Tel:

+8615930870079

Tel:

+8615930870079

dec. . 01, 2024 06:53 Back to list

Top Manufacturers of Air Intake Filters for Gas Turbines

The Importance of Gas Turbine Air Intake Filters A Look at Manufacturers

Gas turbines are an integral part of modern energy production, playing a crucial role in electricity generation, aviation, and various industrial applications. One of the key components that ensure the efficient operation of gas turbines is the air intake filter. The air intake filter plays a vital role in maintaining the cleanliness and efficiency of the air entering the turbine, which directly influences performance, reliability, and longevity. Consequently, the choice of air intake filter manufacturer can significantly impact the overall performance of a gas turbine.

The Role of Air Intake Filters

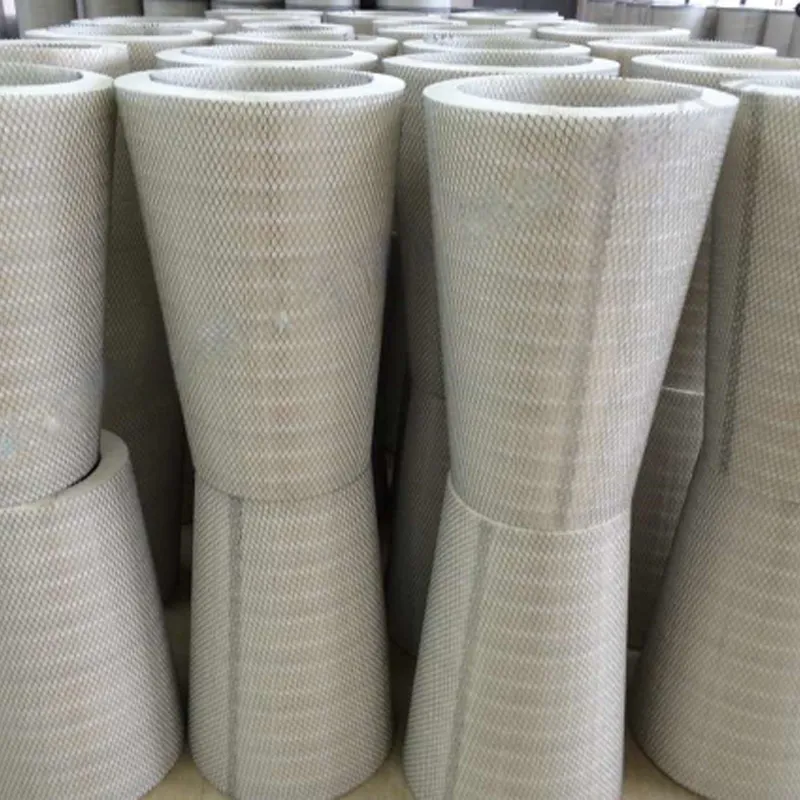

Gas turbine air intake filters are designed to remove particulates and contamination from the air before it enters the combustion chamber. Contaminants such as dust, dirt, pollen, and industrial pollutants can severely hamper turbine performance by causing wear and tear on the blades and other components. A high-quality air intake filter can protect the turbine and enhance its efficiency, leading to lower operational costs and reduced emissions.

In addition to performance, air intake filters also play a role in regulatory compliance. Many regions have stringent environmental regulations that govern the emissions from gas turbines. Effective filtration systems can help operators meet these standards and avoid potential fines or shutdowns due to non-compliance.

Key Features of Quality Air Intake Filters

When selecting an air intake filter manufacturer, various characteristics should be considered. Leading manufacturers often provide filters that have

1. High Filtration Efficiency Filters must be able to capture a significant percentage of particulate matter without excessively restricting airflow. This balance is critical to maintaining optimum turbine performance.

2. Durability The filters should be constructed from robust materials that can withstand the high temperatures and pressures found in turbine environments. Longevity is essential to reduce the frequency of maintenance and replacement.

3. Customizability Different turbine models and operational environments may require specific filtration solutions. Leading manufacturers often offer customizable filter options to ensure compatibility and optimal performance.

4. Ease of Maintenance Maintenance and replacement should be straightforward to minimize downtime. Many manufacturers offer filters designed for quick and easy service, ensuring that turbines can remain operational with minimal interruptions.

gas turbine air intake filter manufacturers

5. Environmental Considerations Some manufacturers focus on sustainable practices, offering filters that are recyclable or made from environmentally friendly materials. This is increasingly important as industries strive to reduce their ecological footprint.

Leading Manufacturers in the Market

Several companies are well-known in the gas turbine air intake filter manufacturing industry, each known for their commitment to quality and innovation. Here are a few noteworthy names

1. Donaldson Company, Inc. A leader in filtration technologies, Donaldson offers a wide range of air intake filters specifically designed for gas turbines. Their products are known for their high efficiency and durability.

2. Parker Hannifin Corporation With a strong focus on technological advancement, Parker Hannifin provides filtration solutions that enhance turbine performance while ensuring compliance with environmental regulations.

3. AFC Energy This company specializes in advanced filtration systems for gas turbines, offering customized solutions that meet the varying needs of different applications and environments.

4. 3M Company Known for their innovation across various industries, 3M’s filtration solutions for gas turbines reflect their commitment to quality and effectiveness.

5. Air Filtration Inc. Focusing on custom solutions, Air Filtration Inc. has established a reputation for providing tailored filters that optimize performance for specific turbine models.

Conclusion

Choosing the right air intake filter manufacturer is vital for the efficient operation of gas turbines. High-quality filters not only protect turbine components but also contribute to overall environmental compliance and operational efficiency. As the demand for energy continues to grow, the importance of reliable and effective air filtration systems in gas turbines becomes increasingly paramount. By investing in quality air intake filters from reputable manufacturers, operators can ensure the performance, longevity, and sustainability of their gas turbine systems.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: