Tel:

+8618931101301

Tel:

+8618931101301

nov. . 10, 2024 23:26 Back to list

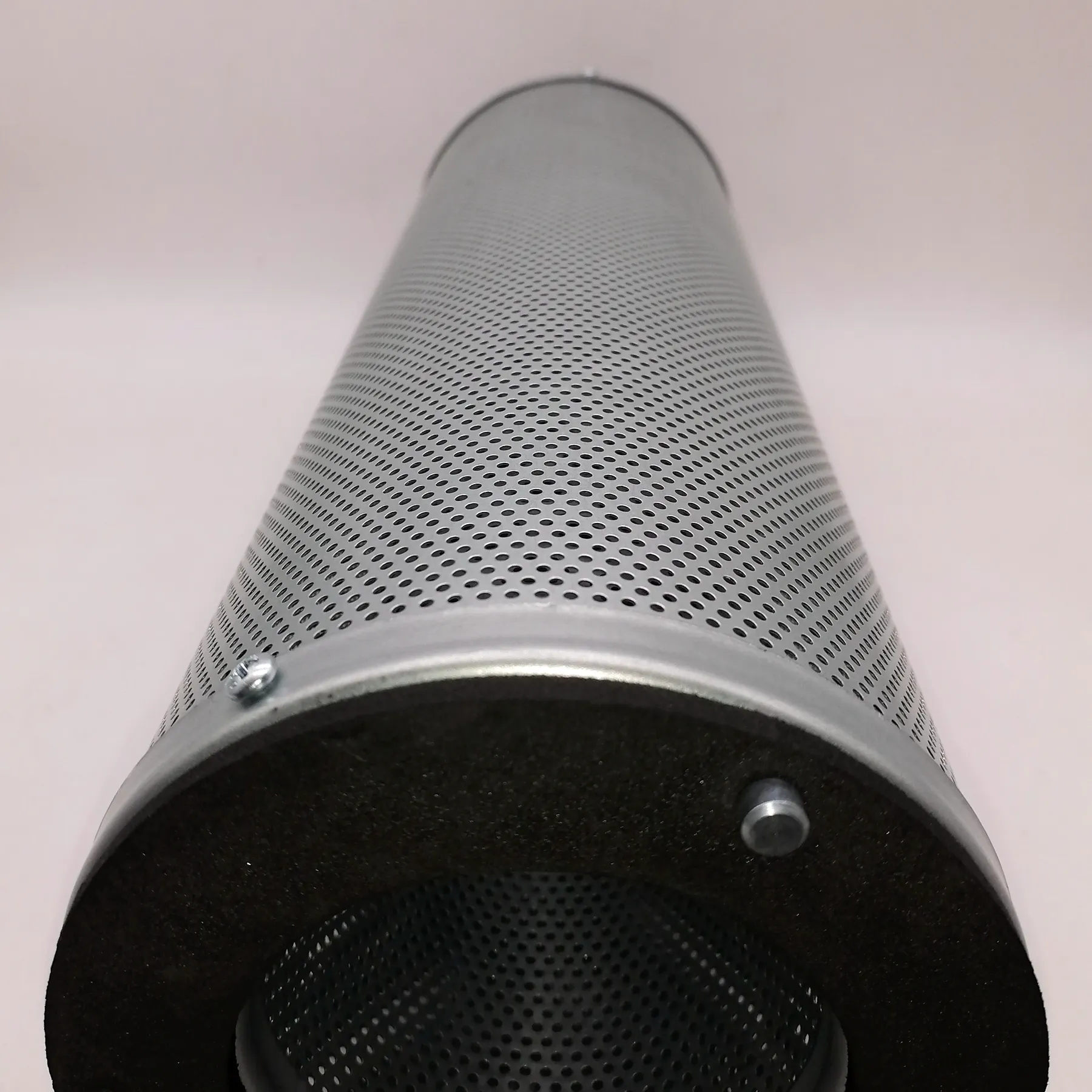

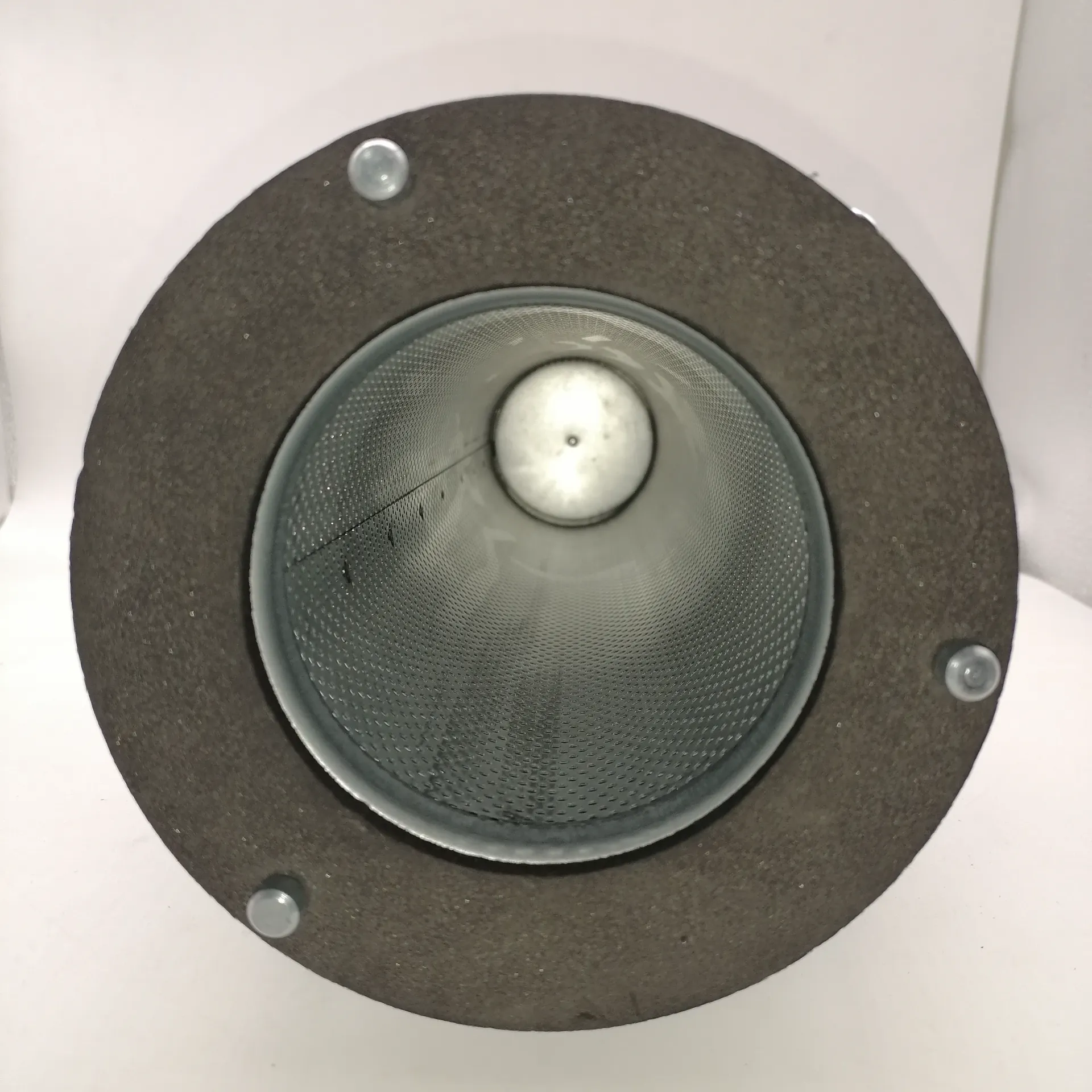

High-Efficiency Pleated Filter Cartridges for Dust Extractors and Air Filtration Systems

The Importance of Dust Extractor Pleated Filter Cartridges

In various industries, the management of dust and airborne particles is a critical aspect of maintaining a safe and productive work environment. Dust extractor systems play a vital role in this process, and at the heart of these systems are pleated filter cartridges. These cartridges are essential for effective dust collection and contribute significantly to the overall efficiency of dust extraction systems.

Understanding Pleated Filter Cartridges

Pleated filter cartridges are designed with a series of folds or pleats, which increase the surface area available for filtration. This design allows for enhanced dust and particle capture without a significant increase in resistance to airflow. The larger surface area means that dust and particulate matter can be collected more effectively, allowing for longer intervals between filter changes and reduced operational costs.

The pleating process ensures that the filters have a high dust-holding capacity, which translates to improved performance. As dust accumulates on the filter surface, the airflow through the filter may begin to decrease. However, the design of pleated cartridges allows for continued effective filtration longer than traditional bag filters, making them a preferred choice in many industrial applications.

Applications of Dust Extractor Pleated Filter Cartridges

Pleated filter cartridges are widely used in various industries, including woodworking, metalworking, food processing, pharmaceutical, and more. In woodworking, for instance, the extraction of sawdust and wood particles is essential not only for product quality but also for the safety and health of workers. In metalworking, the prevention of fine metal dust accumulation can minimize risks related to fire and explosion.

In food processing and pharmaceutical manufacturing, maintaining a clean and contaminant-free environment is critical. Dust extractor pleated filter cartridges help ensure compliance with stringent health and safety regulations while improving process efficiency.

Benefits of Using Pleated Filter Cartridges

dust extractor pleated filter cartridges

1. Increased Filtration Efficiency The enhanced surface area allows for superior filtration of smaller particles, ensuring cleaner air and a safer working environment.

2. Extended Filter Life Due to their high dust-holding capacity, pleated cartridges last longer than standard filters, reducing the frequency of replacements and maintenance costs.

3. Lower Energy Costs With less pressure drop, pleated filters require less energy to operate the dust extraction system, contributing to lower operational costs.

4. Versatility These cartridges can be manufactured with various media types, including polyester and polypropylene, allowing them to be tailored for specific applications depending on the nature of the dust or particles being collected.

5. Environmental Impact By optimizing the efficiency of dust extraction systems, pleated filter cartridges help minimize environmental contamination, contributing to sustainable industrial practices.

Maintenance and Care

To ensure optimal performance, regular maintenance and inspection of pleated filter cartridges are necessary. It is essential to monitor the pressure drop across the filter and adhere to the manufacturer's recommendations for replacement. Periodic cleaning and maintenance can further extend the lifespan of the cartridges, ensuring continued efficiency in dust extraction.

Conclusion

Dust extractor pleated filter cartridges are indispensable components in modern industrial dust collection systems. Their design and functionality enhance filtration efficiency, prolong service life, and reduce operating costs. In an era where workplace safety and environmental responsibility are of utmost importance, these cartridges serve not just as filters but as a crucial element in promoting health and safety across various industries. By investing in quality pleated filter cartridges, businesses can ensure a cleaner and safer environment for their employees and operations.

-

Will the activated carbon filter "vomit" pollutants after being used for a long time?NewsMay.15,2025

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

Email:

Email: