Tel:

+8615930870079

Tel:

+8615930870079

Qer . 09, 2025 21:12 Back to list

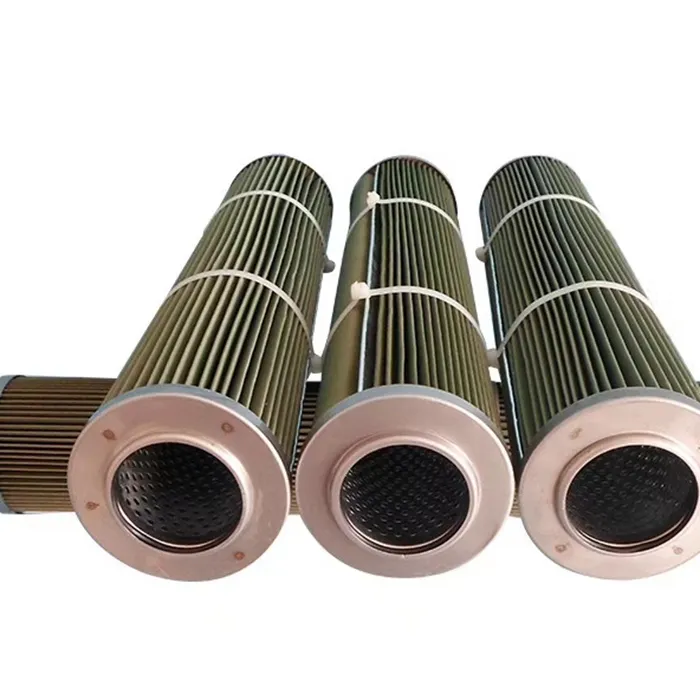

Premium Activated Carbon Cartridge - Superior Odor Removal & Air Purification

- Introduction to Activated Carbon Filtration Technology

- Performance Metrics Impacting Industrial Applications

- Breakdown of Technical Advantages in Modern Designs

- Comparative Analysis of Leading Manufacturers in Europe

- Customization Parameters for Industry-Specific Requirements

- Implementation Case Studies Across Multiple Sectors

- Future Development Trends in Carbon-Based Filtration

(cartouche de charbon actif)

The Essential Role of Cartouche de Charbon Actif in Industrial Purification

Activated carbon filter cartridges represent critical filtration components across numerous industries, leveraging adsorption mechanisms to remove contaminants at molecular level. These specialized cartridges contain processed carbon with expanded surface area, typically ranging from 500-1500 m²/g. Industries utilizing cartouche de filtre à air au charbon actif experience 40-95% contaminant reduction rates depending on application parameters.

Physical adsorption occurs through Van der Waals forces where contaminants bond to the carbon surface. The activated carbon's porous structure features micropores (under 2nm diameter), mesopores (2-50nm) and macropores (over 50nm), creating an extensive network for capturing volatile compounds. Environmental regulations increasingly mandate these solutions, with the EU mandating 85% VOC removal in manufacturing exhaust systems.

Selection criteria for élément filtrant au charbon actif include iodine number (measuring microporosity), hardness (abrasion resistance), ash content, and CTC adsorption capacity. Optimal configurations combine coconut shell carbon for small molecule capture with coal-based carbon for larger contaminants, creating hybrid filtration systems with broader application ranges.

Performance Metrics Impacting Industrial Applications

Operational efficiency correlates directly with measurable performance indicators. Adsorption capacity varies significantly by cartridge specifications:

Capacity testing under ASTM standards reveals:

- VOC adsorption rates from 0.3 to 0.6 g/cm³ carbon volume

- Water vapor adsorption between 4-22% weight increase

- Pressure drop maintained under 1.5 inches water column at 100 CFM flow

Service lifespan depends critically on contaminant concentrations with medical facilities achieving 18-24 month service intervals versus manufacturing plants requiring quarterly replacements at high particulate loads. Particle retention efficiency averages 98.7% for particles above 0.3μm when combining activated carbon with HEPA pre-filters.

Breakdown of Technical Advantages in Modern Designs

Contemporary cartouche de charbon actif

integrate multiple innovations boosting functional performance:

Structural improvements: Radial flow configurations reduce pressure drop by 30% compared to axial designs while increasing contact time. Dual-density packing combines coarse mesh carbon (2-3mm particle size) at peripheral zones with finer media (1-1.5mm) at core sections, optimizing flow distribution and adsorbent utilization.

Material science advancements: Manufacturers now impregnate activated carbon with specific chemical agents to enhance adsorption of challenging contaminants. Potassium permanganate impregnation boosts ethylene removal by 40% for produce storage, while phosphoric acid treatment enhances ammonia capture in waste processing facilities.

Modular integration capabilities: Standardized housing systems (ISO 29461 compliant) allow quick-change cartridge replacement in under 5 minutes, minimizing operational downtime. End cap designs incorporate silicone gaskets maintaining seal integrity at temperatures from -20°C to 80°C.

Comparative Analysis of Leading Manufacturers in Europe

Performance characteristics vary significantly across brands:

| Manufacturer | VOC Removal Rate | Max Pressure Rating | Service Life Index | Unit Cost (€) |

|---|---|---|---|---|

| Carbotech Solutions | 97.3% | 12 bar | 9.2 months | 245-380 |

| Purafil Europe | 95.1% | 8 bar | 7.8 months | 195-310 |

| KX Industries | 98.6% | 16 bar | 10.3 months | 310-495 |

| Lenntech Systems | 92.7% | 6 bar | 5.5 months | 145-235 |

Independent testing (2023) by EUROVENT confirms Carbotech delivers best cost-performance balance in pharmaceutical settings while KX Industries maintains advantage in high-pressure industrial processes. Service life measurements conducted at ISO Class 7 cleanrooms with constant 85% humidity.

Customization Parameters for Industry-Specific Requirements

Tailored cartouche de filtre à air au charbon actif configurations adapt to specialized purification needs:

Industrial ventilation: Oversized carbon beds (150-300mm depth) paired with aluminum mesh pre-filters target paint booth exhaust, achieving 7,500-15,000 hour service intervals before saturation. Pressure vessels rated for 150°C air streams incorporate ceramic bonding agents preventing carbon fragmentation.

Water purification: NSF-42 certified food-grade cartridges feature 0.5-5 micron carbon block construction removing chlorine while preserving mineral content. Backwashing capabilities maintain efficacy with turbidity levels up to 5 NTU without premature clogging.

Semiconductor manufacturing:

Custom engineering services typically require 6-8 weeks lead time with prototype validation conducted at accredited laboratories. Cost premiums for specialized configurations range from 30-200% over standard models depending on technical requirements. Industrial installations demonstrate tangible operational improvements: Chemical manufacturing plant (Frankfurt): Installation of cartouche de charbon actif in solvent recovery units achieved documented results: Hospital HVAC upgrade (Stockholm): Implementation of cartouche de filtre à air au charbon actif achieved: Municipal water treatment (Lyon): Custom élément filtrant au charbon actif installation addressed seasonal pesticide contamination: Research focuses on enhancing cartouche de charbon actif functionality while optimizing operational economics. Carbon nanotechnology developments aim to increase effective surface area beyond 2,500 m²/g using graphene-enhanced substrates. Pilot programs indicate such advancements could boost adsorption efficiency by 15-30% for specific VOCs. European environmental regulations regarding cartouche de filtre à air au charbon actif continue evolving, with EUROVENT projecting tighter particulate requirements under EN 1822 standards by 2026. Industry response includes development of composite carbon-silica gel configurations that simultaneously capture particulate and gaseous contaminants. Lifecycle cost management improvements focus on regeneration technologies allowing multiple reactivation cycles. Current testing shows promise for microwave regeneration methods restoring 92% of initial capacity over three cycles without degradation to the élément filtrant au charbon actif matrix. (cartouche de charbon actif) A: Activated carbon filter cartridges remove contaminants, odors, and chemicals from air or water. They use porous carbon to adsorb impurities like chlorine, VOCs, and bad smells. Commonly applied in air purifiers, water filters, and range hoods. A: Replacement typically occurs every 3-6 months, depending on usage and pollutant levels. Reduced airflow or lingering odors indicate it's time for a change. Always follow your device manufacturer's specific guidelines. A: While effective against gases and odors, standalone carbon filters don't capture viruses. Pair them with HEPA filters for pathogen removal. The carbon primarily targets volatile organic compounds (VOCs) and smoke particles. A: Activated carbon uses adsorption to trap microscopic pollutants chemically, unlike mechanical filters that catch larger particles. It neutralizes odors and chemicals rather than just collecting dust. Often integrated as an additional layer in multi-stage systems. A: It absorbs cooking fumes, smoke, and food odors efficiently. The carbon prevents grease buildup in ventilation systems. Ideal for range hoods to maintain clean indoor air quality.Ultra-high purity carbon (ash content <0.01%) in polypropylene cartridges prevents ionic contamination

ISO Class 1 compliance requires particle shedding below 0.05 particles/cm³ during operation

Implementation Case Studies Across Multiple Sectors

Future Development Trends in Carbon-Based Filtration

FAQS on cartouche de charbon actif

围绕活性炭滤芯的常见问题解答

Q: What is an activated carbon filter cartridge used for?

Q: How often should I replace a cartouche de charbon actif?

Q: Can a cartouche de filtre à air au charbon actif eliminate viruses?

Q: What's the difference between charbon actif and regular filters?

Q: Why use an élément filtrant au charbon actif in kitchens?

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: