Tel:

+8618931101301

Tel:

+8618931101301

Dhj . 09, 2024 22:34 Back to list

Pleated Filters for Efficient Dust Collection in Industrial Applications

Understanding Dust Collector Pleated Filters Enhancing Air Quality and Operational Efficiency

Dust collector pleated filters are an essential component in various industrial applications, designed to improve air quality and enhance operational efficiency. These filters play a critical role in removing particulate matter from the air, preventing dust and pollutants from being released into the environment. As industries continue to prioritize sustainability and worker safety, pleated filters have emerged as a popular choice due to their superior performance and longevity.

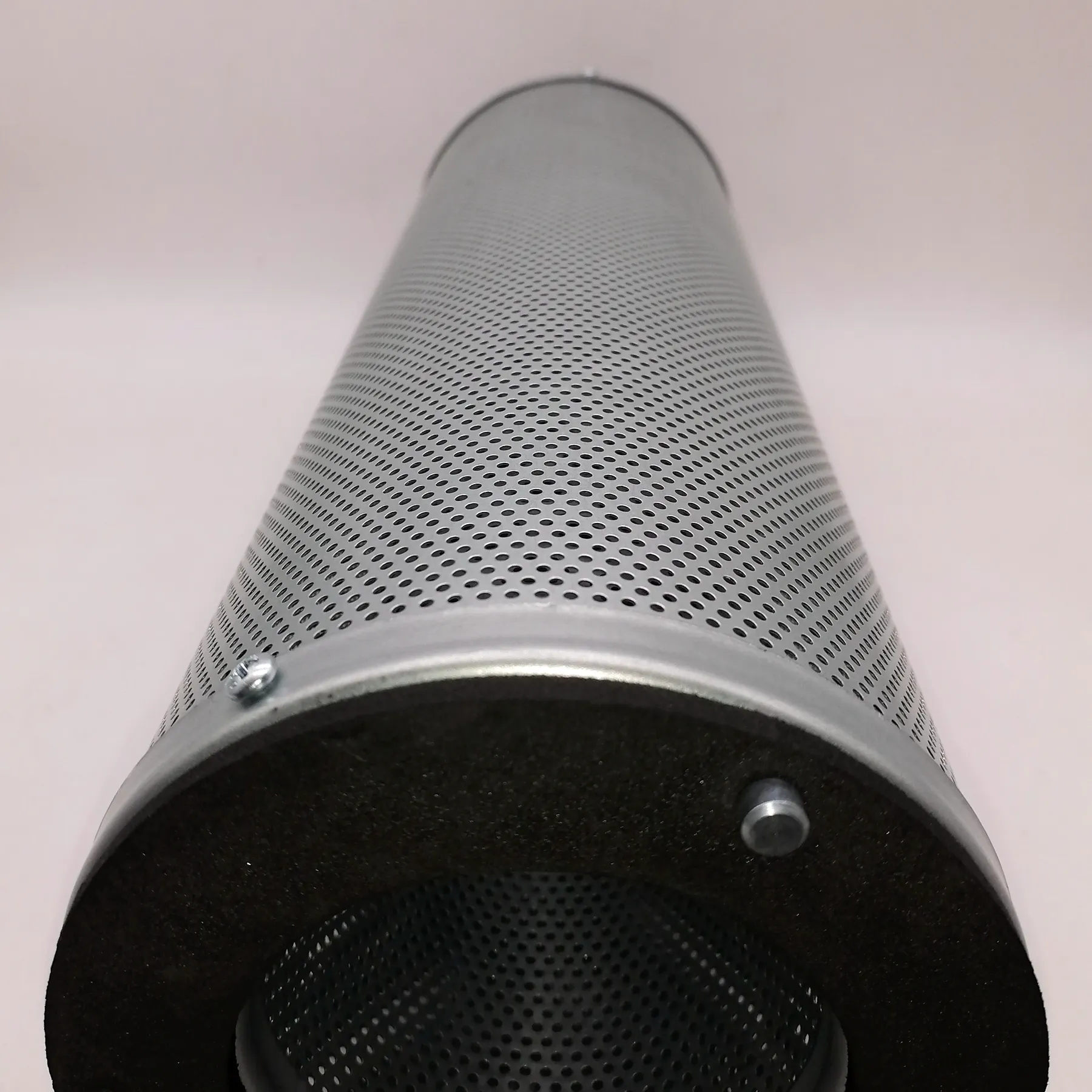

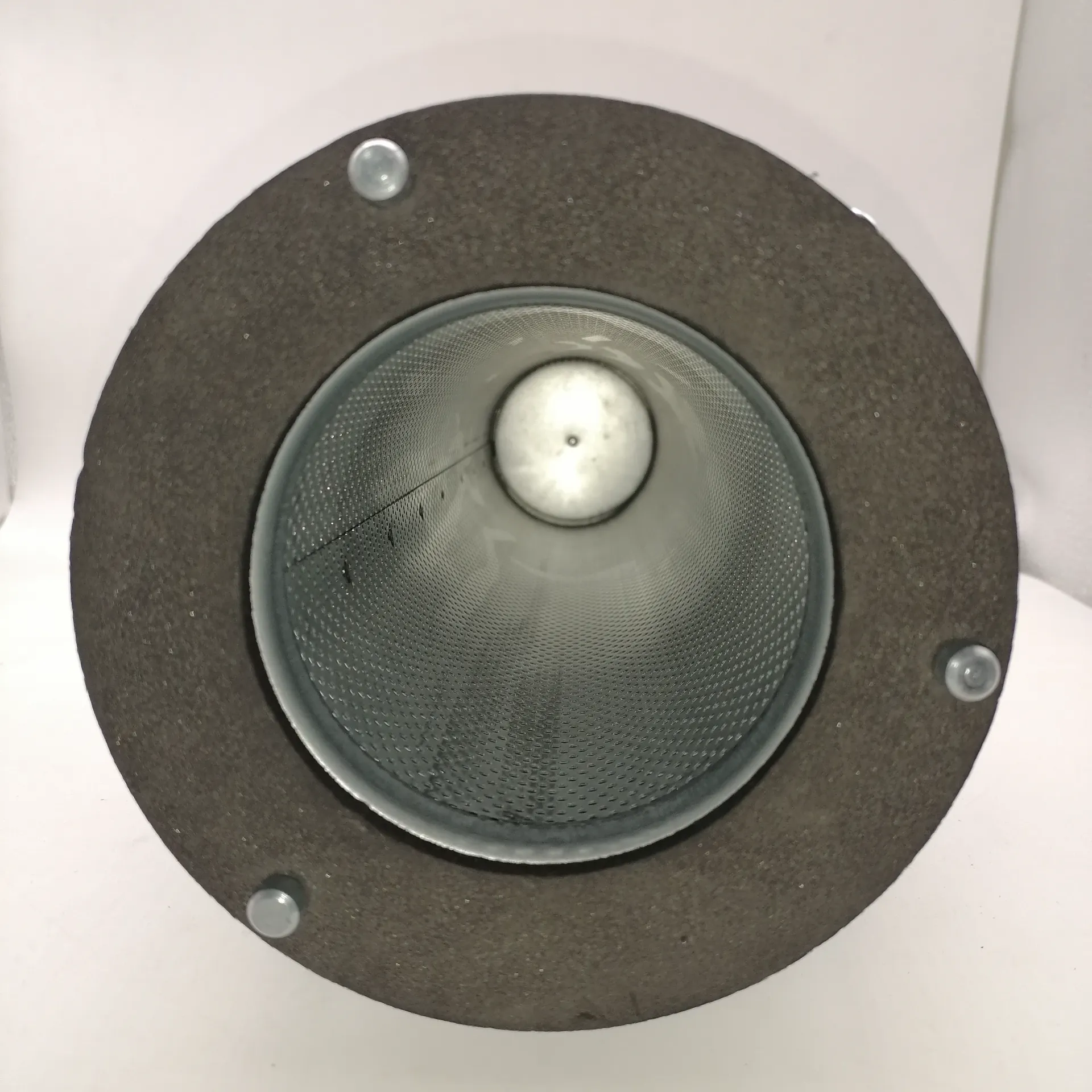

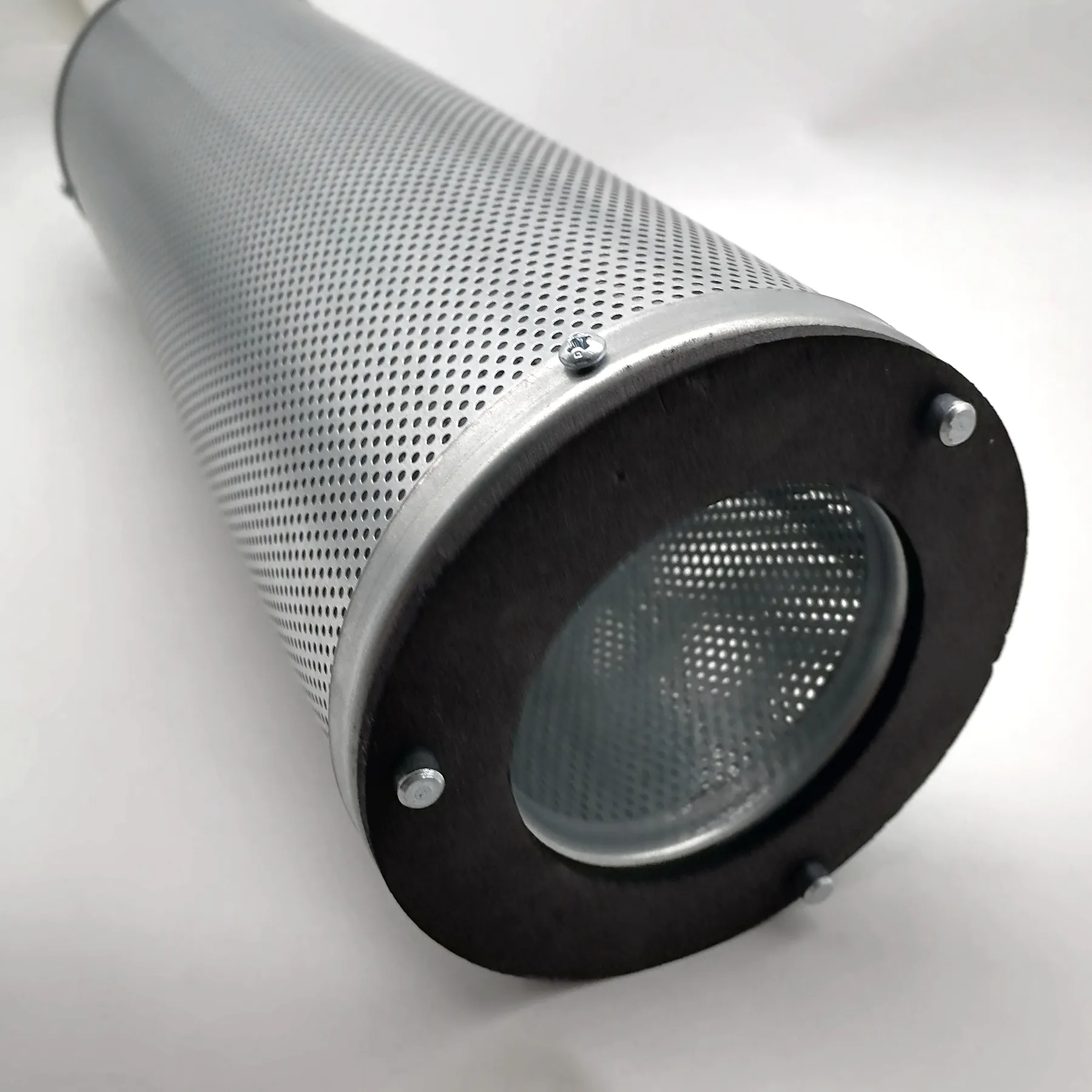

The Structure and Function of Pleated Filters

Pleated filters are characterized by their unique design, which features multiple folds or pleats. This design significantly increases the surface area of the filter while minimizing the space it occupies. The increased surface area allows for greater dust capture efficiency, as there is more material available to trap particulate matter as air flows through the filter. This design contrasts with traditional flat filters, which can become quickly clogged and require more frequent replacements.

When air containing dust and other contaminants passes through a pleated filter, the particles are trapped within the fiber matrix. The pleats enable the filter to maintain high airflow rates while simultaneously providing effective filtration. As a result, pleated filters can handle higher dust loads, reducing the frequency of maintenance and the associated downtime.

Advantages of Pleated Filters

1. Higher Efficiency Pleated filters generally have a higher filtration efficiency compared to traditional filters. They can capture smaller particles, including allergens, mold spores, and other harmful pollutants, which is particularly important in industries where air quality is critical.

2. Longer Lifespan Due to their superior design, pleated filters tend to have a longer operational lifespan. They can endure heavier dust loads before becoming clogged, translating to lower replacement costs over time and less impact on production schedules.

3. Reduced Energy Consumption With reduced resistance to airflow, pleated filters often lead to lower energy consumption in dust collection systems. This is particularly beneficial for businesses looking to reduce their operational costs and carbon footprint.

dust collector pleated filter

4. Versatile Applications Pleated filters can be used in a variety of settings, from manufacturing plants and woodworking shops to food processing and pharmaceuticals. Their versatility makes them an ideal choice for any industry that generates airborne dust or contaminants.

Maintenance and Care

While pleated filters are designed to last longer, regular maintenance is still essential to ensure optimal performance. Most manufacturers recommend periodic inspections to check for signs of damage or significant dust buildup. Cleaning or replacing filters according to the manufacturer's specifications can prevent unnecessary strain on dust collection equipment and maintain air quality standards.

Environmental Impact

The importance of efficient air filtration systems cannot be overstated, especially in the context of environmental sustainability. The use of pleated filters contributes to cleaner air, which is vital for both human health and the environment. By effectively capturing pollutants, these filters help industries comply with environmental regulations and reduce their contributions to air pollution.

In addition, the longevity and efficiency of pleated filters can lead to less waste generated from discarded filters and lower energy usage, supporting sustainability efforts. Companies can gain positive recognition for their commitment to eco-friendly practices by utilizing these advanced filtration systems.

Conclusion

Dust collector pleated filters are an invaluable investment for various industrial applications. Their superior design, efficiency, and longevity make them a preferred choice for businesses seeking to enhance air quality, reduce maintenance costs, and contribute to environmental sustainability. As industries continue to evolve and prioritize air quality standards, pleated filters will play a pivotal role in maintaining cleaner, safer work environments. Embracing such technology not only benefits businesses but also fosters a healthier planet for future generations.

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

Email:

Email: