ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 13, 2025 13:23 Back to list

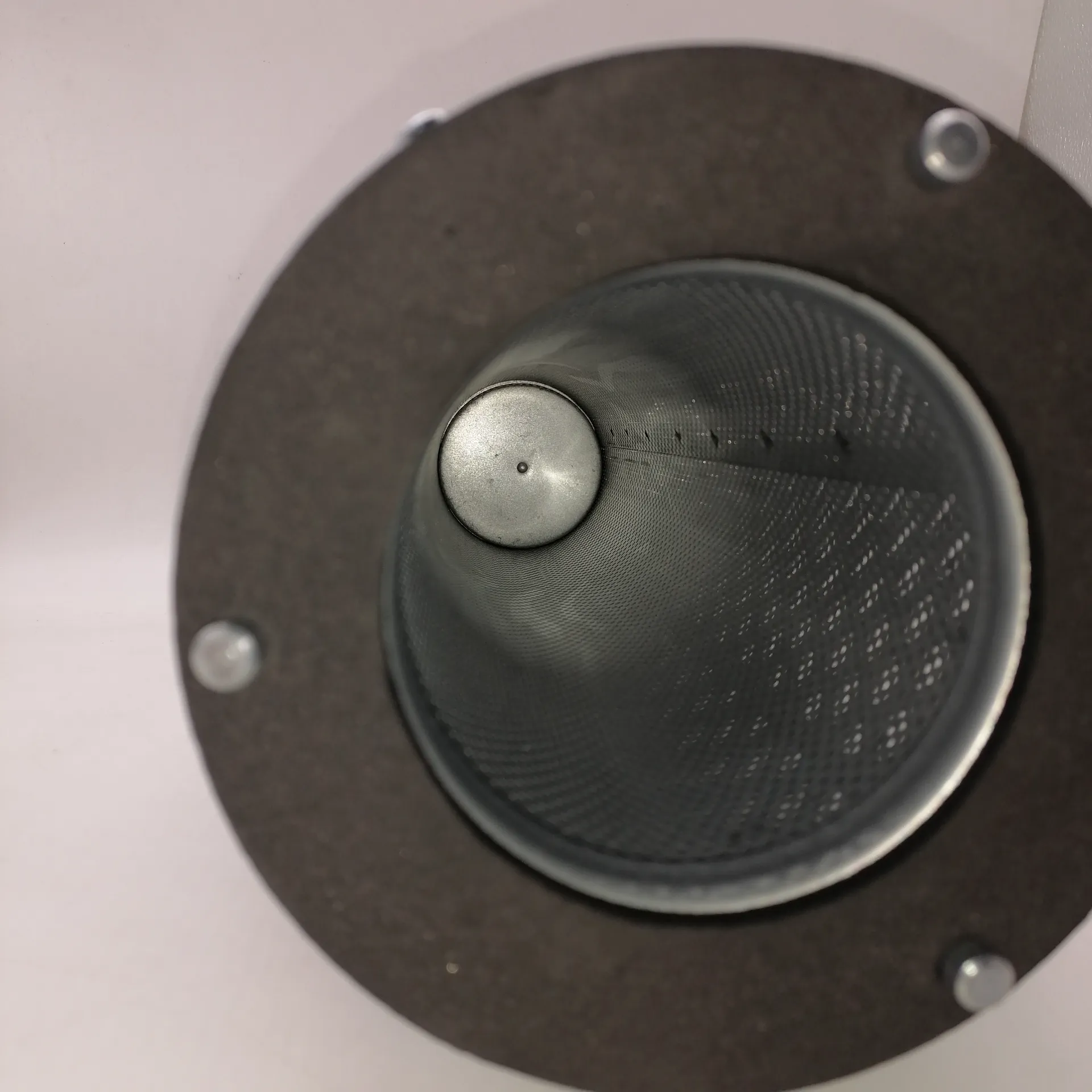

air filter cartridge

In industries that rely heavily on bulk material handling and storage, the efficiency and longevity of equipment can often depend on the lesser-known yet indispensable component the silo filter cartridge. For operations that involve storage silos, utilizing high-quality filter cartridges can significantly impact operational efficiency and product quality. This article explores the role of silo filter cartridges through the lens of experience, expertise, authoritativeness, and trustworthiness.

From an authoritativeness standpoint, leading manufacturers of silo filter cartridges provide certifications and third-party testing results that validate their products' efficiency and compliance with global standards. These documents are often detailed with specific data that supports the manufacturer's claims, giving users confidence in the cartridge's performance. Companies that invest in such authoritative testing not only demonstrate their commitment to quality but also establish themselves as leaders in the filtration industry. Trustworthiness is built through consistency in performance and reliability. When choosing a silo filter cartridge, it's crucial to consider the manufacturer's reputation and feedback from existing users. Reliable suppliers often offer detailed guidelines for installation and maintenance, which are essential for ensuring the longevity and effectiveness of the filter cartridges. Customer support, availability of replacement parts, and after-sale service further enhance the overall trust consumers place in these products. In practice, businesses benefit greatly from using proven, high-performance silo filter cartridges. Case studies highlight success stories where companies have managed to reduce downtime and maintenance costs thanks to the reliability and efficiency of these filters. For instance, a major agricultural company switched to a higher-grade of filter cartridge and reported not only reduced contamination incidents but also enhanced productivity as a result of fewer maintenance interruptions. In conclusion, the importance of selecting high-quality silo filter cartridges cannot be overstated. Not only do they play a critical role in maintaining material purity and operational efficiency, but they also uphold safety and environmental standards. With a deep understanding of the market's offerings, coupled with authoritative insights and trustworthy production practices, businesses can optimize their storage and handling systems, ultimately leading to improved outcomes and sustained success in their respective industries.

From an authoritativeness standpoint, leading manufacturers of silo filter cartridges provide certifications and third-party testing results that validate their products' efficiency and compliance with global standards. These documents are often detailed with specific data that supports the manufacturer's claims, giving users confidence in the cartridge's performance. Companies that invest in such authoritative testing not only demonstrate their commitment to quality but also establish themselves as leaders in the filtration industry. Trustworthiness is built through consistency in performance and reliability. When choosing a silo filter cartridge, it's crucial to consider the manufacturer's reputation and feedback from existing users. Reliable suppliers often offer detailed guidelines for installation and maintenance, which are essential for ensuring the longevity and effectiveness of the filter cartridges. Customer support, availability of replacement parts, and after-sale service further enhance the overall trust consumers place in these products. In practice, businesses benefit greatly from using proven, high-performance silo filter cartridges. Case studies highlight success stories where companies have managed to reduce downtime and maintenance costs thanks to the reliability and efficiency of these filters. For instance, a major agricultural company switched to a higher-grade of filter cartridge and reported not only reduced contamination incidents but also enhanced productivity as a result of fewer maintenance interruptions. In conclusion, the importance of selecting high-quality silo filter cartridges cannot be overstated. Not only do they play a critical role in maintaining material purity and operational efficiency, but they also uphold safety and environmental standards. With a deep understanding of the market's offerings, coupled with authoritative insights and trustworthy production practices, businesses can optimize their storage and handling systems, ultimately leading to improved outcomes and sustained success in their respective industries.

Next:

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: