Tel:

+8618931101301

Tel:

+8618931101301

dec. . 12, 2024 10:47 Back to list

turbine filter

Understanding Turbine Filters Importance and Applications

Turbine filters are essential components used in various industries, particularly in the realm of mechanical engineering, energy production, and environmental management. These sophisticated filtration systems are designed to remove impurities and particulate matter from fluids, thereby enhancing the efficiency and longevity of turbines and similar machinery.

What are Turbine Filters?

At their core, turbine filters are devices that screen out contaminants from the air or fluid before it enters a turbine system. They operate by utilizing a mesh or porous material that traps undesired particles. Depending on the design and operational requirements, these filters can range from simple screens to complex multi-layer filtration systems.

The function of turbine filters extends beyond mere cleanliness; they protect critical components such as bearings, rotors, and blades by ensuring that only clean fluids enter the system. This is particularly crucial in environments where dust, dirt, or other particulates are prevalent, such as in power plants, manufacturing facilities, and even aircraft.

Importance of Turbine Filters

The importance of turbine filters cannot be overstated. First and foremost, they play a significant role in maintaining the efficiency of turbine operations. By filtering out harmful contaminants, these devices help prevent wear and tear on turbine components, which can lead to costly repairs or even catastrophic failures. This not only protects the investment in the machinery but also maximizes the operational lifespan and performance.

Additionally, turbine filters contribute to energy efficiency. Contaminants can create friction and resistance within the turbine, which ultimately consumes more energy to operate. Clean systems run more smoothly, requiring less power and resulting in lower operational costs. Therefore, regular maintenance and replacement of turbine filters become critical to achieving optimal performance.

Design and Functionality

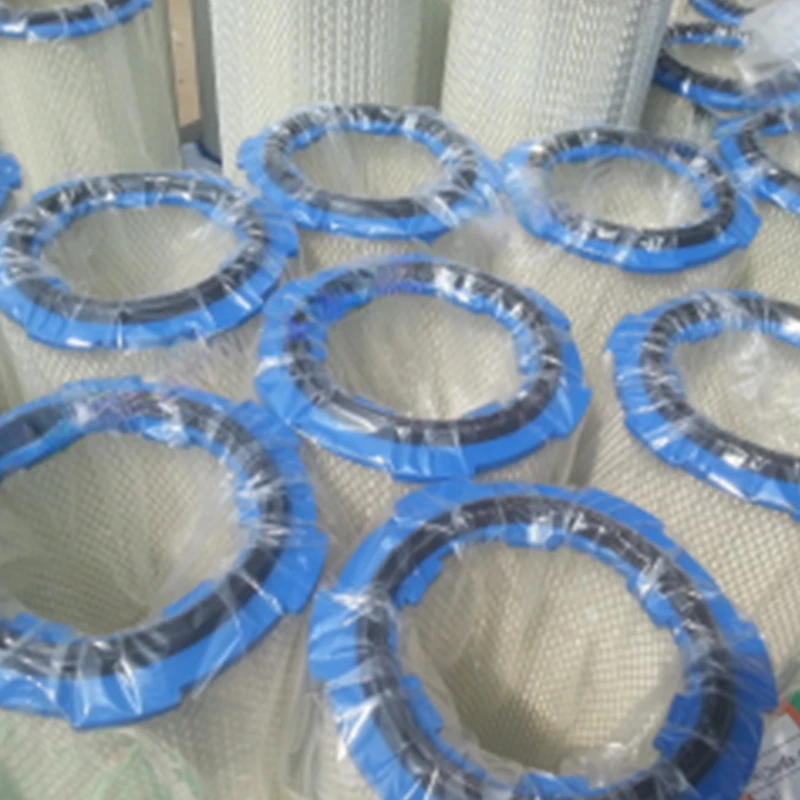

turbine filter

Turbine filters come in various designs, each tailored to specific applications. For instance, in gas turbines, where high temperatures and pressures are prevalent, the filters must withstand extreme conditions while efficiently trapping fine particulates. Conversely, in hydraulic systems, filters are designed to remove larger debris without obstructing flow.

The materials used to construct turbine filters also vary. Advanced synthetic materials are often employed to enhance durability and filtration efficiency. Some filters utilize a combination of mechanical and electrostatic principles to maximize contaminant capture without significantly impeding fluid flow.

Applications of Turbine Filters

Turbine filters find applications across numerous fields. In power generation, they are crucial in both renewable and non-renewable energy systems. Wind and hydroelectric plants use turbine filters to ensure optimal performance of their turbines, while fossil fuel plants use them to minimize particulate emissions into the environment.

In aviation, turbine filters are integral for maintaining engine performance. Airborne contaminants can severely affect engine efficiency and safety, making the use of high-quality air filters a necessity.

Moreover, in industrial processes, turbine filters help maintain the cleanliness of hydraulic systems, ensuring machinery operates efficiently and safely.

Conclusion

In conclusion, turbine filters are vital components that play a key role in the performance and longevity of turbine systems. Their ability to remove contaminants not only protects critical machinery but also enhances energy efficiency and operational safety. As technology advances, turbine filters are becoming increasingly sophisticated, utilizing advanced materials and designs to meet the demands of modern industries. Regular maintenance of these filters is essential for ensuring that turbines operate at peak performance, safeguarding investments and promoting sustainability across various sectors. The future of turbine technology undoubtedly hinges on the continued evolution of filtration systems, making turbine filters an area of great interest for ongoing research and development.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: