Tel:

+8618931101301

Tel:

+8618931101301

oct. . 11, 2024 01:48 Back to list

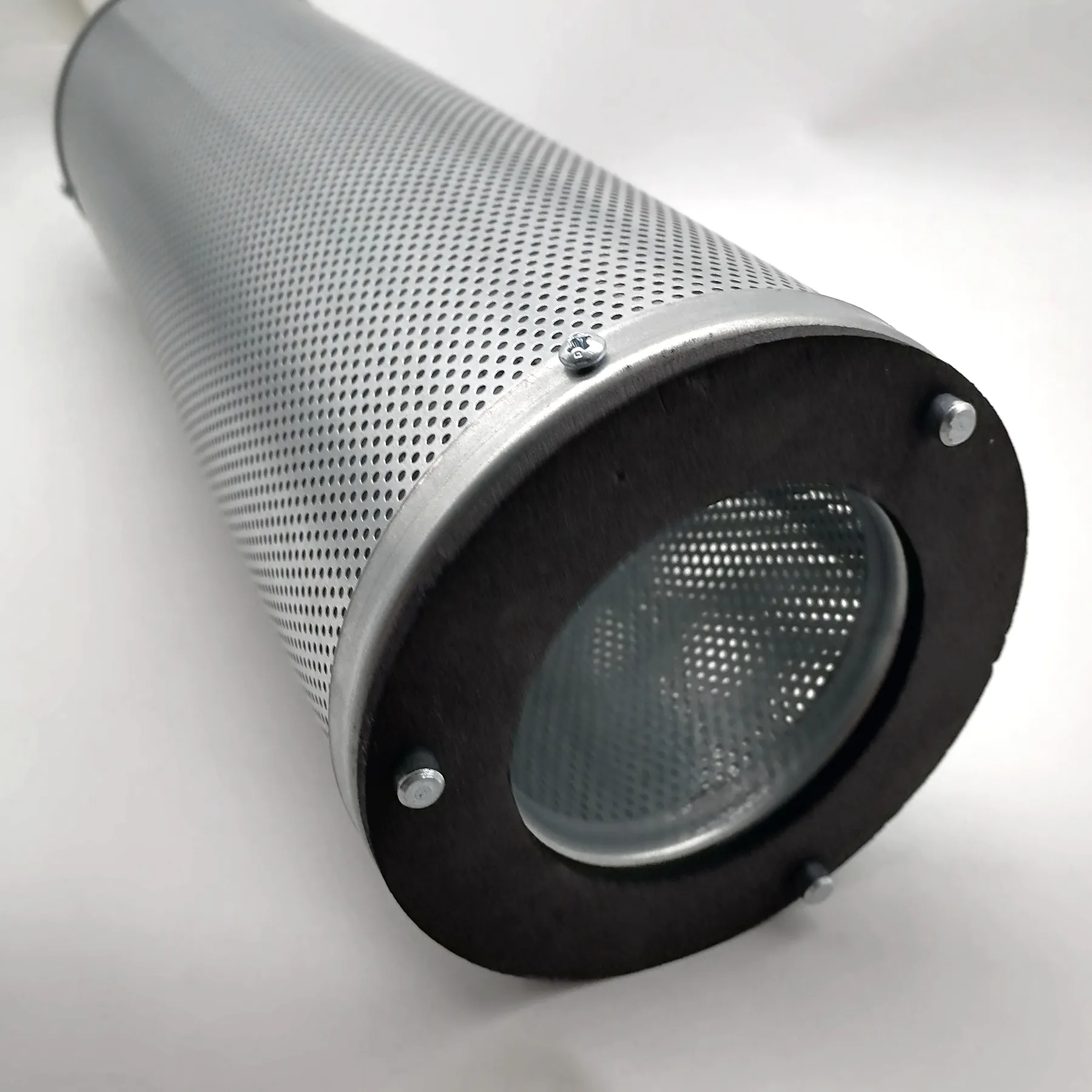

dust filter cartridge

Understanding Dust Filter Cartridges The Key to Clean Air

In today's world, maintaining clean air quality is of paramount importance, both for environmental sustainability and for ensuring the health and well-being of individuals. A crucial component in achieving this goal is the dust filter cartridge, a device designed to remove airborne particulates from air streams in various industrial and commercial applications. This article delves into the importance, functionality, and types of dust filter cartridges, as well as their role in different industries.

The Importance of Dust Filter Cartridges

Dust filter cartridges serve a critical role in air filtration systems. They are specifically engineered to capture and retain dust, dirt, and other particulates that can be harmful to humans, equipment, and the environment. Poor air quality can lead to respiratory issues, allergies, and other health concerns, making effective filtration essential. Moreover, industries that produce dust as a byproduct, such as woodworking, metalworking, pharmaceuticals, and food processing, must implement robust filtration systems to comply with safety regulations and protect workers.

How Dust Filter Cartridges Work

The operation of a dust filter cartridge is relatively simple yet highly effective. Airborne particles enter the filtration system and pass through the cartridge, which is made of various materials that vary based on the application and specific type of dust being filtered. The design often includes pleated filters that increase the surface area, allowing for a higher dust holding capacity and improved airflow.

As air flows through the cartridge, larger particles are captured on the surface, while smaller particles are trapped within the fibers of the filter material. Over time, the filter may become clogged with dust, necessitating regular maintenance and replacement to ensure optimal performance. Many modern filtration systems incorporate features such as pulse jet cleaning, which uses bursts of compressed air to dislodge accumulated particulates, extending the lifespan of the filter cartridge and maintaining airflow efficiency.

Types of Dust Filter Cartridges

Dust filter cartridges come in various shapes, sizes, and materials, each tailored to suit different applications. Some common types of dust filter cartridges include

1. Pleated Filter Cartridges Featuring multiple folds or pleats, these filters provide a larger surface area and excellent dust holding capacity. They are commonly used in both industrial and commercial settings.

dust filter cartridge

2. HEPA Filters High-Efficiency Particulate Air (HEPA) filters can capture 99.97% of particles as small as 0.3 microns. They are ideal for environments requiring strict air quality standards, such as hospitals and laboratories.

3. Activated Carbon Filters These filters are designed to adsorb gases and volatile organic compounds (VOCs). They are often used in settings where odors or harmful vapors need to be controlled, such as chemical processing facilities.

4. Synthetic Filters Made from materials like polyester or polypropylene, synthetic filters offer high dust holding capacity, durability, and resistance to moisture and chemicals. They are commonly found in various industrial applications.

5. Metal Mesh Filters These are reusable and can handle higher temperatures and more abrasive dust particles. They are often utilized in industrial processing environments.

The Role of Dust Filter Cartridges in Various Industries

Across multiple industries, dust filter cartridges play a vital role in maintaining air quality and ensuring compliance with health and safety regulations. In the woodworking industry, for instance, fine wood dust can pose significant health risks, making effective filtration essential. Similarly, in the mining and construction sectors, respirable silica dust is a serious hazard, necessitating high-quality dust collection systems equipped with effective cartridges.

In the food processing and pharmaceutical industries, where cleanliness is crucial, the use of HEPA filter cartridges ensures that even the smallest contaminants are captured, maintaining product safety and quality.

Conclusion

In conclusion, dust filter cartridges are an indispensable element of air filtration systems in various industrial and commercial applications. Their ability to efficiently capture harmful particulates not only protects the health of workers and consumers but also contributes to the overall well-being of the environment. As technology advances, the design and efficiency of dust filter cartridges continue to improve, promising even cleaner air for generations to come. Investing in quality filtration systems is not just a regulatory necessity; it is a commitment to a healthier future.

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

Email:

Email: