Tel:

+8615930870079

Tel:

+8615930870079

Tet . 13, 2024 05:28 Back to list

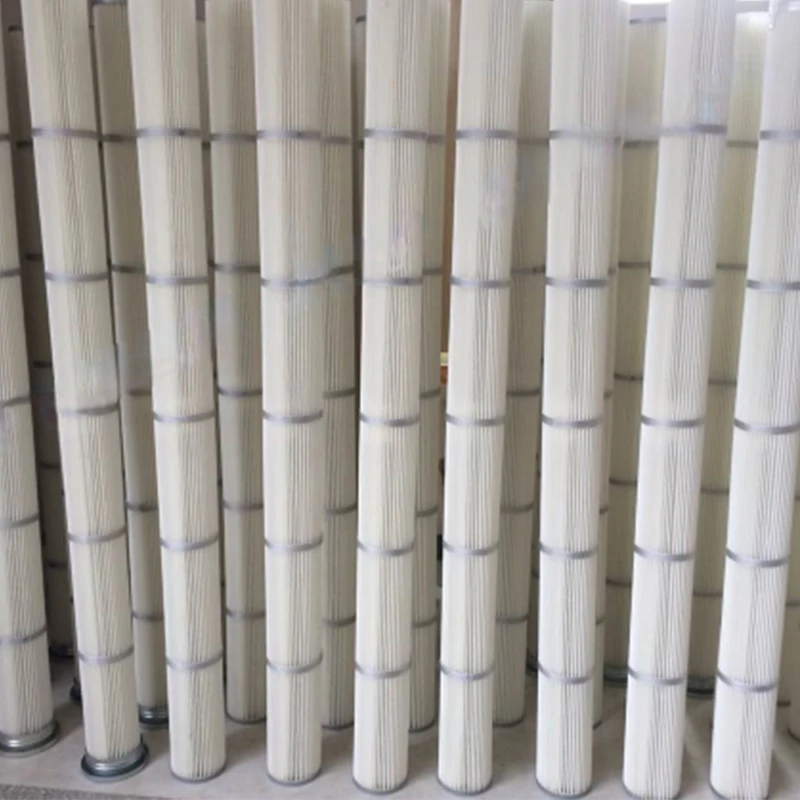

Effective Cartridge Filter Vacuum Solutions for Optimal Filtration and Performance

Understanding Cartridge Filter Vacuum Systems

In the realm of industrial filtration, cartridge filter vacuum systems have emerged as a highly efficient and effective solution for various applications. Combining the principles of filtration and vacuum technology, these systems are designed to remove contaminants from air or liquid, ensuring a cleaner environment and enhancing operational efficiency. This article aims to explore the functionalities, advantages, and applications of cartridge filter vacuum systems.

What are Cartridge Filter Vacuum Systems?

A cartridge filter vacuum system primarily consists of a vacuum pump, a cartridge filter, and a collection bin. The system operates on the principle of creating a negative pressure that draws in air or liquid containing particulates. As the contaminated fluid passes through the cartridge filter, solid particles are trapped, and the filtered medium is expelled back into the system or sent for further processing. The cartridge filter itself is usually made from materials such as polyester, polypropylene, or nylon, selected based on the specific application and type of contaminants involved.

The Importance of Filtration

Filtration is critical in many industries, including food and beverage, pharmaceuticals, and manufacturing, where particulate contamination can lead to product defects, compliance issues, and potential health risks. By incorporating cartridge filter vacuum systems, businesses can significantly improve their product quality and maintain regulatory compliance. For instance, in the pharmaceutical industry, ensuring the purity of liquids is essential, and these systems can help achieve that by filtering out unwanted substances effectively.

Advantages of Cartridge Filter Vacuum Systems

1. Efficiency One of the most significant advantages of cartridge filter vacuum systems is their high filtration efficiency. These systems can capture particles as small as a few microns, ensuring that the end product is of high quality.

2. Low Maintenance Unlike traditional filtration methods, cartridge filters are relatively low maintenance. They can be easily replaced, and many systems are designed for quick and straightforward filter change-outs, minimizing downtime and labor costs.

3. Versatility Cartridge filter vacuum systems are versatile and can be adapted for various applications, whether for filtering air, liquids, or both. This flexibility makes them suitable for diverse industries, including automotive, chemical, and food processing.

cartridge filter vacuum

4. Compact Design Due to their design, cartridge filter vacuum systems can save valuable floor space compared to bulkier filtration systems. Their compact nature allows for easier integration into existing production lines or workspaces.

5. Environmental Impact By effectively capturing particulates and preventing them from entering the environment, these filtration systems significantly reduce the pollution generated by industrial processes. This aspect is particularly important given the increasing regulations regarding environmental sustainability.

Applications of Cartridge Filter Vacuum Systems

Cartridge filter vacuum systems find applications in various sectors

- Food and Beverage Used for filtering juices, oils, and beverages to ensure product purity and enhance shelf life.

- Pharmaceuticals Critical for maintaining sterile environments and ensuring the purity of liquid medicines and compounds.

- Manufacturing Employed in applications requiring the removal of metal shavings, dust, and other debris from production processes, ensuring equipment longevity and operational efficiency.

- Industrial Cleaning Utilized for cleaning up spills and managing waste in industrial settings, helping maintain workplace safety and hygiene.

Conclusion

In conclusion, cartridge filter vacuum systems play an essential role in modern filtration technologies. Their efficiency, low maintenance needs, and versatility make them invaluable to various industries seeking to enhance productivity and ensure product quality. By investing in these systems, companies can not only comply with industry standards but also contribute to environmental sustainability, ensuring cleaner air and water for future generations. Understanding and implementing cartridge filter vacuum technology is a step toward a more efficient and cleaner industrial process.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: