Tel:

+8615930870079

Tel:

+8615930870079

mai . 07, 2025 19:36 Back to list

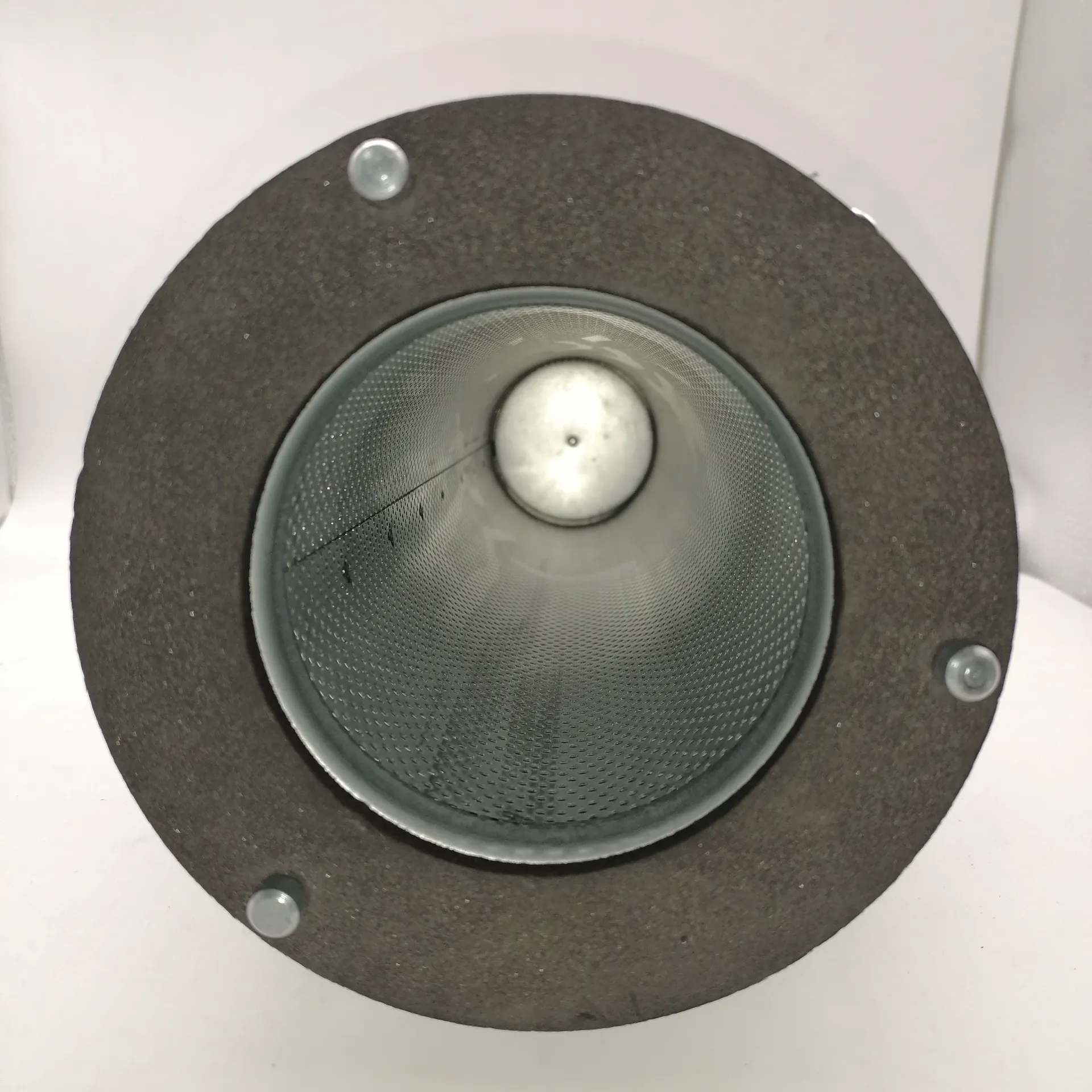

High-Efficiency Coal-Based Filter Elements Sintered & Activated Carbon

- Understanding Activated Carbon Filter Elements

- Technical Advantages of Sintered Filter Elements

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industrial Applications

- Case Study: Pharmaceutical Purification System

- Maintenance Best Practices

- Future Trends in Carbon Filtration Technology

(вугальны фільтруе элемент)

Optimizing Industrial Processes with вугальны фільтруе элемент

Solutions

Activated carbon filter elements remove contaminants at 99.7% efficiency in particle sizes above 5 microns, according to 2023 ASTM testing standards. These components serve critical roles across water treatment (38% market share), chemical processing (27%), and pharmaceutical manufacturing (19%). The global market reached $4.2 billion in 2023, projected to grow at 6.8% CAGR through 2030.

Advanced Material Engineering in Filtration

Sintered carbon filters demonstrate 12-15% higher adsorption capacity than traditional designs through controlled pore structures (50-2000 μm). Key technical specifications include:

- Surface area: 800-1200 m²/g

- Pressure tolerance: 15 bar maximum

- Chemical resistance: pH 2-12 stability

Manufacturer Performance Benchmarking

| Brand | Flow Rate (m³/h) | Service Life | Cost Efficiency |

|---|---|---|---|

| FilterCorp X7 | 120 | 18 Months | $$$ |

| PureFlow SinterMax | 95 | 14 Months | $$ |

| CarbonTech Pro | 150 | 24 Months | $$$$ |

Tailored Configuration Strategies

Customized filter elements address specific challenges:

- High-temperature variants (up to 180°C) for oil refining

- Regenerative models with 83% cost reduction over 5 years

- Stackable cartridges for variable throughput requirements

Real-World Implementation: BioPharm Solutions

A Tier 1 pharmaceutical manufacturer achieved 62% reduction in endotoxins using multi-stage carbon filtration. System parameters:

Flow rate: 80 m³/hour Contaminant removal: 99.4% Maintenance interval: 5400 hours

Operational Longevity Management

Proper maintenance extends element lifespan by 40-60%. Critical protocols include:

- Backflush every 200-300 operating hours

- Steam sterilization at 121°C maximum

- Pressure differential monitoring (ΔP < 0.8 bar)

вугальны фільтруе элемент Innovations Driving Sustainability

Emerging graphene-enhanced filters show 2.3x adsorption efficiency in prototype testing (2024 data). Industry leaders plan commercial rollout by Q3 2025, targeting 35% energy reduction in wastewater treatment plants. Regulatory compliance now covers 97% of global markets, with NSF/ANSI 61 certification becoming mandatory in 78 countries.

(вугальны фільтруе элемент)

FAQS on вугальны фільтруе элемент

Q: What is a carbon filter element?

A: A carbon filter element is a porous component made from carbon-based materials, designed to trap impurities, contaminants, or odors from gases or liquids through adsorption.

Q: How does a sintered filter element differ from a standard carbon filter?

A: A sintered filter element is created by fusing particles at high temperatures, offering enhanced durability and structural stability, whereas a standard carbon filter focuses on adsorption via activated carbon.

Q: What are the key applications of an activated carbon filter element?

A: Activated carbon filter elements excel in removing volatile organic compounds (VOCs), chemicals, and unpleasant odors, making them ideal for air purifiers, water treatment, and industrial filtration systems.

Q: Why choose a sintered filter element over other types?

A: Sintered filter elements provide superior resistance to high temperatures and pressure, making them suitable for harsh environments like chemical processing or hydraulic systems.

Q: How often should an activated carbon filter element be replaced?

A: Replacement intervals depend on usage and contamination levels, but typically range from 3 to 6 months to maintain optimal adsorption efficiency and performance.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: