Tel:

+8615930870079

Tel:

+8615930870079

dec. . 28, 2024 07:09 Back to list

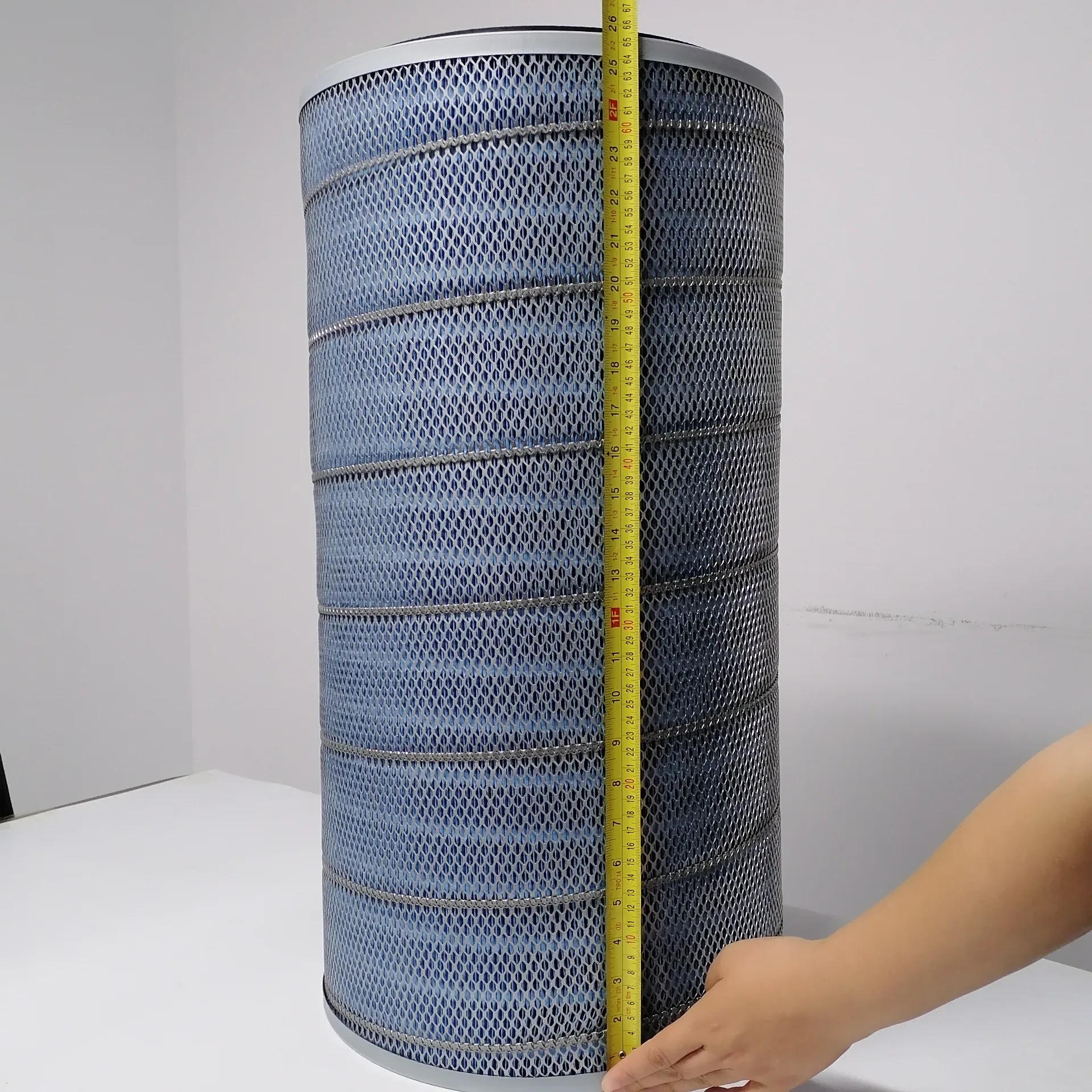

gas turbine air intake filter

Gas Turbine Air Intake Filters Enhancing Performance and Efficiency

Gas turbines are critical components in various industries, serving as the backbone for power generation and propulsion systems. One of the key factors that influences the performance and longevity of gas turbines is the quality of the air they intake. To ensure optimal efficiency, the use of air intake filters is paramount. This article delves into the importance of gas turbine air intake filters, their types, maintenance considerations, and advancements in filtration technology.

The Importance of Air Quality in Gas Turbines

Gas turbines operate by drawing in ambient air, compressing it, mixing it with fuel, and igniting the mixture to generate power. The quality of this air is crucial; contaminants such as dust, dirt, and other particulate matter can significantly impair turbine performance. Impurities can lead to excessive wear and tear on critical components, resulting in increased maintenance costs and unplanned outages. Consequently, effective air intake filtration is vital not only for protecting the turbine but also for optimizing its efficiency and extending its operational life.

Types of Air Intake Filters

Gas turbine air intake filters come in various types, with the most common being mechanical filters, electrostatic filters, and HEPA filters.

1. Mechanical Filters These are typically made from materials like synthetic fibers or fiberglass. They work by trapping larger particles while allowing air to flow freely. Mechanical filters are often used as the first line of defense against contaminants.

2. Electrostatic Filters These filters utilize an electric charge to capture smaller particles that might pass through mechanical filters. They are effective in enhancing the overall filtration efficiency, particularly for fine dust and smoke.

3. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to capture at least 99.97% of particles that are 0.3 microns in diameter. These filters are especially beneficial in environments with stringent air quality requirements, as they significantly reduce the risk of particulate contamination.

gas turbine air intake filter

Maintenance Considerations

Regular maintenance of air intake filters is essential to ensure their effectiveness. Over time, filters can become clogged with particles, which can restrict airflow and decrease turbine efficiency. The frequency of maintenance depends on various factors, including the environment in which the turbine operates, the level of air pollution, and the specific design of the filter system.

Inspection and replacement protocols should be established to monitor the condition of the filters. Operators can use differential pressure gauges to assess the pressure drop across the filters, indicating when they require cleaning or replacement. Additionally, employing predictive maintenance strategies can help in identifying potential issues before they result in significant downtime.

Advancements in Filtration Technology

Recent advancements in filtration technology are paving the way for improved performance of gas turbine air intake systems. Innovations such as nanofiber technology have emerged, offering filters that can capture smaller particles without significantly affecting airflow. These advanced materials not only enhance the filtration efficiency but also prolong the lifespan of filters, leading to lower maintenance costs.

Furthermore, the integration of smart monitoring systems with artificial intelligence can provide real-time data on filter performance. These systems can analyze trends and predict when maintenance should occur, thus optimizing operational efficiency.

Conclusion

Gas turbine air intake filters play a crucial role in ensuring the reliability and efficiency of gas turbines. As industries continue to evolve and prioritize sustainability, maintaining high air quality through effective filtration will become increasingly important. By investing in advanced filter technologies and adhering to rigorous maintenance protocols, operators can safeguard their gas turbines against contamination, ultimately enhancing performance and extending the life of these vital machines. The future of gas turbines lies not only in their engineering excellence but also in the effective management of the air they consume.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: