Tel:

+8615930870079

Tel:

+8615930870079

nov. . 26, 2024 22:32 Back to list

High Efficiency Cartridge Filters for Dust Extraction Systems in Industrial Applications

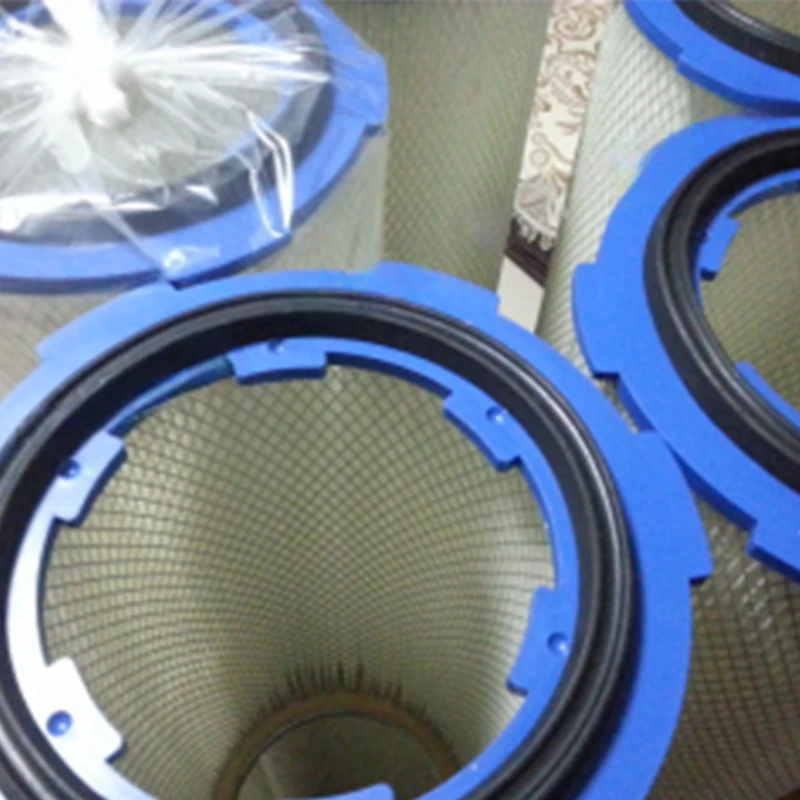

Fine Cartridge Filter for Dust Extractor Key to Efficient Air Filtration

In various industries, efficient dust extraction is crucial to maintaining a clean and safe working environment. One of the vital components in achieving optimal dust filtration is the fine cartridge filter. These filters play an essential role in removing airborne particles and ensuring the health and safety of workers, while also enhancing the performance and longevity of dust extraction systems.

Understanding Fine Cartridge Filters

Fine cartridge filters are specialized filtration devices designed to capture and retain dust particles of varying sizes. These filters consist of a cylindrical structure filled with a porous medium, which allows air to pass through while trapping contaminants. The filter's fine mesh or fiber structure is engineered to provide high filtration efficiency, typically capturing particles as small as 0.5 microns. This capability is vital in industries such as woodworking, metalworking, pharmaceuticals, and food processing, where high levels of dust and particulate matter can pose serious health risks.

Benefits of Fine Cartridge Filters

1. High Filtration Efficiency The primary advantage of fine cartridge filters is their ability to filter out fine particulates effectively. This ensures that the air released back into the environment is clean and safe, reducing the risk of respiratory issues and other health problems among employees.

2. Longer Filter Life Unlike traditional bag filters, fine cartridge filters typically have a larger surface area relative to their size, allowing them to hold more dust before needing replacement. This results in lower maintenance costs and less downtime for dust extraction systems.

3. Energy Efficiency Fine cartridge filters are designed to maintain a low pressure drop, which means they don't require excessive energy to operate. When a filtration system works more efficiently, energy consumption decreases, leading to lower operational costs.

4. Easy Maintenance and Replacement Many fine cartridge filters come with features that make them easier to replace and maintain. Plug-and-play designs allow operators to quickly swap out filters without requiring specialized tools or extensive downtime.

5. Versatility Fine cartridge filters can be used in a wide range of dust extraction applications, accommodating various industries and processes. They can be tailored to specific requirements based on the type of dust being filtered, making them a versatile choice for any facility.

fine cartridge filter for dust extractor

Selecting the Right Fine Cartridge Filter

When selecting a fine cartridge filter for a dust extractor, several factors must be considered

1. Dust Type Identify the type of dust generated in the facility. Different materials (wood, metal, chemicals) require different filtration solutions.

2. Filter Efficiency Assess the specific efficiency rating needed for the application. Higher efficiency ratings (like HEPA) may be necessary for hazardous dust.

3. Airflow Requirements Understand the airflow needs of your dust extraction system and ensure that the selected filter can handle these requirements without causing excessive pressure drops.

4. Operating Environment Consider the environmental conditions, such as temperature and humidity, which can affect filter performance.

5. Regulatory Compliance Ensure that the chosen filters meet industry regulations related to air quality and safety standards.

Conclusion

Investing in a high-quality fine cartridge filter for your dust extractor is essential for achieving optimal air quality and maintaining a safe working environment. With their high filtration efficiency, longer lifespan, and energy-saving capabilities, these filters enhance the overall performance of dust extraction systems. By taking the time to select the right filter based on specific operational needs and conditions, businesses can protect their workforce and comply with environmental regulations, ultimately leading to a healthier and more productive workplace.

In summary, fine cartridge filters represent an indispensable element in the modern industrial landscape—providing efficient dust removal, contributing to worker safety, and promoting operational efficiency.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: