Tel:

+8615930870079

Tel:

+8615930870079

aug . 02, 2024 14:41 Back to list

Understanding the Importance of Dust Cartridges for Efficient Air Filtration Systems

Understanding Dust Percentage in Cartridge Filters

In various industrial applications, maintaining clean air is of paramount importance. One of the pivotal components in achieving this is the cartridge filter, specifically designed to trap dust and particulates from air or liquids. An essential metric to consider when evaluating the efficiency of these filters is the dust percentage or dust load. This article will delve into what dust percentage means, its significance, and its implications for businesses relying on cartridge filters.

What is Dust Percentage?

Dust percentage refers to the quantity of dust collected by a filter cartridge relative to the total volume of air or fluid passed through it. This metric plays a crucial role in determining filter performance and suggests how effective a filter is at capturing airborne particles. Typically expressed as a percentage, a higher dust percentage indicates a more efficient filter, as it can capture a greater proportion of contaminants.

The Importance of Monitoring Dust Percentage

1. Operational Efficiency One of the primary reasons for tracking dust percentage is to ensure optimal performance of filtration systems. When filters capture a high percentage of dust, it signifies they are effectively doing their job. Conversely, a low dust percentage may point towards a malfunction or that the filter needs replacement.

2. Cost-Effectiveness Filters that are able to maintain a high dust load can result in lower operational costs. By minimizing air pollution and ensuring cleaner processes, businesses can reduce expenses associated with equipment maintenance and energy consumption.

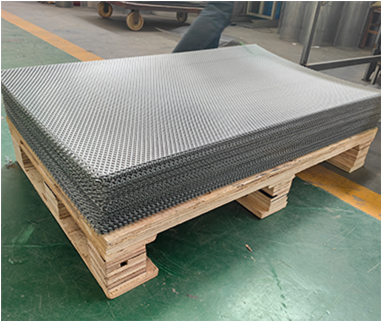

dust cartridge

3. Compliance and Environmental Impact Many industries are subject to stringent regulations regarding air quality. A high dust percentage can help companies remain compliant with environmental standards by ensuring a cleaner emission into the atmosphere. This is crucial not only for legal compliance but also for upholding a company’s reputation and commitment to sustainability.

4. Health Considerations In industries such as pharmaceuticals, food, and electronics, controlling dust is vital to ensure the health and safety of employees as well as the integrity of products. By monitoring dust percentage, businesses can mitigate health risks associated with inhaling harmful particulates.

Challenges in Measuring Dust Percentage

Accurately measuring the dust percentage in cartridge filters can be challenging. Factors such as airflow rate, particle size, and filter saturation all influence the data collected. Additionally, careful calibration of measurement instruments is required to obtain reliable results. Many businesses employ advanced technologies, such as particle counters and real-time monitoring systems, to ensure precise measurement and analysis.

Conclusion

In conclusion, understanding dust percentage is essential for any industry that relies on cartridge filters for air or liquid purification. Monitoring this metric allows organizations to enhance operational efficiency, reduce costs, comply with regulations, and safeguard health and safety standards. As the importance of clean air and efficient filtration systems continues to grow, businesses must strive for high dust percentages in their filtration processes. Not only does this contribute to improved product quality and environmental sustainability, but it also fosters a healthier workplace for employees. By investing in quality cartridge filters and effectively measuring their dust percentage, companies can achieve lasting benefits and ensure their operations run smoothly.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: