Tel:

+8615930870079

Tel:

+8615930870079

Nën . 22, 2024 15:46 Back to list

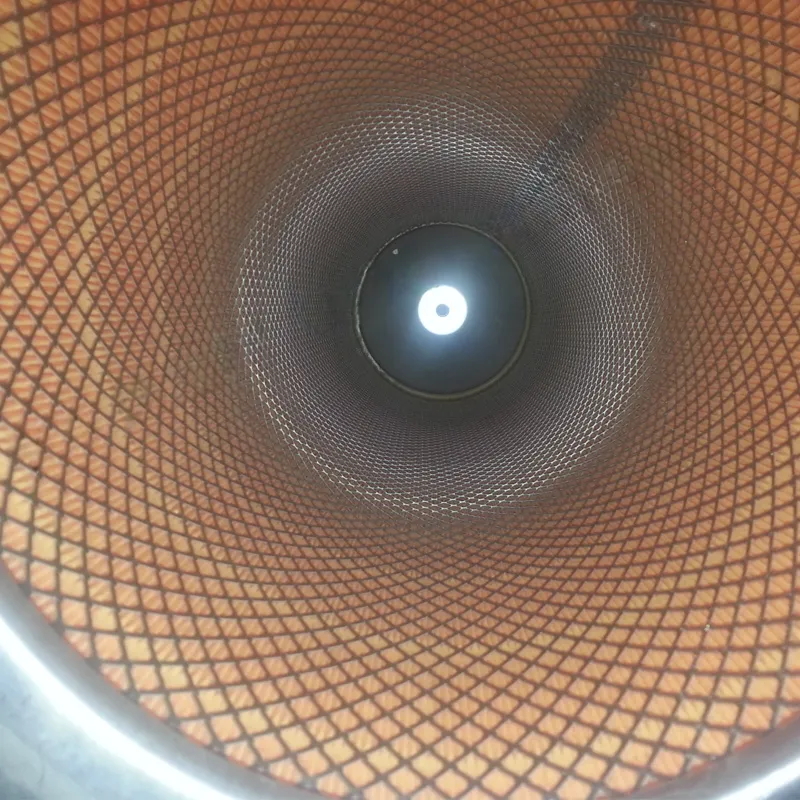

gas turbine air intake filter

Gas Turbine Air Intake Filters Ensuring Optimal Performance and Longevity

Gas turbines play a crucial role in modern power generation and aviation, providing efficient energy conversion and propulsion. One of the most critical components affecting the performance of gas turbines is the air intake system, particularly the air intake filters. These filters are essential for ensuring that the components of the turbine operate under optimal conditions by delivering clean air necessary for the combustion process.

The Importance of Air Intake Filters

Air intake filters serve as the first line of defense against contaminants such as dust, dirt, and allergens. Without effective filtration, these particles can infiltrate the gas turbine, leading to several detrimental effects. Contaminants can cause erosion, corrosion, and fouling of the turbine blades and other components, resulting in decreased efficiency and increased maintenance costs. Moreover, the accumulation of dirt and debris can impair airflow, further compromising the operational efficiency of the gas turbine and its overall output.

Types of Filters

There are various types of air intake filters suitable for gas turbines, each designed to tackle specific environmental challenges. Pleated filters, for instance, offer a large surface area for capturing particles and extend the interval between necessary replacements. Foam filters, on the other hand, are excellent for capturing larger debris but may not be as effective for smaller particles. HEPA (High-Efficiency Particulate Air) filters provide superior filtration capabilities, capable of trapping 99.97% of particles as small as 0.3 microns, making them ideal for environments with high levels of airborne pollutants.

gas turbine air intake filter

Maintenance and Performance

The performance of air intake filters is closely linked to the maintenance practices employed. Regular inspections and replacements are necessary to ensure filters operate at peak efficiency. Clogged or dirty filters can greatly reduce airflow, leading to a decrease in turbine performance and an increase in fuel consumption. Operators should adhere to a defined maintenance schedule and utilize pressure differential measurements to determine when filters need replacement.

In addition to routine maintenance, advancements in technology are increasingly being integrated into air intake systems. Some modern filters are equipped with sensors that monitor filter conditions in real-time. This technology allows for better management of filter lifecycle and replacement timing, leading to improved overall turbine performance.

Conclusion

In conclusion, gas turbine air intake filters play a vital role in maintaining the efficiency, performance, and longevity of gas turbines. By effectively removing contaminants from the air, these filters protect turbine components from damage and ensure optimal operation. Operators must prioritize regular maintenance and consider adopting new technologies to monitor filter conditions. As industries strive for greater efficiency and sustainability, investing in high-quality air intake filters will continue to be a fundamental aspect of gas turbine operation, contributing to cleaner energy generation and enhanced performance in various applications.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: