Tel:

+8615930870079

Tel:

+8615930870079

wrz . 11, 2024 07:47 Back to list

High-Quality Sintered Metal Filter Cartridges for Efficient Filtration

The Advantages of Sintered Metal Filter Cartridges

Sintered metal filter cartridges have emerged as a crucial component in various industrial filtration applications, owing to their superior performance, durability, and versatility. These filters are crafted through a process known as sintering, which involves compacting and heating powdered metal to form a porous structure that effectively captures particles while allowing fluids to flow freely.

One of the primary advantages of sintered metal filter cartridges is their remarkable durability. Unlike traditional filter materials such as paper or cloth, which can degrade over time, sintered metal filters display exceptional resistance to mechanical stress, high temperatures, and corrosive chemicals. This resilience makes them ideal for demanding applications in industries such as oil and gas, pharmaceuticals, food and beverage, and water treatment.

Moreover, sintered metal filters boast a high filtration efficiency and precision. The sintering process creates a uniform pore structure that can be tailored to specific filtration requirements. This allows for effective removal of particulates ranging from coarse contaminants to fine particles, ensuring that the liquid or gas being filtered meets stringent quality standards. Additionally, the ability to precisely control the pore size means that businesses can customize filters to suit their unique application needs.

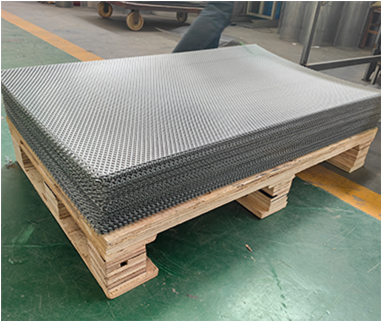

sintered metal filter cartridge

Another significant benefit of sintered metal filter cartridges is their ease of cleaning and reusability. Many filtration systems require regular replacement of their filter elements, leading to increased operational costs and waste. In contrast, sintered metal filters can be easily cleaned using various methods, including ultrasonic cleaning, backwashing, or chemical cleaning. This reusability not only reduces costs but also minimizes environmental impact by lessening waste generation.

Sintered metal filters also excel in high-pressure applications. Their robust construction allows them to withstand considerable pressure differentials without compromising their structural integrity. This property makes them particularly suited for applications like hydraulic systems, where reliable and safe performance is critical.

The use of sintered metal filter cartridges can also enhance operational efficiency. With a stable and consistent filtration performance, these filters help maintain optimal process conditions, reducing the risk of downtime due to clogging or failure. Furthermore, their durability means that businesses can operate with reduced maintenance intervals, allowing for more productive use of time and resources.

In conclusion, sintered metal filter cartridges offer a wealth of advantages for a variety of industries, including durability, high filtration efficiency, ease of cleaning, high-pressure resilience, and operational efficiency. As technology continues to advance, the applications of these innovative filtration solutions will expand even further, promising a cleaner, more efficient future for industrial processes. Investing in sintered metal filter cartridges can thus prove to be a savvy decision for businesses looking to enhance their filtration practices while managing costs and reducing their environmental footprint.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: