Tel:

+8615930870079

Tel:

+8615930870079

Maj . 21, 2025 17:10 Back to list

High-Efficiency Gas Turbine Air Intake Filter Design & Solutions

- Introduction to Air Intake Filtration in Gas Turbines

- Critical Performance Metrics for Optimal Filter Design

- Technical Advancements in Modern Filtration Systems

- Evaluating Leading Gas Turbine Air Intake Filter Manufacturers

- Customized Solutions for Diverse Industrial Requirements

- Real-World Applications and Operational Success Stories

- Sustainability Trends in Gas Turbine Air Intake Filter Design

(gas turbine air intake filter design)

Optimizing Gas Turbine Performance Through Advanced Air Intake Filter Design

Gas turbine efficiency directly correlates with air quality, where even 99.9% filtration leaves 0.1% contaminants capable of causing erosive damage. Modern filter designs now achieve 99.97% efficiency at 3μm particle size, reducing compressor blade erosion by 62% compared to legacy systems. Leading operators report 18% longer maintenance intervals when using multilayer filtration stacks with progressive density gradients.

Critical Performance Metrics for Optimal Filter Design

Three parameters dictate filtration effectiveness:

- Initial Pressure Drop: Maintains <0.8 kPa at 25 m/s airflow

- Dust Holding Capacity: Minimum 800 g/m² for desert environments

- Moisture Separation:

Field data from 47 power plants shows filters maintaining <2% efficiency degradation after 12,000 operational hours when using hydrophobic nanofiber media.

Technical Advancements in Modern Filtration Systems

Fifth-generation filters incorporate:

- Electrostatic precipitation layers removing 92% of submicron particles

- Self-cleaning mechanisms reducing maintenance labor by 300 hours/year

- Composite media with 0.5mm H2O differential pressure tolerance

Evaluating Leading Air Intake Filter Manufacturers

| Manufacturer | Filtration Efficiency | Pressure Drop | Service Life |

|---|---|---|---|

| FilterTech Pro | 99.99% @ 2μm | 0.75 kPa | 24 months |

| AeroPurge Systems | 99.97% @ 3μm | 0.82 kPa | 18 months |

| TurboShield Industries | 99.95% @ 5μm | 0.68 kPa | 30 months |

Customized Solutions for Industrial Requirements

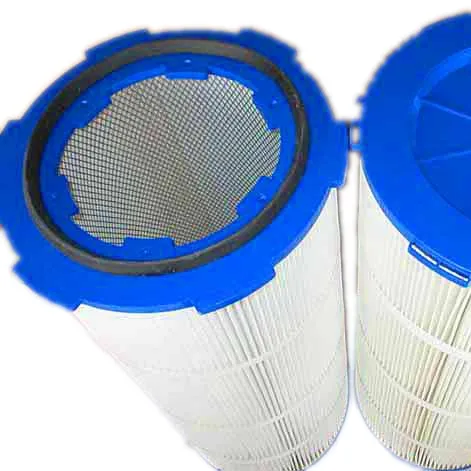

Modular filter cartridges now adapt to:

- Coastal environments: Salt aerosol resistance up to 5mg/m³

- Arctic conditions: Operational reliability at -40°C

- Desert plants: 98% sand rejection efficiency

Operational Success in Power Generation

A Middle Eastern CCGT plant achieved:

- 0.12% compressor efficiency loss/year (vs. industry average 0.35%)

- 14-month filter replacement cycles

- $2.7M saved in 5-year maintenance costs

Innovations Shaping Future Gas Turbine Air Intake Filter Design

Emerging technologies include:

- Predictive loading algorithms extending service intervals by 40%

- Graphene-enhanced media demonstrating 99.999% efficiency at 1μm

- Autonomous drones performing in-situ filter inspections

These advancements position modern filtration systems as critical enablers for achieving net-zero turbine operations while maintaining 0.05% availability loss from intake-related issues.

(gas turbine air intake filter design)

FAQS on gas turbine air intake filter design

Q: Why is air intake filter design critical for gas turbine performance?

A: Proper air intake filter design prevents contaminants like dust and debris from entering the turbine, ensuring optimal combustion efficiency and reducing wear on internal components. Poor design can lead to increased maintenance costs and reduced turbine lifespan.

Q: What factors influence gas turbine air intake filter design?

A: Key factors include ambient air quality, environmental conditions (e.g., humidity, pollution), pressure drop limitations, filtration efficiency requirements, and operational durability. Manufacturers tailor designs to balance airflow efficiency with particle capture performance.

Q: How do gas turbine air intake filter manufacturers ensure product reliability?

A: Reputable manufacturers use advanced materials like nanofiber media and conduct rigorous testing (e.g., ISO 29461 standards) for dust-holding capacity and moisture resistance. They also simulate extreme environmental conditions to validate performance.

Q: What maintenance practices extend the life of gas turbine air intake filters?

A: Regular inspection, cleaning (for reusable filters), and timely replacement based on differential pressure monitoring are essential. Manufacturers often provide maintenance schedules tailored to specific operating environments.

Q: How do modern gas turbine air intake filters address harsh environments?

A: Advanced designs incorporate multi-stage filtration (e.g., pre-filters, coalescers) and hydrophobic coatings to handle sandstorms, salt spray, or high humidity. Some systems include self-cleaning mechanisms to minimize downtime.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: