Tel:

+8615930870079

Tel:

+8615930870079

dec. . 14, 2024 06:19 Back to list

Antistatic Filter Elements for Enhanced Electrostatic Discharge Protection in Industrial Applications

Understanding Antistatic Filter Elements Importance and Applications

In various industrial and manufacturing settings, maintaining product quality and equipment longevity is crucial. One of the often-overlooked components in these processes is the antistatic filter element. Understanding what antistatic filter elements are, their significance, applications, and how they function can provide insights into their critical role in modern industries.

What are Antistatic Filter Elements?

Antistatic filter elements are specialized filters designed to minimize static electricity that can accumulate in dust and fume collection systems. Static electricity can be a significant hazard in many environments, particularly in industries that handle flammable materials or sensitive electronic components. These filter elements are engineered using materials that conduct static charges away, thereby preventing the buildup of electricity that could lead to accidents or equipment failure.

Importance of Antistatic Filter Elements

The importance of antistatic filter elements cannot be overstated. Static buildup in filtration systems can lead to several problems, including

1. Fire and Explosion Risks In environments where flammable dust or vapors are present, static discharges can ignite materials, leading to potentially catastrophic explosions. Antistatic filters help mitigate this risk by dissipating static electricity.

2. Equipment Damage Sensitive electronic components can easily be damaged by static discharges. By controlling static electricity, antistatic filter elements protect equipment and extend its operational life.

3. Improved Air Quality By effectively filtering out particulates while also preventing static buildup, these filter elements contribute to a cleaner and safer working environment.

4. Increased Efficiency When static is not properly managed, it can lead to performance issues in filtration systems, such as clogging or inconsistent airflow. Antistatic filters ensure optimal performance by maintaining an even flow and reducing downtime for maintenance.

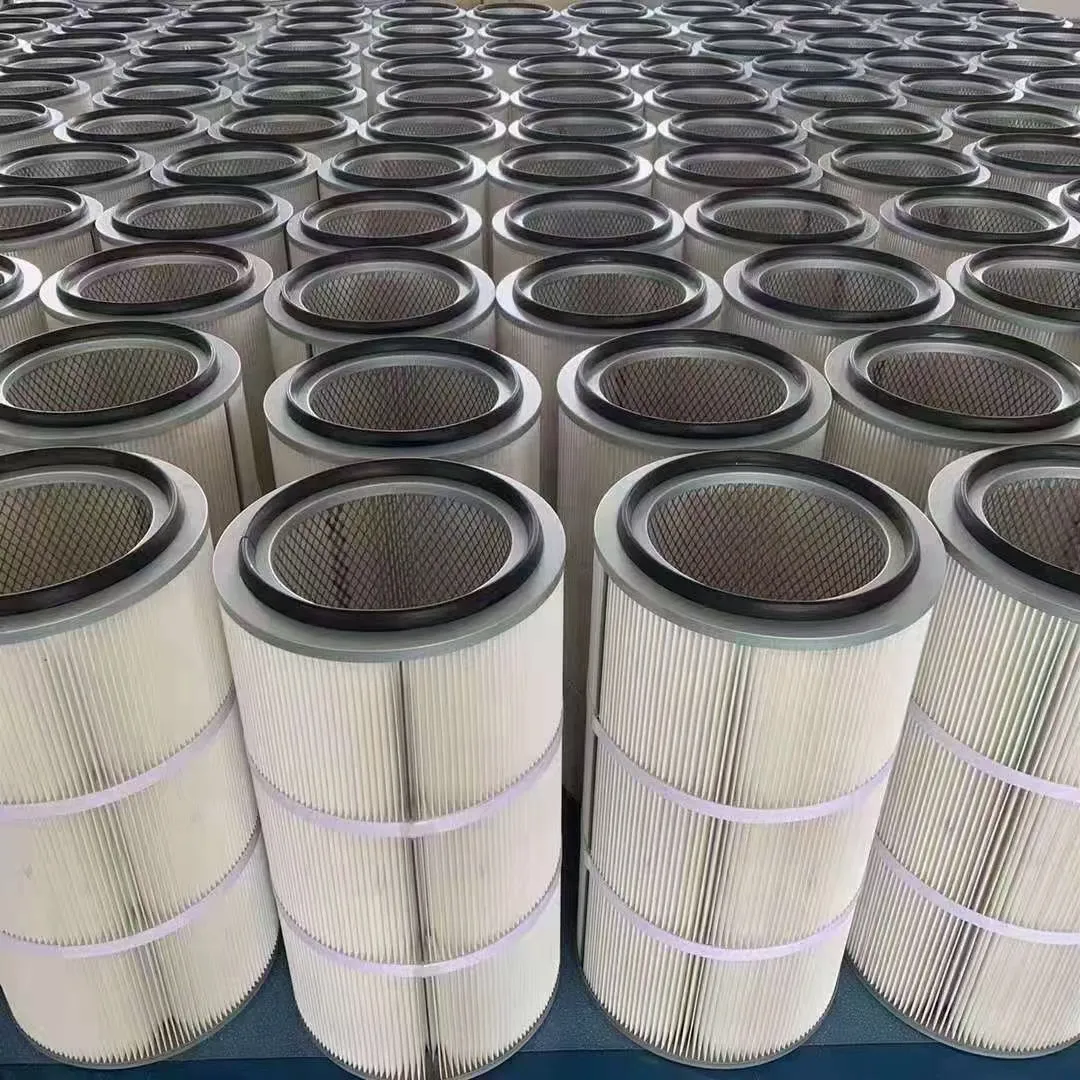

antistatic filter element

Applications of Antistatic Filter Elements

Antistatic filter elements are employed across various industries, including

1. Electronics Manufacturing In facilities that produce electronic components, the risk of electrostatic discharge (ESD) is particularly high. Antistatic filters are essential to ensure a safe environment and protect sensitive equipment.

2. Food Industry When processing food products, the presence of static electricity can affect both product quality and safety. Antistatic filters help keep the environment free from static charges that could interfere with production.

3. Pharmaceuticals Similar to the food industry, the pharmaceuticals sector must maintain stringent quality standards. Antistatic filter elements prevent contamination and protect sensitive processes from the dangers of static electricity.

4. Chemical Processing In industries dealing with flammable chemicals, static discharge can have severe consequences. Antistatic filters play a critical role in ensuring safe processing conditions.

5. Woodworking In wood processing facilities, dust from wood can accumulate and create static buildup. Antistatic filters help maintain safety and efficiency in these environments by controlling static charge.

Conclusion

In summary, antistatic filter elements are vital components in maintaining safety and efficiency across various industries. Their ability to mitigate the risks associated with static electricity can prevent accidents, protect sensitive equipment, and contribute to a healthier work environment. As industries continue to evolve, the importance of such specialized filtration systems cannot be underestimated. Investing in high-quality antistatic filters is not just an operational choice; it is a commitment to safety, quality, and efficiency in any workflow. Understanding and implementing these systems is essential for industries that prioritize reliability and safety in their operations.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: