Tel:

+8615930870079

Tel:

+8615930870079

Dez . 16, 2024 00:58 Back to list

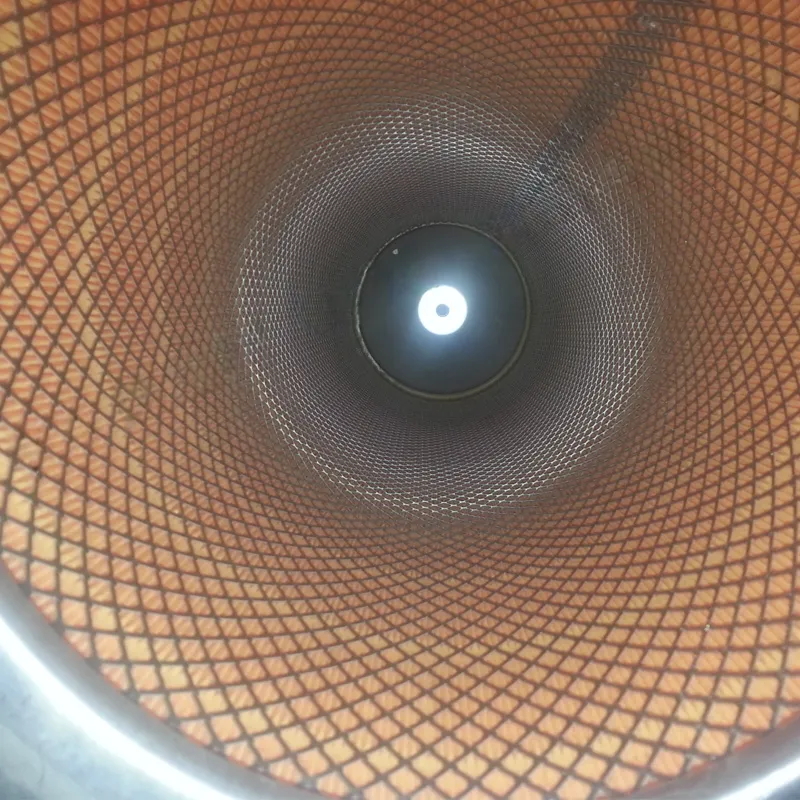

gas turbine inlet filter

The Importance of Gas Turbine Inlet Filters

Gas turbines are a critical component in various industries, including power generation, aviation, and oil and gas. Their efficiency and performance are heavily influenced by numerous factors, one of the most significant being the quality of the air entering the turbine. This makes gas turbine inlet filters an essential element in maintaining the operational integrity and longevity of gas turbines.

Understanding Inlet Filters

Gas turbine inlet filters are designed to remove particulates and contaminants from the air before it enters the turbine. These filters serve a vital purpose, as even the smallest particles can compromise the performance and efficiency of a gas turbine. Inlet air can contain dust, pollen, sand, salt, and other airborne contaminants, depending on the geographical location and environmental conditions. Without adequate filtration, these substances can lead to several issues, including erosion, corrosion, and reduced efficiency.

Types of Gas Turbine Inlet Filters

There are several types of filters used in gas turbine applications, each designed for different environments and operational requirements. The most common types include

1. Panel Filters These are often used in lighter-duty applications and are designed to capture larger particles. They typically consist of a framework of materials such as fiberglass or polyester, which are effective in capturing particulate matter.

2. Bag Filters Known for their high dirt-holding capacity, bag filters can capture a wide range of particle sizes. They are often used in environments with high levels of airborne contaminants and can be engineered to have different levels of filtration efficiency.

3. Ducted Inlet Filters These systems are typically custom-designed to fit specific turbine configurations. They consist of multiple filter sections and can offer high filtration efficiency, protecting the turbine from fine dust and other contaminants.

4. Self-Cleaning Filters These innovative systems utilize a combination of mechanisms to clean the filter media automatically, ensuring optimal airflow and filter performance without the need for frequent manual maintenance.

gas turbine inlet filter

Benefits of Gas Turbine Inlet Filters

Investing in high-quality inlet filters offers several advantages

- Improved Efficiency Clean air enhances the combustion process, allowing gas turbines to operate more efficiently. This can lead to increased power output and reduced fuel consumption.

- Extended Turbine Life By filtering out damaging particulates, inlet filters help protect turbine components from wear and tear, extending their operational lifespan and reducing maintenance costs.

- Reliability Gas turbines in environments prone to extreme weather or dust storms can suffer performance degradation if not properly protected. Quality inlet filters ensure a steady supply of clean air, enhancing the reliability of the turbine.

- Compliance with Standards Many industries are subject to strict environmental regulations. Effective air filtration helps ensure compliance with these standards, reducing the risk of fines and enhancing the company’s reputation for environmental responsibility.

Challenges and Considerations

While gas turbine inlet filters are crucial, selecting the appropriate system can be challenging. Factors to consider include the specific application, the environment in which the turbine operates, the expected levels of contaminants, and the filter’s maintenance requirements. Regular monitoring and maintenance of these filters are also essential to ensure optimal performance. Clogged filters can lead to increased pressure drops, decreasing the efficiency of airflow and potentially causing operational issues.

Conclusion

Gas turbine inlet filters play an indispensable role in ensuring the efficiency and reliability of gas turbines across various industries. By investing in quality filtration systems and adopting regular maintenance practices, operators can safeguard their turbines against contaminants, leading to improved performance and reduced operational costs. As industries continue to evolve and demand more from their gas turbine technology, the importance of effective inlet filtration will only continue to grow, reinforcing its necessity in modern energy and propulsion systems.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: