Tel:

+8615930870079

Tel:

+8615930870079

Set . 07, 2024 03:17 Back to list

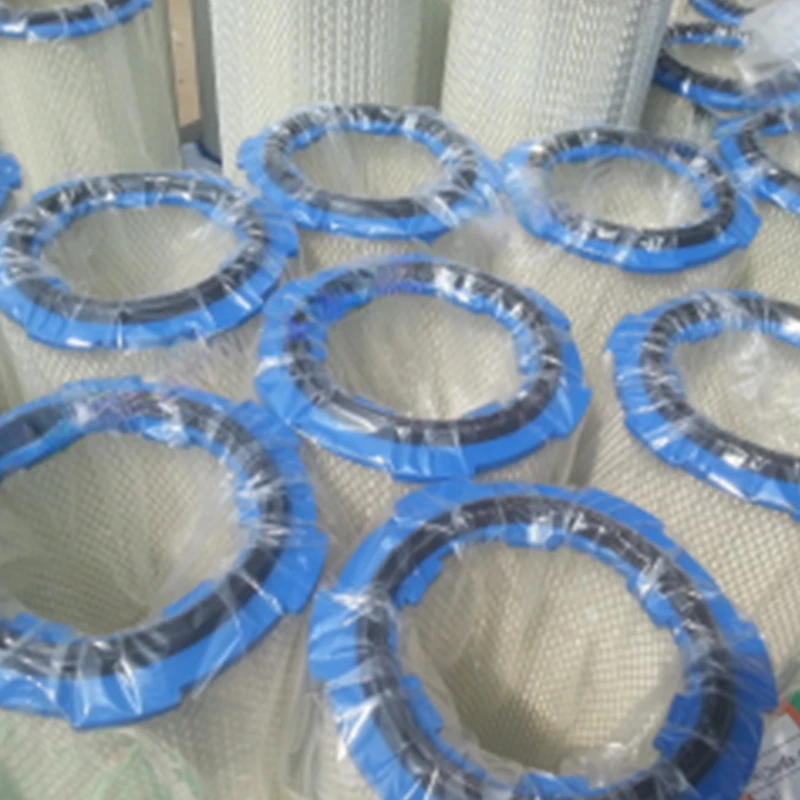

High-Performance Dust Extractor Cartridge Filters for Superior Air Quality

Understanding Dust Extractor Cartridge Filters Essential for Clean and Safe Work Environments

Dust extractor cartridge filters are critical components in maintaining clean air quality in various industrial and commercial settings. These filters play an integral role in dust collection systems, which are essential for protecting both worker health and machinery efficiency. This article explores the functionality, types, and benefits of using cartridge filters in dust extraction systems.

What is a Dust Extractor Cartridge Filter?

A dust extractor cartridge filter is designed to capture and retain fine particulate matter, including dust, dirt, and other airborne contaminants. Typically cylindrical in shape, these filters are constructed from a variety of materials, including pleated polyester and fibrous media. Their unique design maximizes surface area, allowing them to trap more dust while maintaining airflow efficiency. The pleated structure also enables them to handle large volumes of dust over extended periods.

How Do Cartridge Filters Work?

Dust extractor systems equipped with cartridge filters operate through a simple yet efficient process. Air laden with dust enters the system and passes through the cartridge filter. The filter's material traps the dust particles while allowing clean air to flow through. As the filtration process continues, dust accumulates on the surface of the filter. Periodic cleaning is necessary to maintain efficiency; many systems utilize a reverse air jet or pulse cleaning mechanism to dislodge the accumulated dust, ensuring optimal performance.

Types of Cartridge Filters

dust extractor cartridge filter

Cartridge filters come in various types, tailored for specific applications and dust types. Common filters include

1. Pleated Filters These are designed with multiple folds, increasing surface area and dust retention capacity. 2. High-Efficiency Particulate Air (HEPA) Filters These capture 99.97% of particles that are 0.3 microns or larger, making them suitable for environments requiring the highest air quality standards. 3. Activated Carbon Filters These are specially designed to remove odors and volatile organic compounds (VOCs) in addition to dust particles.

Benefits of Using Dust Extractor Cartridge Filters

1. Improved Air Quality By effectively removing airborne contaminants, these filters significantly enhance indoor air quality, thus reducing health risks associated with dust inhalation. 2. Increased Equipment Longevity Dust can cause wear and tear on machinery. By keeping workspaces cleaner, cartridge filters help extend the life of equipment and reduce maintenance costs. 3. Compliance with Regulations Many industries are subject to strict air quality regulations. Utilizing efficient dust extraction systems helps companies comply with these standards. 4. Energy Efficiency Well-maintained cartridge filters operate efficiently, reducing energy consumption and overall operational costs.

Conclusion

Dust extractor cartridge filters are indispensable in various settings where dust and airborne contaminants pose a threat to health and productivity. By understanding their function, types, and benefits, businesses can make informed decisions about their dust collection needs. Investing in high-quality cartridge filters not only promotes a cleaner environment but also supports the long-term efficiency of both personnel and machinery. As industries continue to prioritize workplace safety and regulatory compliance, understanding and utilizing effective dust extraction solutions will remain a crucial aspect of operational practices.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: