Tel:

+8618931101301

Tel:

+8618931101301

lis . 07, 2024 18:40 Back to list

Exploring the Benefits of Metal Filter Elements in Industrial Applications

Understanding Metal Filter Elements Key Characteristics and Applications

Metal filter elements have become essential components in various industrial processes, particularly where the filtration of particulates and contaminants is crucial for maintaining product quality and operational efficiency. This article delves into the characteristics, manufacturing techniques, benefits, and applications of metal filter elements, providing insight into their importance in modern engineering.

What are Metal Filter Elements?

Metal filter elements are devices designed to remove unwanted particles from gases or liquids. Made primarily from metals such as stainless steel, titanium, or aluminum, these filters can withstand high temperatures, aggressive chemicals, and extensive operational demands. Unlike their polymeric or ceramic counterparts, metal filter elements offer superior durability and longevity, making them ideal for harsh industrial environments.

Key Characteristics

1. High Temperature Resistance One of the standout features of metal filter elements is their ability to perform in extreme temperatures. This resistance is vital in applications such as aerospace and automotive industries, where materials are often exposed to considerable heat.

2. Corrosion Resistance Metal filters are engineered to resist corrosive substances, making them suitable for chemical processing and oil refining. For instance, stainless steel filters can withstand acidic or basic solutions without degrading, ensuring consistent performance over time.

3. Filtration Precision Metal filter elements can achieve fine filtration with precise pore sizes, effectively trapping microscopic particles and ensuring product purity. This precision is crucial in industries such as pharmaceuticals and food processing, where contaminants can compromise safety and effectiveness.

4. Washable and Reusable One of the significant advantages of metal filter elements is their ability to be cleaned and reused. Unlike disposable filters, metal filters can be backwashed or chemically cleaned, which reduces waste and operational costs over time.

5. Customization and Versatility Metal filter elements can be tailored to specific requirements, such as size, shape, and filtration efficiency. This versatility makes them applicable in a wide range of industries and processes, from water treatment systems to HVAC applications.

Manufacturing Techniques

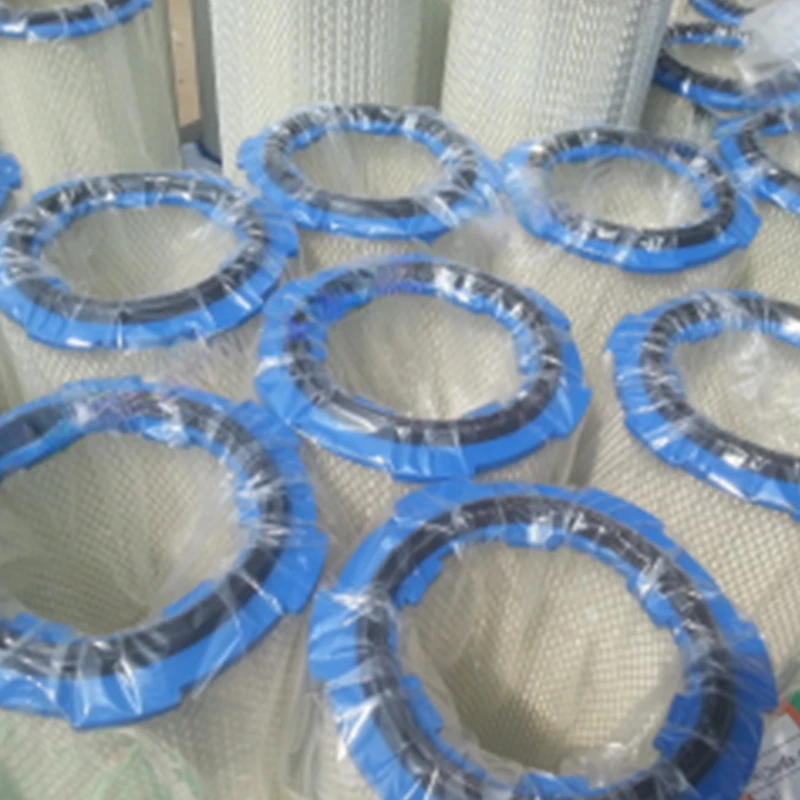

metal filter element

The production of metal filter elements involves several advanced manufacturing techniques

. These may include- Sintering This process involves compacting metal powders and heating them to create a solid structure. Sintered filters provide excellent filtration capabilities and structural integrity. - Welding Metal filter elements can be constructed through various welding techniques, allowing for complex geometries and robust designs that enhance performance. - Laser Cutting High-precision laser cutting enables the creation of intricate patterns and pore structures, optimizing filtration efficiency while minimizing flow resistance.

Applications

Metal filter elements find applications across diverse industries. Key sectors include

1. Chemical Processing In chemical manufacturing, metal filters separate suspended solids from liquids, ensuring that processing equipment operates efficiently and contamination risks are minimized.

2. Automotive Industry Metal filters play an important role in engine systems, including fuel and oil filtration, where they prevent particulates from damaging sensitive components.

3. Aerospace The aerospace sector utilizes metal filters in hydraulic systems and fuel systems, where reliability and performance under extreme conditions are paramount.

4. Pharmaceuticals In the pharmaceutical industry, metal filter elements ensure sterile environments by removing potential contaminants from liquids and gases used in production.

5. Water Treatment Metal filters are employed in various water purification processes, effectively removing sediments, parasites, and other impurities to produce safe drinking water.

Conclusion

Metal filter elements are invaluable assets in countless industrial applications due to their durability, efficiency, and adaptability. As industries continue to evolve, the demand for advanced filtration solutions like metal filter elements will only increase. Understanding the capabilities and advantages of these filter systems can help businesses enhance their operational efficiency while maintaining the highest standards of product quality and safety. With ongoing advancements in manufacturing technologies, the future of metal filtration looks promising, paving the way for innovative applications and enhanced performance across various sectors.

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

-

Air filter survival guide in high-dust environmentsNewsApr.23,2025

-

How do air filters cope with high-concentration dust environments?NewsApr.21,2025

Email:

Email: