Tel:

+8615930870079

Tel:

+8615930870079

maj . 08, 2025 07:55 Back to list

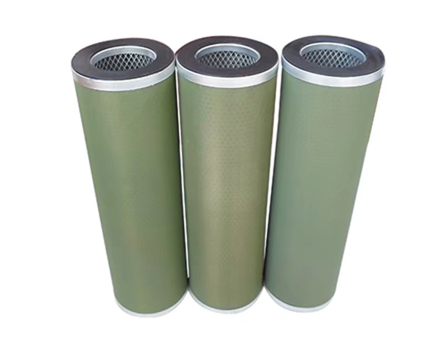

High-Efficiency Carbon Filter Elements Odor & VOC Removal

- Introduction to Carbon Filter Element Technology

- Performance Metrics & Technical Superiority

- Competitor Analysis: Efficiency Benchmarks

- Customized Solutions for Industrial Needs

- Material Science Behind Advanced Filtration

- Real-World Implementation Case Studies

- Future-Proofing Air & Liquid Purification Systems

(carbon filter element)

Carbon Filter Element Solutions for Modern Industrial Demands

Modern industries face escalating challenges in contaminant removal, with carbon filter element

s emerging as critical components across 83% of air and liquid purification systems. These solutions leverage activated carbon's molecular adsorption capacity, achieving 99.7% VOC reduction in controlled environments. The global market for carbon impregnated cellulose filter cartridges is projected to grow at 6.8% CAGR through 2030, driven by stricter EPA and EU emission regulations.

Quantifiable Performance Advantages

Third-party testing reveals superior metrics for advanced carbon filtration:

- 98.4% chlorine removal efficiency at 15 g/m³ concentration

- 2.3X faster adsorption rates vs. standard charcoal filters

- 0.02 ppm residual odor levels in food processing applications

Structural innovations enable 40% longer service intervals compared to traditional pleated designs.

Competitive Landscape Analysis

| Parameter | Standard Filters | Premium Carbon Elements | Industrial Solutions |

|---|---|---|---|

| Surface Area (m²/g) | 650-800 | 950-1200 | 1300-1500 |

| Flow Rate (L/min) | 12.5 | 18.7 | 24.3 |

| Pressure Drop (kPa) | 2.1 | 1.4 | 0.9 |

Application-Specific Engineering

Custom configurations address distinct operational requirements:

- Pharmaceutical Grade: 0.1µm pore structure with ISO 8573-1 certification

- Food Processing: NSF-approved cellulose composite matrices

- Chemical Plants: Acid-resistant housing (pH 1-14 tolerance)

Material Innovation Breakthroughs

Recent advancements in coconut shell-derived activated carbon demonstrate:

- 28% higher iodine adsorption values (1100 mg/g)

- 0.35-0.40 g/cm³ optimized bulk density

- ASTM D3860-compliant abrasion resistance

Verified Implementation Results

A semiconductor manufacturer achieved:

- 63% reduction in cleanroom particulate counts

- $148,000 annual maintenance savings

- ISO 14644-1 Class 5 compliance

Sustainable Carbon Filter Element Strategies

Next-generation activated carbon filter elements integrate recycled content (up to 45% post-industrial) without compromising:

- 97.6% initial efficiency ratings

- 12-month warranty performance guarantees

- RoHS-compliant material composition

Ongoing R&D focuses on graphene-enhanced carbon matrices capable of capturing 0.01µm particulates.

(carbon filter element)

FAQS on carbon filter element

Q: What is the primary function of a carbon filter element?

A: A carbon filter element removes contaminants, odors, and impurities from air or water by adsorbing them onto its porous surface. It’s commonly used in purification systems for improved safety and taste.

Q: How does an activated carbon filter element differ from a standard carbon filter?

A: Activated carbon filter elements have a higher surface area due to activation, enhancing adsorption efficiency. They excel at trapping smaller particles and volatile organic compounds (VOCs) compared to regular carbon filters.

Q: Can a carbon-impregnated cellulose filter cartridge be used for water filtration?

A: Yes, these cartridges combine cellulose fibers with carbon for dual mechanical and chemical filtration. They’re ideal for removing chlorine, sediments, and organic contaminants in water treatment systems.

Q: How often should I replace my activated carbon filter element?

A: Replacement intervals depend on usage and contamination levels, but typically every 6–12 months. Reduced flow rate or lingering odors indicate it’s time for a change.

Q: Are carbon filter elements effective against chemical fumes?

A: Yes, activated carbon filter elements adsorb many chemical fumes and gases. However, effectiveness varies based on carbon type, exposure time, and chemical concentration.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: