Tel:

+8615930870079

Tel:

+8615930870079

sept. . 28, 2024 20:01 Back to list

Optimizing Performance with High-Quality Metal Filter Elements for Industrial Applications

The Importance of Metal Filter Elements in Industrial Applications

Metal filter elements have become a pivotal component in various industrial processes, offering superior performance in filtration and separation applications. As industries continuously seek greater efficiency and reliability, these filters have garnered significant attention due to their unique properties and the advantages they bring to the table. In this article, we'll explore the significance of metal filter elements, their applications, and the benefits they provide.

What Are Metal Filter Elements?

Metal filter elements are filtration solutions made from various metals, typically stainless steel, aluminum, or other alloys. They are designed to remove particles, contaminants, and impurities from liquids and gases in industrial systems. The design of these filters varies, from sintered metal filters to porous metal membranes, ensuring a diverse range of filtration options tailored to specific operational needs.

Applications of Metal Filter Elements

Metal filter elements are employed in a wide array of industries. Some of the most common applications include

1. Oil and Gas Industry In oil and gas extraction and processing, metal filters are essential for separating solids from fluids. They protect equipment from damage caused by particulate contamination, ensuring optimal performance.

2. Chemical Processing Chemical plants utilize metal filter elements to ensure product purity and maintain process efficiency. These filters can withstand harsh chemicals and extreme temperatures, making them ideal for challenging environments.

3. Water Treatment Metal filter elements are utilized in water treatment facilities to remove sediment and other impurities from water sources. Their durability and effectiveness help in providing clean water, essential for both human consumption and industrial applications.

4. Pharmaceutical Manufacturing In the pharmaceutical industry, the purity of products is of utmost importance. Metal filters serve as reliable barriers against contaminants, ensuring that pharmaceutical products meet stringent regulatory standards.

5. Food and Beverage Processing Metal filters ensure the safety and quality of food and beverages by removing unwanted particles. Their ability to withstand high temperatures and cleaning processes makes them suitable for this sector.

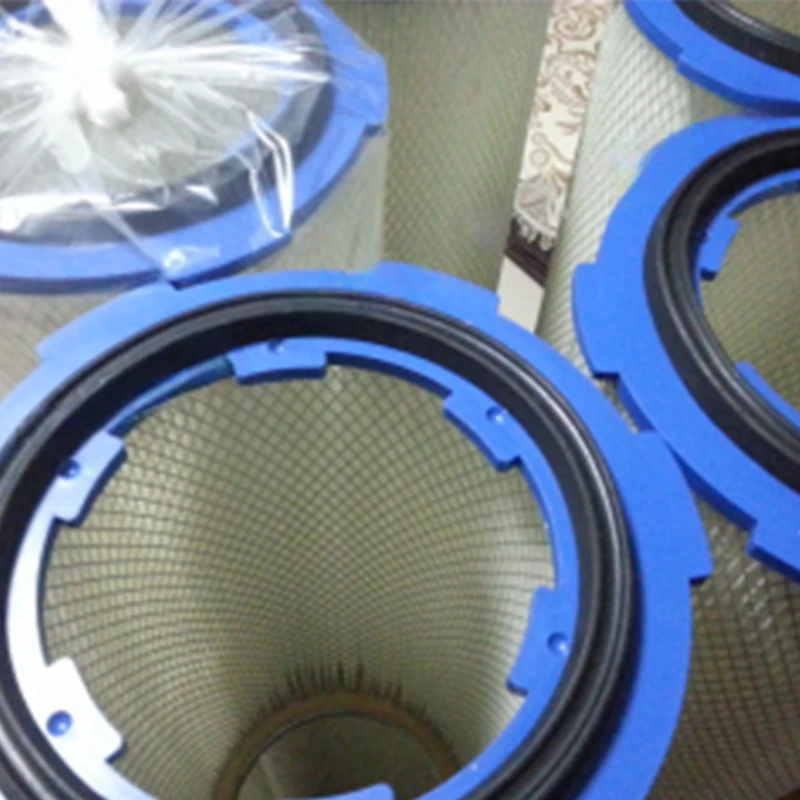

metal filter element

Advantages of Metal Filter Elements

The use of metal filter elements offers numerous benefits over traditional filtration methods

1. Durability Metal filters are robust and can handle extreme conditions — high temperatures, pressures, and corrosive environments. This durability translates to longer service life and reduced replacement costs.

2. High Filtration Efficiency With the ability to filter out a wide range of particle sizes, metal filter elements provide high filtration efficiency, ensuring cleaner results compared to conventional filters.

3. Easy Cleaning and Maintenance Many metal filter elements can be cleaned and reused, which reduces waste and lowers operating costs. Technologies such as backwashing or chemical cleaning further enhance their usability.

4. Customizability Metal filters can be custom-manufactured to meet specific requirements, including porosity, thickness, and shape, making them versatile solutions for various industrial needs.

5. Sustainability As industries move toward more sustainable practices, metal filters represent an eco-friendly option. Their longevity and ability to be reused diminish waste and promote a circular economy.

6. Increased Process Reliability By removing contaminants effectively, metal filter elements enhance the reliability of industrial processes, minimizing downtime and increasing productivity.

Conclusion

In summary, metal filter elements play a critical role in various industries, providing efficient, durable, and reliable filtration solutions. Their applications span multiple sectors, including oil and gas, chemical processing, water treatment, pharmaceuticals, and food and beverage manufacturing. With advantages like high filtration efficiency, ease of maintenance, and sustainability, metal filter elements are set to continue their vital role in advancing industrial processes across the globe. As technology evolves, we can expect these filters to integrate even more seamlessly into innovative filtration and separation systems, securing their place in the future of industrial operation.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: