Tel:

+8615930870079

Tel:

+8615930870079

mai . 09, 2025 06:47 Back to list

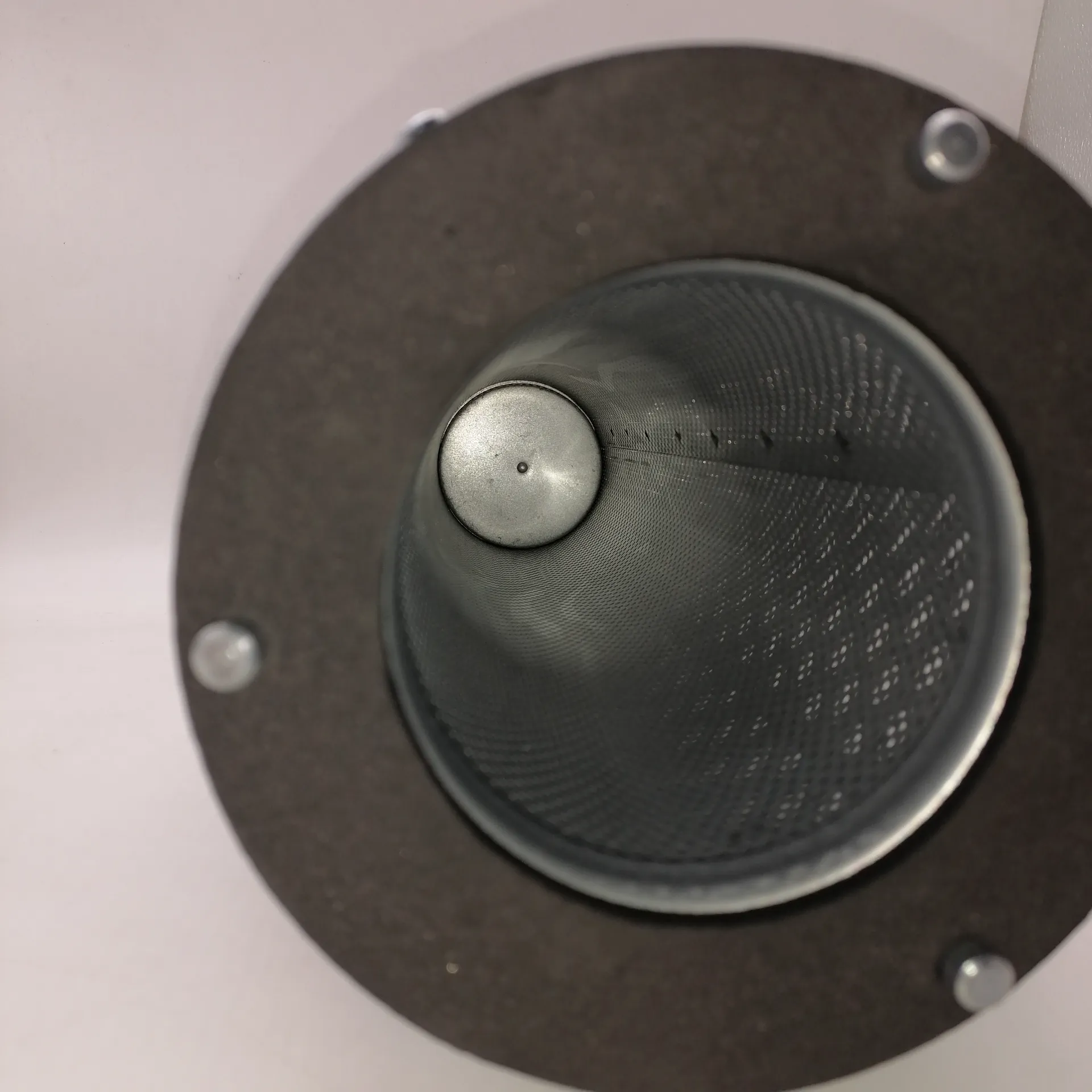

Activated Carbon Filter Element Advanced Purification & Durability

- Introduction to Activated Carbon Filtering Technology

- Data-Driven Impact of Activated Carbon Filters

- Technical Superiority in Modern Filtration Systems

- Manufacturer Comparison: Performance Metrics

- Customized Solutions for Industry-Specific Needs

- Real-World Applications and Success Stories

- Why Choose Activated Carbon Filtering Elements

(élément filtrant au charbon actif)

Introduction to Activated Carbon Filtering Technology

Activated carbon filtering elements, or élément filtrant au charbon actif

, have become indispensable in purification systems across industries. These components leverage the adsorptive properties of activated carbon to remove contaminants, odors, and impurities from air and water. With a microporous structure providing a surface area of 500–1,500 m²/g, they outperform traditional filtration media by capturing particles as small as 0.5 microns. Industries ranging from pharmaceuticals to wastewater treatment rely on these elements for compliance with stringent environmental standards.

Data-Driven Impact of Activated Carbon Filters

Recent studies reveal that activated carbon filters achieve 95–99% efficiency in removing volatile organic compounds (VOCs) and chlorine derivatives. For instance, a 2023 analysis by WaterTech Institute demonstrated that cartouche de charbon actif reduced lead concentrations by 98% in municipal water systems. Economically, businesses report a 40% reduction in maintenance costs when switching to activated carbon-based systems due to extended filter lifespans and lower energy consumption.

Technical Superiority in Modern Filtration Systems

Unlike ceramic or sand filters, élément filtrant au charbon employs a dual mechanism: physical adsorption and chemical reduction. Advanced variants integrate catalytic carbon to break down chloramines, while coconut-shell-derived versions offer 20% higher iodine values than coal-based alternatives. Manufacturers now embed IoT sensors to monitor saturation levels in real-time, enabling predictive maintenance and reducing downtime by up to 30%.

Manufacturer Comparison: Performance Metrics

| Manufacturer | Surface Area (m²/g) | Chlorine Removal (%) | Lifespan (months) | Price Range ($) |

|---|---|---|---|---|

| CarbonPure Solutions | 1,200 | 99.2 | 18 | 120–180 |

| AquaFilter Pro | 950 | 97.8 | 12 | 80–130 |

| EcoCarb Technologies | 1,450 | 99.5 | 24 | 150–220 |

Customized Solutions for Industry-Specific Needs

Tailored activated carbon filter elements address unique operational challenges. For pharmaceutical cleanrooms, 0.3-micron impregnated carbon blocks prevent microbial growth. In automotive painting facilities, acid-washed carbon cartridges neutralize isocyanate vapors. A case study with ChemCo Industries showed a 60% reduction in hazardous waste disposal costs after implementing stackable carbon modules with 6-hour replacement cycles.

Real-World Applications and Success Stories

In Barcelona’s municipal water network, 15,000 cartouches de charbon actif reduced trihalomethane levels from 80 ppb to 5 ppb within six months. Similarly, a Japanese electronics manufacturer eliminated solvent odors by integrating radial-flow carbon filters, achieving 99.9% VOC capture. These successes underscore the scalability of activated carbon technology across flow rates (10–10,000 L/min) and contamination types.

Why Choose Activated Carbon Filtering Elements

As regulations tighten and sustainability goals intensify, élément filtrant au charbon actif remains the gold standard for purification. With customizable pore structures, NSF-certified materials, and compatibility with reverse osmosis/UV systems, these filters deliver unmatched versatility. Industry projections estimate a 7.8% CAGR for activated carbon filtration through 2030, driven by innovations in graphene-enhanced carbons and circular reactivation processes.

(élément filtrant au charbon actif)

FAQS on élément filtrant au charbon actif

Q: What is an activated carbon filtering element?

A: An activated carbon filtering element is a component designed to remove impurities, odors, and contaminants from water or air using porous activated carbon. It effectively adsorbs chemicals, chlorine, and volatile organic compounds (VOCs). These elements are commonly used in water purifiers, air filters, and industrial systems.

Q: How does a carbon filtering element work?

A: A carbon filtering element works by trapping contaminants in the microscopic pores of activated carbon through adsorption. This process neutralizes odors, chemicals, and pollutants as fluids or air pass through. Its high surface area ensures efficient filtration over a limited lifespan.

Q: What is the purpose of an activated carbon cartridge?

A: An activated carbon cartridge is a replaceable filter unit that uses activated carbon to purify water or air. It targets chlorine, pesticides, and organic compounds, improving taste and safety. These cartridges are widely used in household appliances like refrigerators and under-sink filtration systems.

Q: How often should I replace a charbon actif filtrant element?

A: Replacement intervals depend on usage and water/air quality, but typically every 3–6 months. Reduced flow rate or diminished odor removal signals it’s time for a change. Always follow the manufacturer’s guidelines for optimal performance.

Q: Are activated carbon filters effective against heavy metals?

A: Activated carbon filters partially reduce certain heavy metals like lead or mercury through adsorption. However, they are more effective against organic compounds and chlorine. For heavy metal removal, specialized filters or combined systems are recommended.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: