Tel:

+8615930870079

Tel:

+8615930870079

Out . 10, 2024 02:07 Back to list

Air Filtration System for Enhanced Turbine Performance and Efficiency Improvements

The Importance of Air Filter Turbines in Modern Engineering

In the realm of modern engineering, air filter turbines are becoming increasingly crucial in various applications ranging from industrial manufacturing to clean energy production. These innovative devices serve a dual purpose improving air quality while enhancing operational efficiencies. With growing awareness of environmental issues and stricter regulations on emissions, the demand for advanced air filtration solutions has spurred innovation in turbine technology.

Air filter turbines function by integrating filtration systems directly into turbine operations. This integration not only improves the quality of air but also enhances the overall performance of the turbine. At their core, these systems work by drawing in ambient air, which passes through sophisticated filter mediums designed to capture particulate matter, pollutants, and contaminants. Once the air is sufficiently cleaned, it continues into the turbine, resulting in a more efficient energy conversion process.

One of the significant benefits of using air filter turbines is the reduction of environmental pollutants. In many industrial processes, airborne pollutants can be a major issue, contributing to poor air quality and health hazards. By using air filter turbines, industries can minimize their carbon footprint while adhering to environmental regulations. This translates to cleaner air in urban areas, ultimately benefiting public health and the environment.

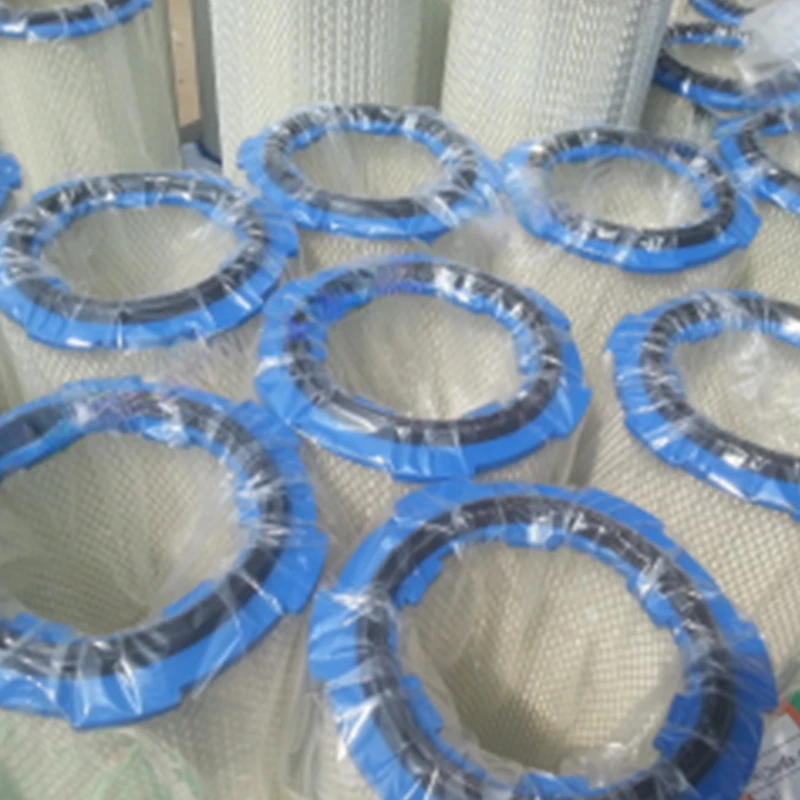

air filter turbine

Moreover, air filter turbines have applications in the renewable energy sector, particularly in wind energy. Wind turbines equipped with advanced air filtration systems can operate more efficiently by maintaining optimal airflow and reducing wear on components. This not only prolongs the lifespan of the turbines but also maximizes energy output, making them more economically viable for operators.

In addition to their environmental advantages, air filter turbines can also lead to significant economic benefits. By improving the efficiency of energy conversion processes, these systems can reduce operational costs for businesses. For example, many manufacturing plants rely on large turbines for power, and integrating air filter technology can enhance their productivity, leading to increased profitability over time.

Furthermore, the consistent advancement in filtration technology is making these systems increasingly effective. Recent innovations have led to the development of more durable and efficient materials that can capture smaller particles and withstand higher temperatures. These improvements not only enhance the performance of air filter turbines but also make them more adaptable to a variety of industrial conditions.

In conclusion, air filter turbines represent a significant advancement in engineering that addresses critical environmental and operational challenges. As industries continue to seek sustainable solutions, the integration of air filtration in turbine technology will play an essential role in promoting cleaner air and enhancing energy efficiency. With ongoing research and development, the future holds great potential for these systems to revolutionize both industrial processes and the broader energy landscape. The commitment to innovation in air filter turbine technology is not merely an option; it is a necessity for achieving a sustainable future.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: