ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Fev . 15, 2025 00:46 Back to list

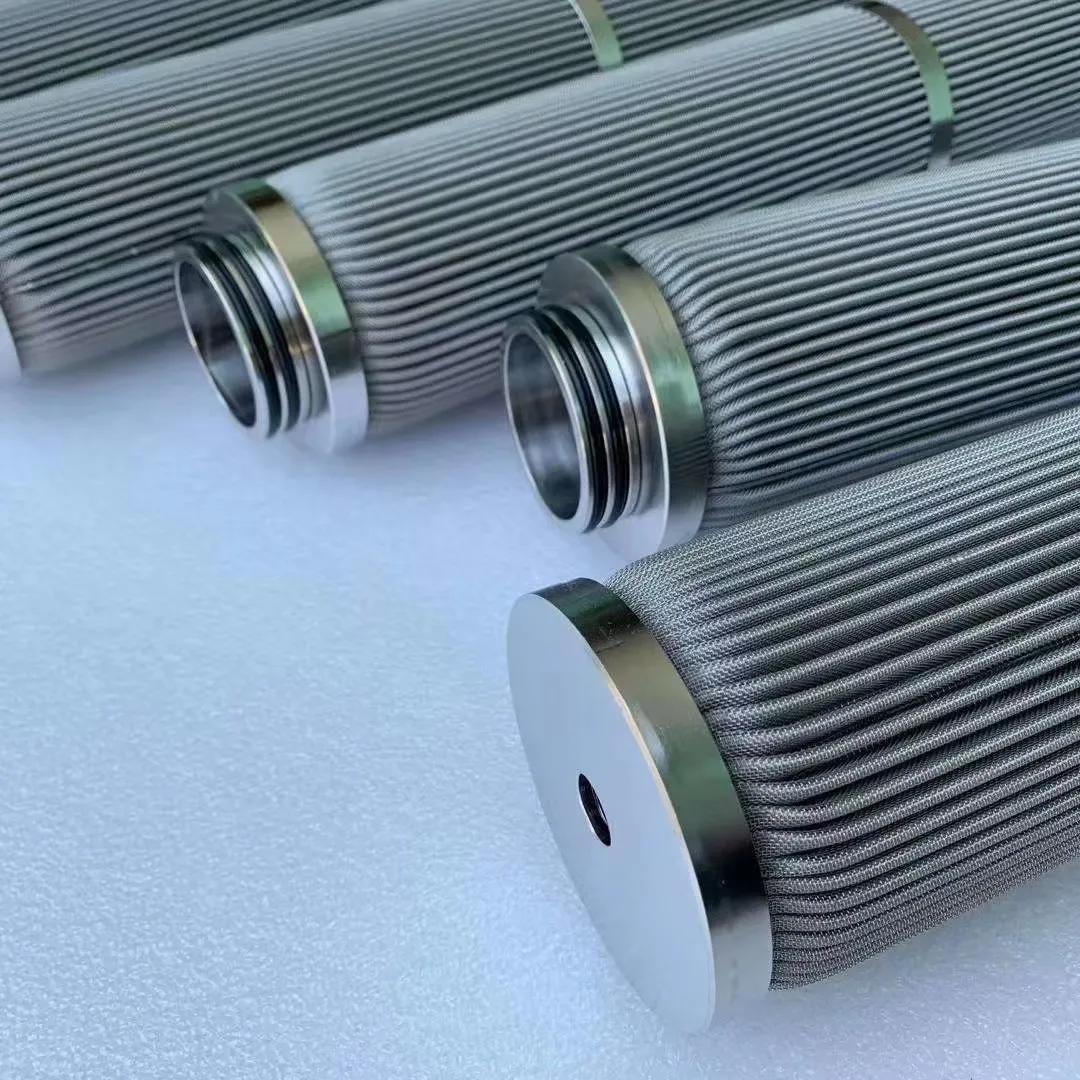

dust collector pleated filter

Dust collectors play a critical role in maintaining a clean and efficient work environment, particularly in industrial settings where managing air quality is paramount. Among the many components that determine the effectiveness of a dust collector, pleated filters stand out due to their unmatched performance and versatility. As someone deeply entrenched in the industry, I've encountered pleated filters in various applications and have observed their impact on operational efficiency and air quality control.

A strong grasp of industry standards is also crucial when it comes to pleated filter application. Adherence to guidelines such as those set by the Occupational Safety and Health Administration (OSHA) or the Environmental Protection Agency (EPA) ensures compliance and enhances the credibility of a business. Companies that prioritize investing in high-quality pleated filters not only protect their workforce from harmful air pollutants but also bolster their reputation as environmentally responsible entities. From an authoritative standpoint, the benefits of pleated filters are well-documented in various industry journals and case studies. Through these reports, industry leaders have consistently validated the efficacy of pleated filters in improving air quality and reducing operational costs. As methodologies and technologies continue to evolve, pleated filters are expected to integrate even more advanced features, such as self-cleaning mechanisms or IoT capabilities that provide real-time updates on their condition. Trustworthiness is also key when sourcing pleated filters. Ensuring that these components are purchased from reputable manufacturers with a track record for reliability can make a substantial difference. Companies should seek out suppliers with rigorous quality control processes and a commitment to excellence to guarantee the longevity and performance of the filters. In conclusion, pleated filters are an indispensable component of dust collection systems that significantly enhance air filtration capabilities. Their compact design, high efficiency, and cost-saving potential make them an ideal choice for businesses aiming to maintain high standards of air purity while optimizing operational efficiencies. Whether you’re considering switching from traditional options or refining your existing setup, pleated filters offer a robust and reliable solution to your dust management needs.

A strong grasp of industry standards is also crucial when it comes to pleated filter application. Adherence to guidelines such as those set by the Occupational Safety and Health Administration (OSHA) or the Environmental Protection Agency (EPA) ensures compliance and enhances the credibility of a business. Companies that prioritize investing in high-quality pleated filters not only protect their workforce from harmful air pollutants but also bolster their reputation as environmentally responsible entities. From an authoritative standpoint, the benefits of pleated filters are well-documented in various industry journals and case studies. Through these reports, industry leaders have consistently validated the efficacy of pleated filters in improving air quality and reducing operational costs. As methodologies and technologies continue to evolve, pleated filters are expected to integrate even more advanced features, such as self-cleaning mechanisms or IoT capabilities that provide real-time updates on their condition. Trustworthiness is also key when sourcing pleated filters. Ensuring that these components are purchased from reputable manufacturers with a track record for reliability can make a substantial difference. Companies should seek out suppliers with rigorous quality control processes and a commitment to excellence to guarantee the longevity and performance of the filters. In conclusion, pleated filters are an indispensable component of dust collection systems that significantly enhance air filtration capabilities. Their compact design, high efficiency, and cost-saving potential make them an ideal choice for businesses aiming to maintain high standards of air purity while optimizing operational efficiencies. Whether you’re considering switching from traditional options or refining your existing setup, pleated filters offer a robust and reliable solution to your dust management needs.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: