Tel:

+8615930870079

Tel:

+8615930870079

nov . 09, 2024 05:19 Back to list

High-Performance Stainless Steel Filter Elements for Efficient Filtration Solutions

The Importance of Stainless Steel Filter Elements in Modern Filtration Systems

In the vast domain of industrial processes and applications, the quality and efficiency of filtration systems play a crucial role. Among the various materials utilized for filter elements, stainless steel has emerged as a leading choice. Its unique properties make it particularly well-suited for a wide range of filtering applications, from water treatment to petrochemical processing. In this article, we will discuss the importance of stainless steel filter elements, exploring their benefits, applications, and impact on different industries.

Properties of Stainless Steel

Stainless steel is an alloy of iron that contains a minimum of 10.5% chromium, which enhances its resistance to corrosion and oxidation. This characteristic is vital for filter elements that operate in harsh environments or are exposed to aggressive media. Additionally, stainless steel maintains its strength and structural integrity at high temperatures, making it an excellent choice for high-temperature applications.

The material's durability and longevity ensure that stainless steel filter elements can withstand the rigors of continuous use, reducing the frequency of replacement and maintenance. This reliability ultimately leads to cost savings for businesses while ensuring that filtration systems operate efficiently.

Advantages of Stainless Steel Filter Elements

1. Corrosion Resistance One of the standout features of stainless steel is its resistance to corrosion. This property makes stainless steel filter elements ideal for applications involving water, chemicals, and other corrosive substances. By preventing degradation, stainless steel filters maintain their performance over time.

2. High Strength Stainless steel filter elements are robust and can endure high pressures without compromising their structural integrity. This strength is particularly important in industrial settings where filtration systems must handle significant fluid volumes and pressures.

3. Reusable and Eco-friendly Unlike disposable filters made from paper or synthetic materials, stainless steel filters can be cleaned, reused, and recycled. This not only reduces waste but also aligns with global sustainability initiatives aimed at minimizing environmental impact.

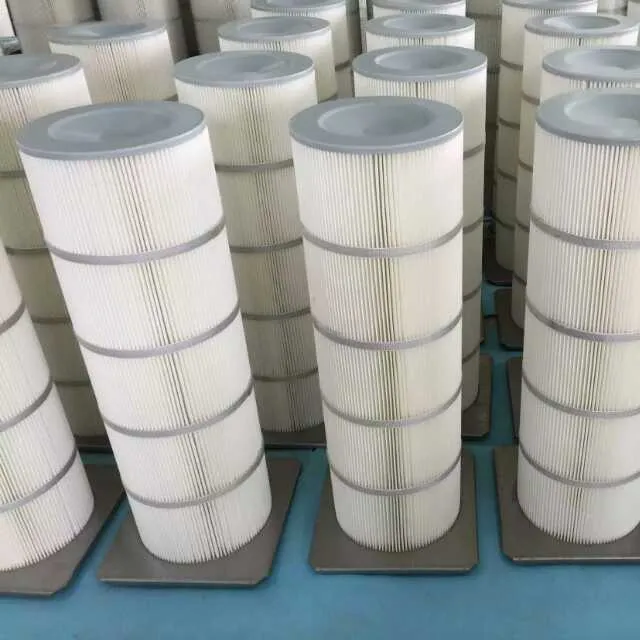

4. Versatility Stainless steel filter elements come in various designs, including cylindrical, pleated, and disk shapes, allowing them to be customized for specific applications. They can also be designed to meet diverse filtration requirements, from coarse to fine filtration.

5. Temperature Resistance These filters can perform effectively in extreme temperature conditions, maintaining their structural integrity and filtration efficiency. This characteristic makes them suitable for applications such as oil and gas, chemical processing, and food and beverage industries.

stainless steel filter element

Applications of Stainless Steel Filter Elements

Stainless steel filter elements find applications in numerous industries, including

- Water Treatment In water filtration systems, stainless steel filters help remove impurities, sediments, and microorganisms. Their corrosion resistance allows for effective use in both municipal and industrial water treatment plants.

- Chemical Industry The chemical industry often deals with aggressive substances that can corrode other materials. Stainless steel filter elements ensure safe and reliable operation, minimizing contamination risks.

- Food and Beverage In the food and beverage sector, maintaining product purity is paramount. Stainless steel filters provide a hygienic solution for filtering liquids like juices, oils, and brewing processes while meeting stringent health regulations.

- Pharmaceuticals The pharmaceutical industry requires filters that can ensure the purity of products. Stainless steel filter elements not only filter out contaminants but also withstand the rigorous cleaning processes required in this sector.

- Oil and Gas In oil and gas applications, stainless steel filters are essential for separating particulates from crude oil and natural gas, ensuring the efficiency and safety of operations in the field.

Conclusion

Stainless steel filter elements have become a staple in modern filtration systems due to their unique properties, such as corrosion resistance, durability, and versatility. Their ability to perform reliably across various industries makes them an invaluable asset for businesses seeking efficient filtration solutions. As the demand for high-quality filtration grows, the importance of stainless steel filter elements will only continue to rise, paving the way for innovative advancements in the field of filtration technology.

In summary, the adoption of stainless steel filter elements not only enhances the efficiency and effectiveness of filtration processes but also contributes to sustainability efforts in industrial applications. It is clear that stainless steel will remain a leading material in the evolution of filtration technology for years to come.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: