Tel:

+8618931101301

Tel:

+8618931101301

nov. . 22, 2024 00:58 Back to list

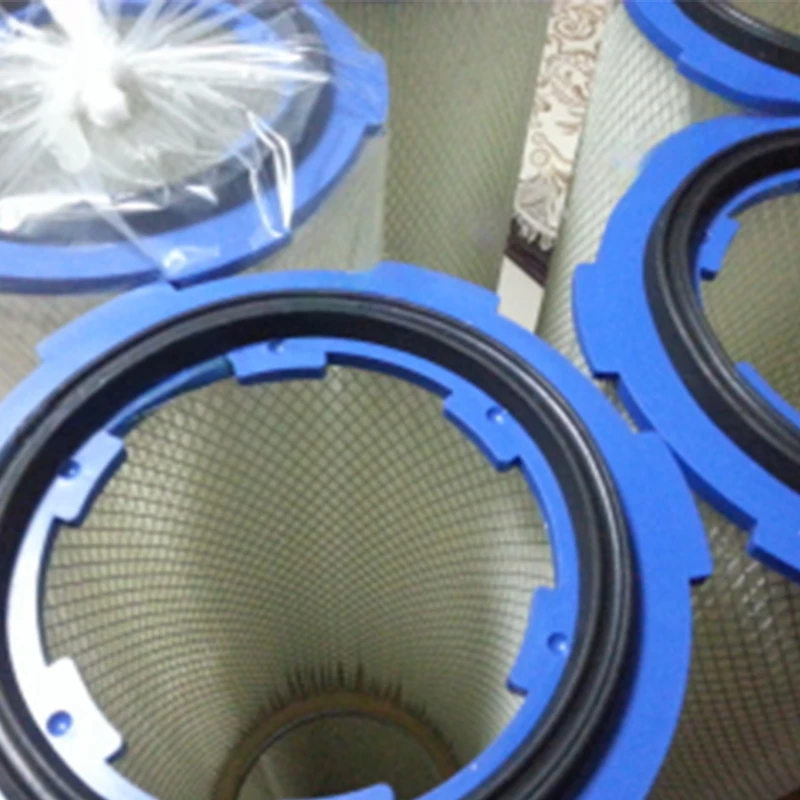

dust extractor pleated filter cartridges

Understanding Dust Extractor Pleated Filter Cartridges

In various industrial and commercial settings, managing dust and airborne contaminants is crucial for maintaining a clean and safe environment. Dust extractor systems play a vital role in this process, and one of the key components that enhance their efficiency is the pleated filter cartridge. This article will delve into the significance of dust extractor pleated filter cartridges, their construction, benefits, and maintenance.

What Are Dust Extractor Pleated Filter Cartridges?

Dust extractor pleated filter cartridges are specialized filtration devices designed to capture particulate matter in air and gas streams effectively. Unlike traditional filter designs, pleated filters feature a series of folds that increase the surface area available for capturing dust and particulate matter. This innovative design allows for better airflow while maintaining high filtration efficiency.

These cartridges are commonly used in various applications, including woodworking, metalworking, pharmaceuticals, food processing, and other industries where dust control is essential to ensure product quality and worker safety.

Construction and Design

The design of pleated filter cartridges is crucial to their performance. Typically made from synthetic or fiberglass materials, they are engineered to withstand harsh operating conditions. The pleated structure consists of several folds, allowing for a larger filtration area without significantly increasing the size of the cartridge itself. This design not only enhances dust collection capability but also extends the lifespan of the filter, as it can handle more dust before requiring replacement.

Additionally, pleated filter cartridges often feature a robust outer shell that provides structural integrity and allows for easy installation and replacement in dust extraction systems. Some cartridges are treated with electrostatic properties, which can further improve their dust collection efficiency by attracting and trapping smaller particulate matter.

Benefits of Using Pleated Filter Cartridges

1. Enhanced Filtration Efficiency Pleated filter cartridges can capture a broader range of particulate sizes, making them ideal for industries producing fine dust. Their efficient design ensures that even the smallest particles are effectively filtered out of the air.

dust extractor pleated filter cartridges

2. Longer Lifespan The increased surface area provided by the pleated design means that these cartridges can handle a higher dust load compared to traditional filters. This translates to longer service intervals and reduced operational costs for businesses.

3. Lower Resistance to Airflow The pleated structure allows for better airflow when compared to non-pleated filters. This means that dust extractors can operate more efficiently, reducing the energy consumption of the overall system.

4. Cost-Effectiveness While the initial investment in pleated filter cartridges may be higher than traditional filters, their durability and longevity often result in lower replacement costs over time. Additionally, improved airflow can lead to energy savings, making them a cost-effective choice in the long run.

5. Versatility Pleated filter cartridges can be used in a variety of dust extraction systems, including baghouse systems, cartridge collectors, and industrial vacuum systems. This versatility means that they can be adapted to meet the specific needs of different industries and applications.

Maintenance and Replacement

To maintain optimal performance, dust extractor pleated filter cartridges require regular inspection and cleaning. Depending on the operating environment, filters may need to be cleaned using compressed air or other cleaning methods. It is essential to follow the manufacturer's recommendations regarding maintenance and replacement schedules to ensure that the filtration system operates efficiently.

Regularly monitoring the pressure drop across the filter cartridge can help determine when it needs to be cleaned or replaced. A significant increase in pressure drop is an indicator that the filter is becoming clogged and may not be performing effectively.

Conclusion

Dust extractor pleated filter cartridges are crucial components in maintaining clean and safe environments in various industrial applications. Their advanced design allows for higher filtration efficiency, longer lifespans, and lower operational costs. As industries continue to prioritize air quality and worker safety, the role of pleated filter cartridges in dust extraction systems will remain paramount. Investing in quality pleated filter cartridges not only benefits the environment but also enhances the overall effectiveness of dust control measures, ensuring a healthier workspace for all.

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

Email:

Email: