ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Fev . 08, 2025 08:05 Back to list

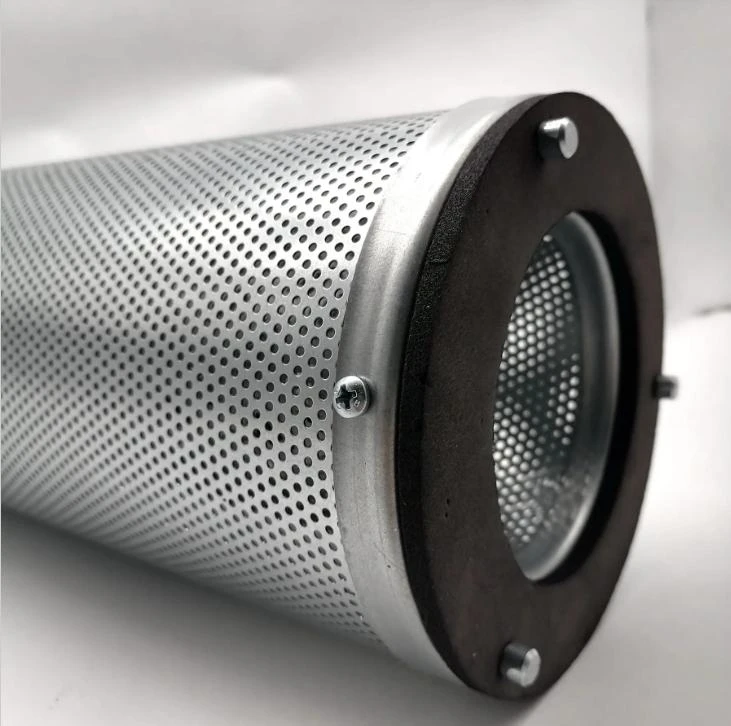

Polyester Air Filter Cartridge

Within the realms of industrial filtration, the silo filter cartridge emerges as a pivotal component, ensuring optimal functionality and longevity of large-scale silos. Known for its robust construction and exceptional filtration capabilities, this product is indispensable for industries reliant on storage and movement of fine particulates, powders, and granular materials. The effectiveness of silo filter cartridges isn’t just theoretical; experienced professionals across various sectors have consistently lauded their superior performance, ease of maintenance, and significant role in operational efficiency.

In terms of trustworthiness, manufacturers of silo filter cartridges ensure rigorous testing and quality assurance processes. It’s not uncommon for these products to undergo numerous stages of quality checks, including simulations of extreme working conditions and analysis of long-term performance data. Clients in industries such as agriculture, pharmaceuticals, and construction make purchasing decisions based on these stringent validations, understanding that their choice directly influences both operational success and compliance with safety standards. One of the real-world experiences that highlights the practicality of silo filter cartridges involves a mid-sized food processing plant that faced challenges in managing flour dust emissions. By transitioning to high-efficiency silo filter cartridges, the plant not only saw a marked reduction in emissions but also experienced lower energy consumption. The reduced strain on the facility's ventilation systems exemplifies the cost-saving benefits achieved alongside enhanced air quality. Another example can be drawn from the cement manufacturing sector, where fine dust is notoriously difficult to manage. By integrating silo filter cartridges designed specifically for high dust retention, companies have reported not only improved air quality within their production facilities but also a significant decrease in machinery wear and tear, underscoring the role of these cartridges in prolonging equipment life. In conclusion, the silo filter cartridge serves as more than just a filtration component; it is a critical driver of operational excellence and sustainability. Its design, backed by expert research and industry experiences, positions it as an authoritative solution for managing industrial emissions. As industries continue to evolve in an age of heightened environmental consciousness and regulation, the role of such well-engineered products will continue to expand, proving indispensable to both economic and environmental objectives. By choosing the right silo filter cartridges, businesses not only optimize their operations but also set a benchmark for safety and ecological responsibility in the industry.

In terms of trustworthiness, manufacturers of silo filter cartridges ensure rigorous testing and quality assurance processes. It’s not uncommon for these products to undergo numerous stages of quality checks, including simulations of extreme working conditions and analysis of long-term performance data. Clients in industries such as agriculture, pharmaceuticals, and construction make purchasing decisions based on these stringent validations, understanding that their choice directly influences both operational success and compliance with safety standards. One of the real-world experiences that highlights the practicality of silo filter cartridges involves a mid-sized food processing plant that faced challenges in managing flour dust emissions. By transitioning to high-efficiency silo filter cartridges, the plant not only saw a marked reduction in emissions but also experienced lower energy consumption. The reduced strain on the facility's ventilation systems exemplifies the cost-saving benefits achieved alongside enhanced air quality. Another example can be drawn from the cement manufacturing sector, where fine dust is notoriously difficult to manage. By integrating silo filter cartridges designed specifically for high dust retention, companies have reported not only improved air quality within their production facilities but also a significant decrease in machinery wear and tear, underscoring the role of these cartridges in prolonging equipment life. In conclusion, the silo filter cartridge serves as more than just a filtration component; it is a critical driver of operational excellence and sustainability. Its design, backed by expert research and industry experiences, positions it as an authoritative solution for managing industrial emissions. As industries continue to evolve in an age of heightened environmental consciousness and regulation, the role of such well-engineered products will continue to expand, proving indispensable to both economic and environmental objectives. By choosing the right silo filter cartridges, businesses not only optimize their operations but also set a benchmark for safety and ecological responsibility in the industry.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: