Tel:

+8615930870079

Tel:

+8615930870079

paź . 12, 2024 14:27 Back to list

Choosing the Right Vacuum Filter Cartridge for Your Needs and Applications

Understanding Vacuum Filter Cartridges A Comprehensive Overview

In the realm of industrial filtration, vacuum filter cartridges play a crucial role, serving a wide array of applications across varying sectors. These specialized components are designed to separate solid particles from liquids, ensuring that processes run smoothly and efficiently. To understand their significance, we must delve into what vacuum filter cartridges are, how they operate, and the advantages they offer.

What is a Vacuum Filter Cartridge?

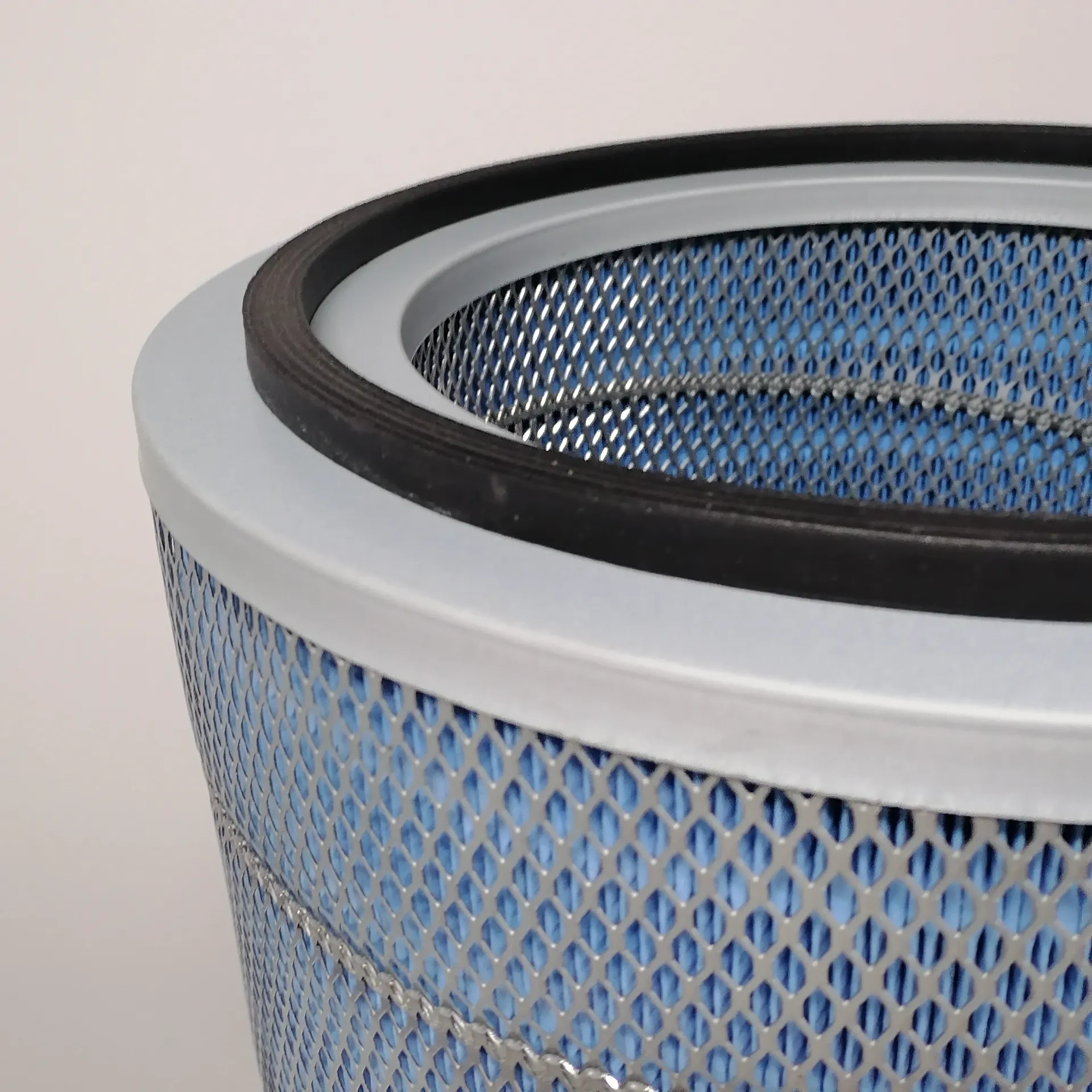

A vacuum filter cartridge is a filtration device that utilizes vacuum pressure to draw liquid through a permeable medium, effectively trapping solid particles. The design typically consists of a cylindrical or tubular structure filled with a filter medium, which could be made from different materials, including polypropylene, nylon, or cellulose. As the vacuum is created, the liquid passes through the cartridge, leaving behind contaminants, thus purifying the liquid.

How Do Vacuum Filter Cartridges Work?

The operation of a vacuum filter cartridge relies on the principles of both vacuum pressure and surface area. When the vacuum is applied, it creates a pressure differential that forces the liquid to move through the filter media. The design of the cartridge is such that it maximizes the surface area for contact with the liquid, which in turn enhances filtration efficiency.

Once the liquid enters the cartridge, it encounters a filtration medium that captures particles of various sizes, depending on the specifications of the material used. The filtrate, or cleaned liquid, exits the cartridge, while the retained solids form a cake on the surface of the filter media. Over time, this cake can build up and may require periodic cleaning or replacement of the cartridge to maintain optimal performance.

Applications of Vacuum Filter Cartridges

Vacuum filter cartridges are widely used in numerous industries, including

2. Pharmaceuticals The pharmaceutical sector relies on vacuum filter cartridges to ensure that active ingredients remain uncontaminated during the manufacturing process.

vacuum filter cartridge

3. Chemicals In chemical processing, these filters help in the separation of catalysts and other solid particulates from liquid streams.

4. Water Treatment They are also essential in municipal water treatment plants, where they play a significant role in ensuring clean and safe drinking water.

Advantages of Vacuum Filter Cartridges

Vacuum filter cartridges offer several advantages that make them a preferred choice in filtration processes

1. Efficiency The vacuum-driven process enhances the speed of filtration, allowing for higher flow rates compared to gravity-fed systems.

2. Versatility These cartridges can be customized with different filter media to cater to specific particle sizes and types, making them adaptable to various applications.

3. Compact Design The cylindrical design of vacuum filter cartridges allows for a substantial surface area in a compact unit, making them easy to fit into existing systems without requiring significant alterations.

4. Reduced Maintenance Since these cartridges are engineered to handle varying degrees of solids and liquids, they often require less frequent maintenance, which is critical for continuous production environments.

5. Environmental Impact By effectively removing solids from liquids, vacuum filter cartridges contribute to reducing waste and promoting sustainable practices in industrial operations.

Conclusion

In summary, vacuum filter cartridges are indispensable components in modern industrial filtration systems. Their ability to efficiently separate solids from liquids across various sectors underlines their importance and effectiveness. As industries continue to prioritize efficiency, safety, and sustainability, understanding and utilizing vacuum filter cartridges will remain crucial in meeting these goals. Whether for food processing, pharmaceutical production, or chemical manufacturing, the role of vacuum filter cartridges is undoubtedly significant in advancing filtration technology and practices. As we look toward the future, ongoing innovations and improvements in filter designs will likely enhance their efficiency and broaden their application scope even further.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: