Tel:

+8615930870079

Tel:

+8615930870079

paź . 13, 2024 11:58 Back to list

High-Efficiency Cartridge Filter for Enhanced Dust Extraction Performance

The Importance of Fine Cartridge Filters for Dust Extractors

In industrial settings, maintaining air quality and ensuring a safe working environment is paramount. Dust extractors play a crucial role in this regard, and one of their most vital components is the fine cartridge filter. These filters are designed to capture very fine particles from the air, preventing them from being released back into the environment. This article will delve into the significance of fine cartridge filters for dust extractors, discussing their functionality, benefits, selection criteria, and maintenance practices.

Functionality of Fine Cartridge Filters

Fine cartridge filters operate on the principle of mechanical filtration. They consist of a cylindrical design with a pleated structure that significantly increases the filtering surface area. This design allows for higher dust loading capacity and improved airflow efficiency. When the air laden with dust enters the filter, the particles collide with the filter media, which causes them to either be trapped on the surface or penetrate the filter material. As the filter captures more dust, it continues to maintain optimal air quality while reducing the workload on the dust extractor system.

The efficiency of fine cartridge filters is typically denoted by a percentage, indicating the size of particles they can capture. High-efficiency filters can trap particles as small as 1 micron, which is essential for industries dealing with fine dust, such as pharmaceuticals, food processing, and woodworking. The ability to filter out fine particulate matter not only protects equipment but also promotes a healthier workplace.

Benefits of Using Fine Cartridge Filters

1. Enhanced Air Quality The primary purpose of dust extractors equipped with fine cartridge filters is to improve air quality. By capturing fine dust particles, these filters help prevent respiratory issues among workers and maintain compliance with health regulations.

2. Increased Equipment Lifespan When fine dust particles are allowed to accumulate on machinery, they can cause wear and tear, leading to expensive repairs and replacements. Fine cartridge filters minimize this risk, prolonging the life of equipment and reducing maintenance costs.

3. Efficiency and Cost-Effectiveness While investing in high-quality fine cartridge filters might seem costly initially, their ability to reduce downtime and maintenance expenses makes them a wise choice in the long run. Moreover, efficient filters ensure that dust extractors operate at peak performance, translating to lower energy consumption.

4. Versatility Fine cartridge filters are available in various materials and configurations, making them suitable for different applications and industries. Whether dealing with granular materials or toxic particles, there is a filter designed to meet specific requirements.

Selecting the Right Fine Cartridge Filter

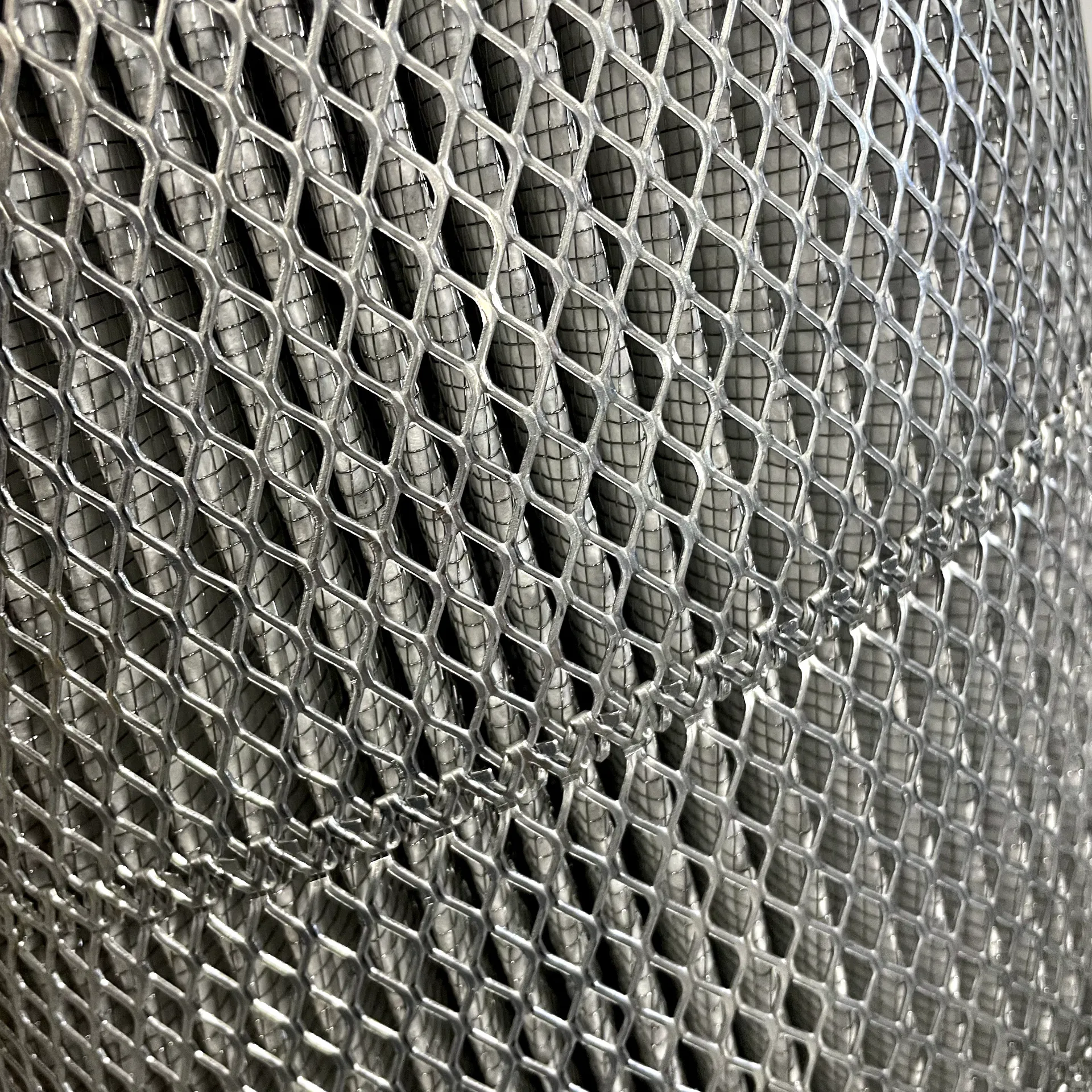

fine cartridge filter for dust extractor

When selecting a fine cartridge filter for a dust extractor, several factors must be considered

- Particle Size and Type Understanding the nature of the dust generated in a particular industry is crucial. Knowing the size distribution and chemical composition will guide you in choosing a filter with the appropriate efficiency and material compatibility.

- Airflow Requirements Different applications have different airflow needs. It's important to select a filter that fits seamlessly into the dust extraction system without impeding airflow.

- Filter Material The filter media can significantly affect performance. Common materials include polyester, PTFE, and cellulose. Each has its advantages and is suited to specific types of dust.

- Maintenance Needs Some filters require more maintenance than others. Choosing a filter that offers ease of cleaning or replacement can save valuable time and resources.

Maintenance Practices for Fine Cartridge Filters

To ensure optimal performance, regular maintenance of fine cartridge filters is essential. Here are a few best practices

- Regular Inspections Regularly checking filters for signs of wear, tears, or clogging will help identify issues before they escalate.

- Cleaning Depending on the filter type, periodic cleaning can extend its life. Many filters can be cleaned using compressed air or pulse-jet systems.

- Timely Replacement Even with proper maintenance, filters will eventually need replacement. Establishing a regular replacement schedule based on usage and environment ensures continuous performance.

In conclusion, fine cartridge filters are essential components of dust extractors that significantly enhance air quality and safety in industrial environments. Their ability to capture fine particles not only protects workers but also boosts equipment lifespan and operational efficiency. Selecting the right filter and adhering to proper maintenance protocols will maximize your dust extraction system’s performance, making it a crucial investment for any industry that generates airborne dust.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: