Tel:

+8615930870079

Tel:

+8615930870079

Out . 04, 2024 02:24 Back to list

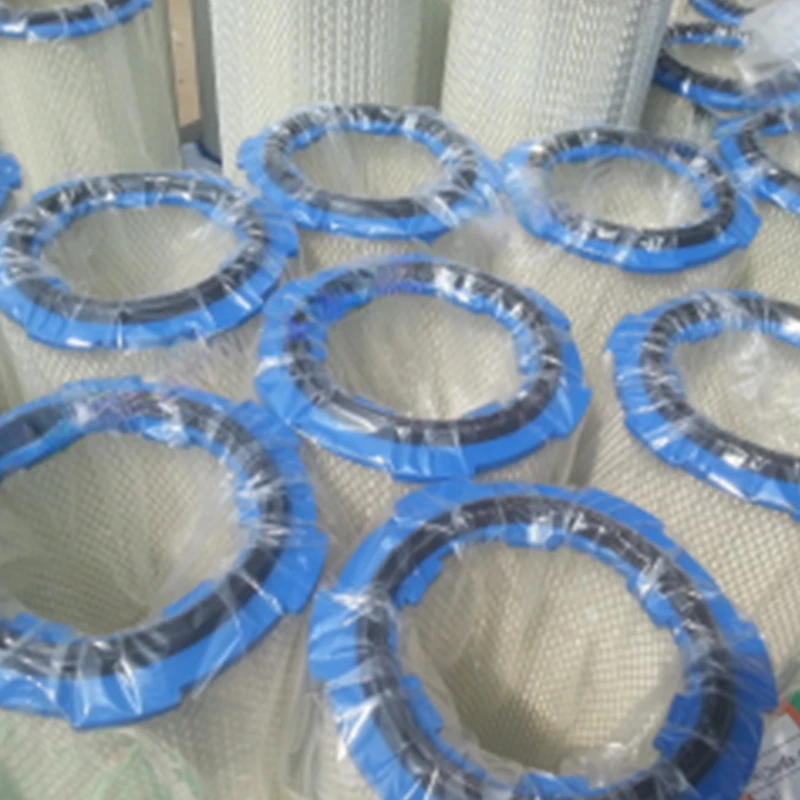

dust extractor pleated filter cartridges

Understanding Dust Extractor Pleated Filter Cartridges

In various industrial settings, maintaining a clean and safe work environment is crucial. Dust extractor systems play an essential role in this process by removing harmful airborne particles from the air. One of the significant components of these systems is the pleated filter cartridge, which is designed to enhance filtration efficiency and reduce equipment maintenance.

Pleated filter cartridges are engineered with a series of folds or pleats, increasing the surface area available for capturing dust and particulates. This unique design allows for a higher dust-holding capacity compared to traditional flat filters. As a result, operators can enjoy longer intervals between filter replacements, minimizing downtime and operational costs. The efficiency of these cartridges is particularly critical in industries such as pharmaceuticals, food processing, woodworking, and metalworking, where cleanliness is paramount.

The materials used in pleated filter cartridges are versatile, often made from synthetic fibers or cellulose, which can be treated to enhance their dust-holding capabilities. Additionally, they can come with different coatings to repel moisture or resist chemicals, making them suitable for various applications. This adaptability allows industries to choose the ideal filter cartridge based on their specific needs, optimizing performance and ensuring compliance with air quality regulations.

dust extractor pleated filter cartridges

One significant advantage of using pleated filter cartridges in dust extractors is their improved airflow. The increased surface area allows air to flow through the filter more freely, decreasing the resistance within the system. This improved airflow means that dust extractors can operate more efficiently, leading to energy savings and better overall performance. Additionally, with less strain on the equipment, there is a reduced risk of breakdown, extending the lifespan of both the filter and the dust extractor itself.

Another essential aspect to consider is the ease of installation and replacement. Most pleated filter cartridges are designed for quick and simple exchanges, allowing maintenance personnel to change filters without extensive downtime or complex procedures. This feature is particularly beneficial in high-demand environments where every hour of operation is valuable.

In summary, dust extractor pleated filter cartridges play a vital role in ensuring clean air in various industrial workplaces. Their design increases dust-holding capacity, improves airflow, and enhances the efficiency of dust extraction systems. By investing in high-quality pleated filter cartridges, industries can maintain compliance with health and safety regulations, promote employee well-being, and ultimately improve their productivity. As environmental concerns continue to rise, incorporating advanced filtration technology like pleated filter cartridges will become even more crucial in the quest for cleaner air.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: