Tel:

+8615930870079

Tel:

+8615930870079

Nën . 15, 2024 07:46 Back to list

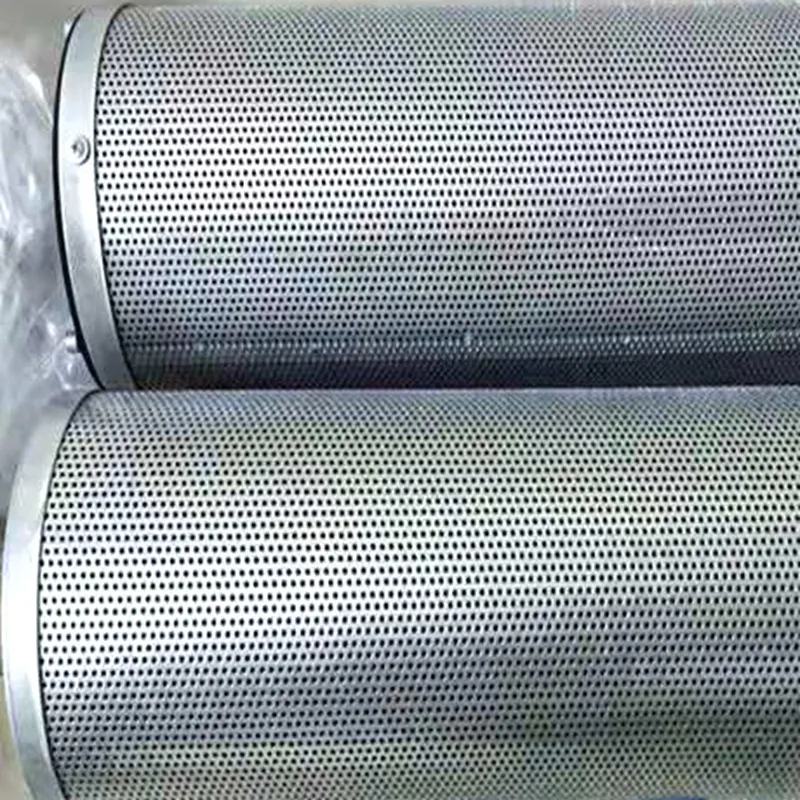

anti static filter cartridge

Understanding Anti-Static Filter Cartridges

In various industrial applications, effective filtration is critical for ensuring high-quality output and maintaining equipment integrity. One of the key innovations in filtration technology is the anti-static filter cartridge. These specialized components are designed to address both particulate capture and the dangers posed by static electricity in environments where explosive dust or volatile substances may be present.

What Is an Anti-Static Filter Cartridge?

An anti-static filter cartridge is a filtration device equipped with materials that mitigate the risks associated with static electricity buildup. Traditional filter cartridges are primarily designed to capture dust, allergens, and other particulates from the air or liquid streams. However, in certain industries—such as pharmaceuticals, food processing, and chemicals—static charge can lead to hazardous situations, including explosions or fires. Therefore, the anti-static feature provides an added layer of safety.

How Anti-Static Filter Cartridges Work

These filter cartridges utilize conductive materials that allow static charges to dissipate safely. By incorporating fibers or coatings that have conductive properties, the filter cartridges enable the controlled flow of electrical charges to ground, thereby reducing static buildup. When dust or other particles adhere to the filter media, they can become charged due to friction. An anti-static filter cartridge can prevent this accumulation of charge, which in turn minimizes the risk of spark generation and potential ignition of flammable materials.

The construction of these cartridges typically includes a blend of synthetic and natural fibers, with specific treatments to enhance their anti-static qualities. The effectiveness of the cartridge often depends on its design and the materials used; hence selecting the right product for a specific application is crucial.

Applications of Anti-Static Filter Cartridges

Anti-static filter cartridges find applications across numerous sectors. In the pharmaceutical industry, they are essential for maintaining cleanroom environments. The presence of static can lead to the unwanted contamination of products or materials; therefore, using these cartridges ensures a safer workspace.

anti static filter cartridge

In the food processing sector, anti-static filtration is vital to prevent the ignition of flour dust and other combustible particles

. By using anti-static filters, manufacturers can create safer production environments, protecting both the workforce and the integrity of the food products.Similarly, in chemical manufacturing, where volatile organic compounds (VOCs) may be present, the use of anti-static filter cartridges helps to mitigate risks associated with static charge accumulation, leading to safer handling and processing of materials.

Benefits of Using Anti-Static Filter Cartridges

The adoption of anti-static filter cartridges brings several advantages. First and foremost, they enhance safety by reducing the risk of static-related accidents. This is crucial not only for protecting employees but also for safeguarding the process equipment and the overall operation.

Moreover, anti-static filters improve the efficiency and longevity of the filtration system. As they prevent static from hindering airflow, these filters maintain optimal performance levels over time, ensuring consistent and reliable operation.

Finally, investing in specialized air filtration solutions like anti-static filter cartridges can result in compliance with safety regulations and standards, which is increasingly important in heavily regulated industries.

Conclusion

In conclusion, anti-static filter cartridges are a vital component in modern industrial filtration systems. Their ability to mitigate static electricity hazards while simultaneously providing effective particulate capture elevates their importance across various industries. As technology continues to evolve, the integration of anti-static features in filter cartridges will likely expand, offering even greater safety and efficiency in workplaces where static electricity poses a significant risk. By prioritizing the use of these advanced filtration solutions, industries can protect both their personnel and their products, leading to more sustainable and safe operations.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: