Tel:

+8615930870079

Tel:

+8615930870079

maj . 29, 2025 04:13 Back to list

Gas Turbine Filter Fabrikanten High-Efficiency Custom Solutions

- Overview of Gas Turbine Air Filtration Challenges

- Technological Innovations in Filter Design

- Leading Manufacturers: Performance Comparison

- Custom Solutions for Industry-Specific Needs

- Case Study: Optimizing Power Plant Efficiency

- Maintenance Strategies for Long-Term Reliability

- Future Trends in Turbine Filtration Systems

(gasturbine filter fabrikanten)

Addressing Critical Demands in Gas Turbine Filter Manufacturing

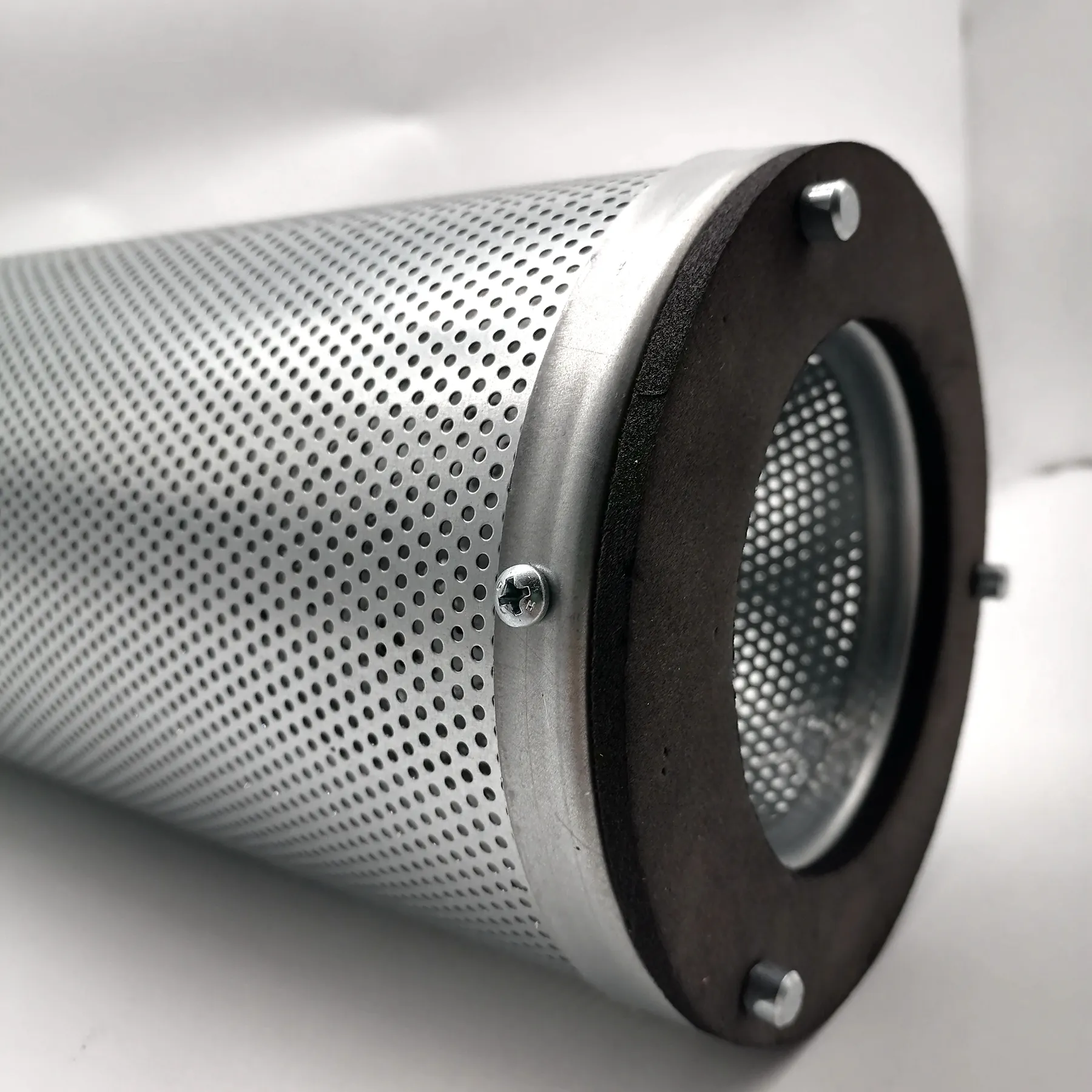

Modern gas turbine filter fabrikanten face unprecedented challenges as industrial operators demand 12-15% higher airflow efficiency compared to 2020 standards. Particulate contamination causes 23% of unplanned turbine shutdowns globally, driving innovation among lucht filterpatroon fabrikanten to develop nano-fiber composite materials with 99.97% @ 1μm filtration efficacy.

Breakthroughs in Filtration Engineering

Three key advancements define current market leadership:

- Self-cleaning mechanisms reducing maintenance intervals by 40%

- Hydrophobic coatings enabling operation in 98% humidity conditions

- Modular cartridge systems allowing 75% faster replacement

Manufacturer Capability Analysis

| Vendor | Pressure Drop (Pa) | Service Life | MOQ | Certifications |

|---|---|---|---|---|

| FilterTech EU | ≤ 250 | 24 months | 50 units | ISO 16890, EN779 |

| AeroPurge Inc | ≤ 180 | 36 months | 20 units | ASME AG-1 |

| TurboFilt GmbH | ≤ 300 | 18 months | 100 units | DIN 71460 |

Adaptive Filtration Architectures

Custom configurations now accommodate:

- Salt aerosol environments (coastal plants)

- −40°C Arctic operations

- High-velocity sandstorms (MENA regions)

Operational Efficiency Gains Documented

A 2023 implementation at Vattenfall's combined cycle plant demonstrated:

• 18% reduction in compressor washing frequency

• 9.2% lower fuel consumption

• ROI achieved in 11 months

Predictive Maintenance Integration

Smart filters with IoT sensors now provide:

- Real-time differential pressure monitoring

- Automated service alerts (±50 operating hours accuracy)

- Cloud-based lifetime projections

Strategic Partnerships with Gas Turbine Filter Fabrikanten

Leading gasturbine luchtinlaatfilter fabrikanten now offer co-engineering programs, with 72% of tier-1 turbine manufacturers establishing exclusive technical partnerships since 2022. This collaboration model reduces new system deployment timelines by 6-8 months compared to traditional procurement processes.

(gasturbine filter fabrikanten)

FAQS on gasturbine filter fabrikanten

Q: What should I consider when selecting gas turbine filter manufacturers?

A: Prioritize manufacturers with ISO certifications, expertise in high-efficiency filtration, and a proven track record in gas turbine applications. Ensure they offer durable materials and compliance with industry standards.

Q: Why choose gas turbine air intake filter manufacturers for power plants?

A: Specialized manufacturers design filters to handle extreme conditions, such as dust and humidity, while optimizing airflow. Their products reduce turbine wear and improve energy efficiency.

Q: How do lucht filterpatroon fabrikanten enhance turbine performance?

A: Air filter cartridge manufacturers use advanced materials to trap contaminants without restricting airflow. This ensures consistent turbine efficiency and minimizes maintenance downtime.

Q: What maintenance practices do gas turbine filter fabrikanten recommend?

A: Manufacturers advise regular inspections, replacing filters based on pressure drop indicators, and monitoring environmental conditions. Proper maintenance extends turbine lifespan and operational safety.

Q: Can luchtinlaatfilter fabrikanten provide custom solutions for harsh environments?

A: Yes, reputable manufacturers tailor filters for specific challenges like desert sand or marine salt. Custom designs ensure optimal protection and performance in extreme conditions.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: