before it enters the gas turbine. Clean air is crucial for optimal turbine performance, as contaminants can lead to various issues, including efficiency loss, increased maintenance needs, and potential damage to turbine components. The primary function of these filters is to ensure that the air entering the combustion process is as clean as possible, thereby safeguarding the internal systems of the turbine.

Types of Air Intake Filters

There are several types of air intake filters used in gas turbines, each designed to meet specific requirements based on operational conditions and environmental factors. The most common types include

1. Panel Filters These are typically made of synthetic or fiberglass media and are used for pre-cleaning air. Panel filters are designed to capture larger particles and extend the life of more expensive downstream filters.

.

2. V-Bank Filters V-bank filters have a unique design that increases filtration surface area while maintaining a compact size. They are highly efficient in trapping small-sized particles and are often used in more demanding environments.

3. Coalescing Filters These filters are designed to remove both particulate matter and liquid contaminants, such as water and oil. They are particularly important in humid or industrial environments where additional liquid contaminants can be present in the air.

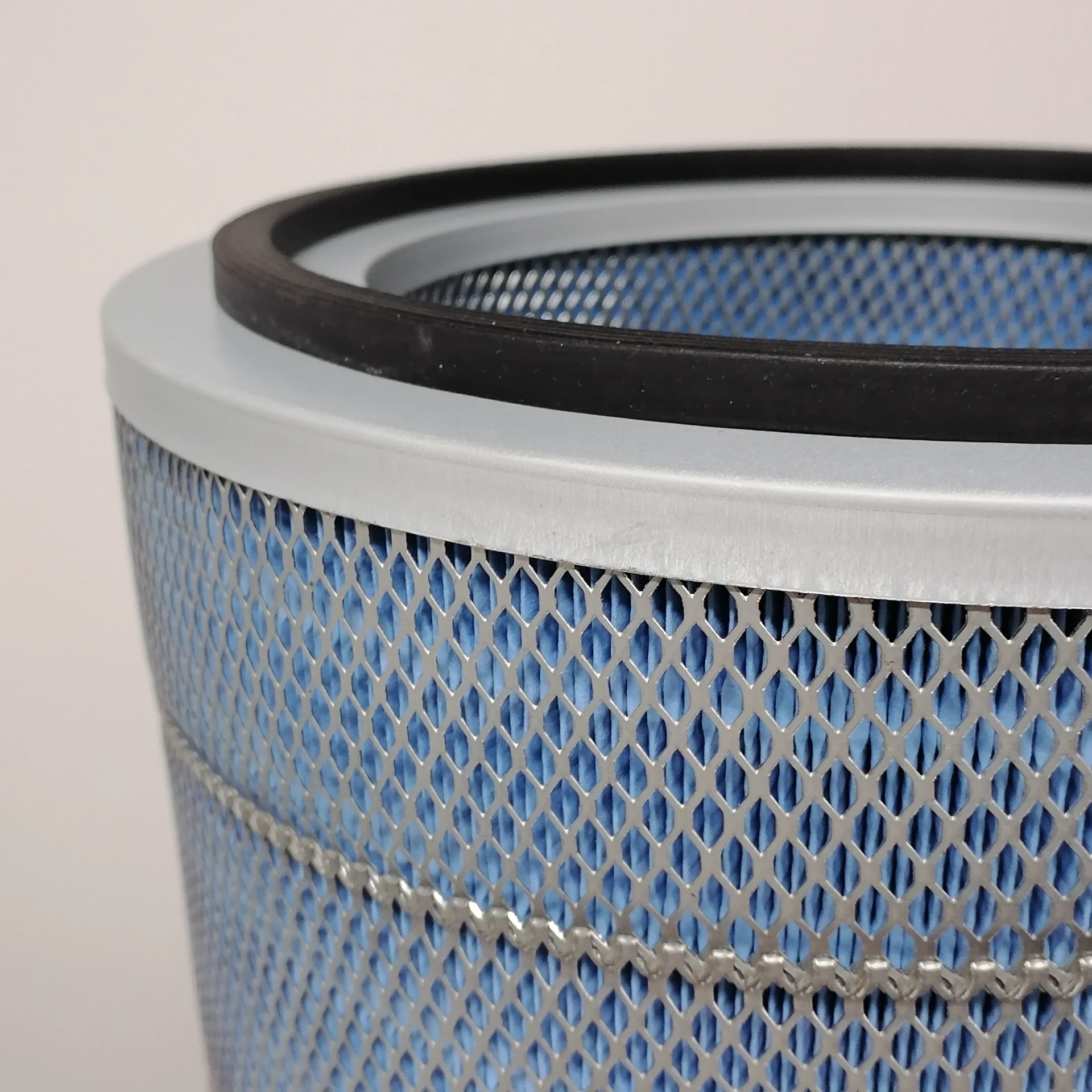

gas turbine air intake filter

4. High-Efficiency Particulate Air (HEPA) Filters HEPA filters are among the highest-performing filters for air purification, capturing up to 99.97% of particles as small as 0.3 microns. While more costly and harder to maintain, HEPA filters are crucial in environments where air quality is paramount.

Impact on Gas Turbine Performance

The quality of air entering a gas turbine has a direct impact on its efficiency and operational reliability. When filters are not properly maintained or are clogged with contaminants, they can restrict airflow, leading to reduced turbine performance. This restriction forces the turbine to work harder, potentially resulting in increased fuel consumption and emissions. In the long run, poor air quality can also lead to more frequent and intensive maintenance, raising operational costs.

Moreover, unfiltered or poorly filtered air can introduce corrosive elements into the turbine, which can lead to premature wear on components such as blades and combustion chambers. This not only reduces the lifespan of the turbine but can also compromise safety.

Maintenance and Best Practices

To ensure optimal gas turbine performance, regular maintenance of air intake filters is crucial. Operators must establish a filter inspection and replacement schedule based on the operating environment. For instance, in dusty or industrial settings, more frequent changes may be necessary to prevent performance degradation.

Additionally, the use of advanced monitoring technologies can enhance maintenance practices. Sensors can be installed to monitor pressure drop across filters, providing real-time data on the condition of the filters and signaling when replacements are due.

Conclusion

Air intake filters are a crucial component of gas turbine operation, ensuring that the air entering the combustion chamber is clean and uncontaminated. By utilizing the appropriate type of filter and adhering to a diligent maintenance schedule, operators can enhance the efficiency, reliability, and longevity of their gas turbines. Investing in quality air intake filtration systems not only improves turbine performance but also contributes to overall operational success in various industrial applications.

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

Email:

Email: