ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Shk . 01, 2025 03:03 Back to list

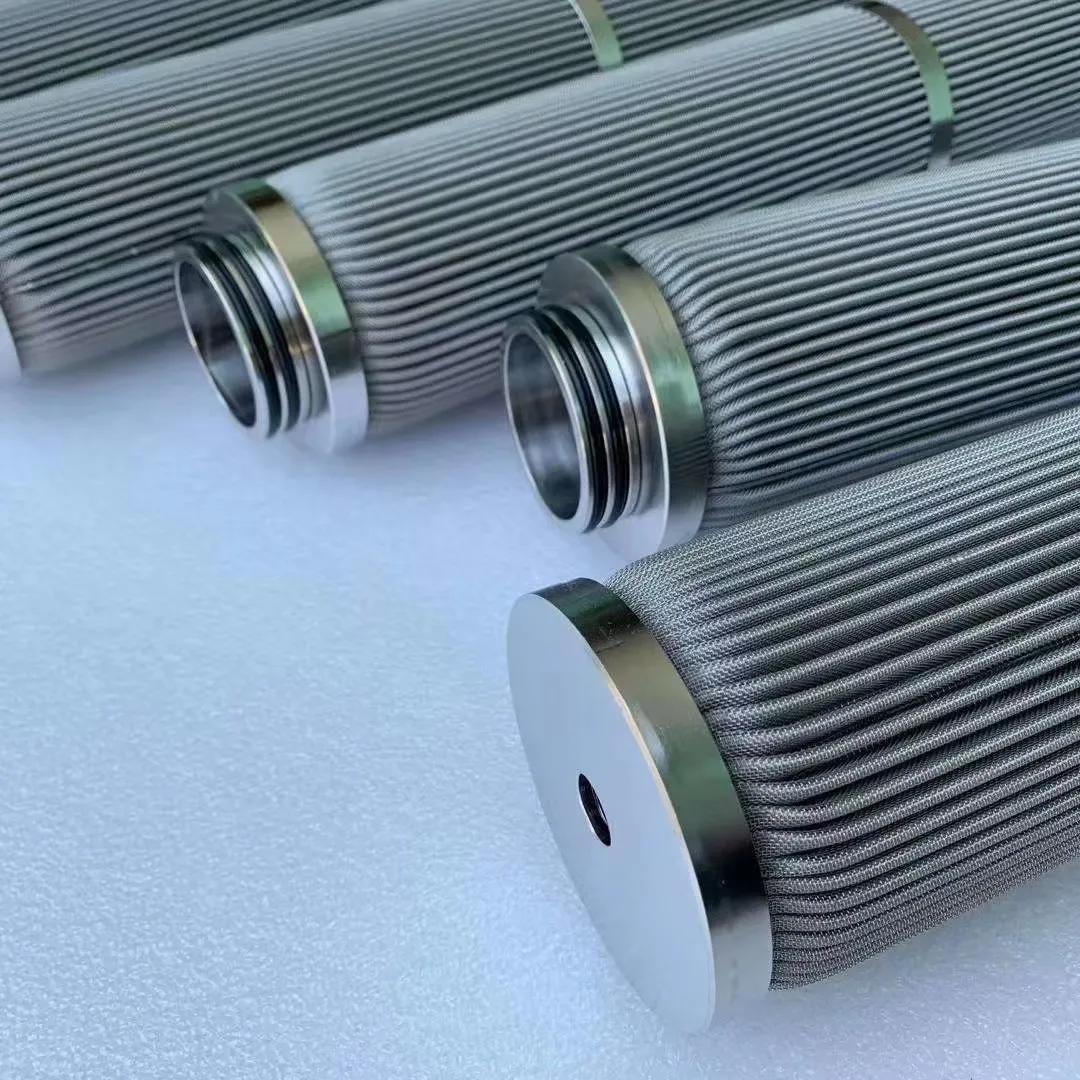

pleated filter cartridge dust collector

Dust collector pleated filters are an essential component in ensuring the efficiency and longevity of industrial dust collection systems. Their design and material choices can significantly impact the performance of these systems, affecting everything from air quality to operational costs. This article delves into the benefits and considerations of using pleated filters within dust collectors, multiplying their potential through the lens of real-world experiences, expert insights, and authoritative data.

Moreover, from a sustainability perspective, pleated filters contribute to reducing environmental impact. By lasting longer than their non-pleated counterparts, they generate less waste. Additionally, many manufacturers have started using recyclable materials in filter production, further cementing their role in responsible industry practices. A study from the National Institute for Industrial Environment and Risks highlights that employing longer-lasting filters not only enhances cost-efficiency but also aligns with the sustainable practices crucial for modern industries striving for carbon neutrality. From a practical standpoint, operators should ensure that their dust collection systems are compatible with pleated filters. Regular testing and monitoring of the systems' airflow and pressure differentials can indicate whether these filters are optimizing performance or require adjustments. Real-life case studies reveal that facilities conducting routine checks often experience a marked improvement in air quality and equipment efficiency when pleated filters are involved. Trustworthiness in the use of pleated filters is further reinforced by testimonials and case studies from industry leaders who have documented improvements in workplace safety and operational efficiency post-installation. Companies have reported not only compliance with safety regulations but also an enhancement in worker morale, knowing they are operating in a cleaner, safer environment. In conclusion, the adoption of pleated filters in dust collection systems is a decision that draws from a blend of expertise, authority, and trust. Their efficient design, compliance with industry standards, focus on sustainability, and positive real-world performance reviews make them a compelling choice for industries looking to upgrade their filtration systems. Integrating these innovative filters can significantly enhance air quality, reduce costs, and support sustainable practices, all of which are essential facets in the modern industrial landscape.

Moreover, from a sustainability perspective, pleated filters contribute to reducing environmental impact. By lasting longer than their non-pleated counterparts, they generate less waste. Additionally, many manufacturers have started using recyclable materials in filter production, further cementing their role in responsible industry practices. A study from the National Institute for Industrial Environment and Risks highlights that employing longer-lasting filters not only enhances cost-efficiency but also aligns with the sustainable practices crucial for modern industries striving for carbon neutrality. From a practical standpoint, operators should ensure that their dust collection systems are compatible with pleated filters. Regular testing and monitoring of the systems' airflow and pressure differentials can indicate whether these filters are optimizing performance or require adjustments. Real-life case studies reveal that facilities conducting routine checks often experience a marked improvement in air quality and equipment efficiency when pleated filters are involved. Trustworthiness in the use of pleated filters is further reinforced by testimonials and case studies from industry leaders who have documented improvements in workplace safety and operational efficiency post-installation. Companies have reported not only compliance with safety regulations but also an enhancement in worker morale, knowing they are operating in a cleaner, safer environment. In conclusion, the adoption of pleated filters in dust collection systems is a decision that draws from a blend of expertise, authority, and trust. Their efficient design, compliance with industry standards, focus on sustainability, and positive real-world performance reviews make them a compelling choice for industries looking to upgrade their filtration systems. Integrating these innovative filters can significantly enhance air quality, reduce costs, and support sustainable practices, all of which are essential facets in the modern industrial landscape.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: