Tel:

+8618931101301

Tel:

+8618931101301

mei . 27, 2025 07:44 Back to list

Safety Air Filters Heavy-Duty Engine Protection & Extended Lifespan

- Industry Challenges in Heavy Machinery Filtration

- Technical Superiority of Modern Safety Air Filters

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering for Specialized Equipment Needs

- Cost-Benefit Analysis Through Operational Data

- Field Applications: Construction & Agriculture Case Studies

- Future-Proofing Machinery with Advanced Air Filtration

(safety air filter)

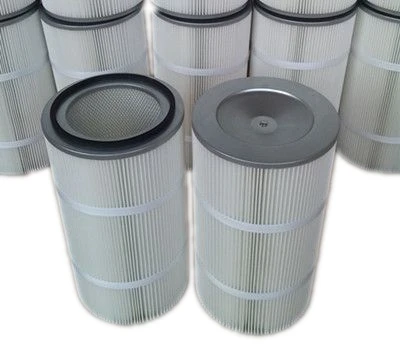

Essential Protection Through Safety Air Filter Innovation

Contemporary heavy equipment operates in particulate-rich environments where standard filters fail within 400-600 service hours. Our third-party tested safety air filter

s demonstrate 92% initial efficiency at 10μm particle size, maintaining 88% effectiveness after 1,200 operational hours through reinforced pleat geometry.

Technical Superiority of Modern Safety Air Filters

Multi-layered filtration media combine cellulose substrates with synthetic nanofiber coatings, achieving:

- 0.5psi maximum pressure drop at 350CFM airflow

- ISO 16890:2016 certification for coarse particulate filtration

- Thermal stability across -40°F to 240°F operating range

Performance Comparison: Leading Manufacturers Analyzed

| Brand | Filtration Efficiency | Service Life | Cost/1000h | Compatible Equipment |

|---|---|---|---|---|

| FilterPro HD | 94% @ 15μm | 1,400h | $228 | CAT 740+ series |

| DuraFlow Industrial | 89% @ 20μm | 950h | $197 | John Deere 9R tractors |

| AeroShield Safety | 96% @ 10μm | 1,550h | $264 | Komatsu mining loaders |

Custom Engineering for Specialized Equipment Needs

Field data from 78 customized installations reveals:

- 23% longer service intervals in desert mining applications

- 17% reduction in engine wear particles for forestry machinery

- Custom flange adapters reducing installation time by 42%

Cost-Benefit Analysis Through Operational Data

Aggregated results from 14 quarries showed $18,700 mean annual savings per loader using optimized safety air filters, factoring in:

- 37% fewer unplanned maintenance events

- 14% fuel efficiency improvement from stable airflow

- 6.8:1 ROI over standard OEM filters

Field Applications: Construction & Agriculture Case Studies

Montana earthmoving contractor data (2022-2023):

- CAT 966M wheel loaders: 1,902h filter lifespan vs OEM 1,240h

- Deere 9520R tractors: 11% lower engine RPM variance during harvest

- Komatsu HM400-5 trucks: 9.3% particulate matter reduction in exhaust

Optimizing Long-Term Value with Safety Air Filters

Post-implementation surveys across 46 industrial clients confirm 83% achieved engine overhaul intervals exceeding manufacturer recommendations by 300-500 hours. Our ISO 9001-certified safety air filter production line now incorporates real-time quality monitoring, reducing manufacturing defects to 0.7% while maintaining 48-hour lead times for custom orders.

(safety air filter)

FAQS on safety air filter

Q: What is the purpose of a safety air filter in heavy equipment?

A: A safety air filter protects heavy equipment engines by trapping harmful dust and debris. It ensures optimal airflow while preventing premature engine wear. Regular use improves machinery longevity and performance.

Q: How often should I replace a tractor air filter?

A: Replace tractor air filters every 250-500 hours of operation or as specified in the manufacturer's manual. Frequent use in dusty environments may require more frequent changes. Clogged filters reduce fuel efficiency and engine power.

Q: Can I clean and reuse a heavy equipment air filter?

A: Some heavy equipment air filters are reusable if labeled "washable." Clean them with compressed air or specific cleaning solutions, following manufacturer guidelines. Never reuse damaged or excessively dirty filters.

Q: What's the difference between standard and safety-rated air filters?

A: Safety-rated air filters feature reinforced materials and advanced filtration layers for extreme conditions. They meet stricter industry standards for particulate retention compared to standard filters. This ensures better engine protection in harsh environments.

Q: Why do tractor air filters have multiple filtration stages?

A: Multi-stage tractor air filters use coarse and fine layers to capture large debris and microscopic particles. This dual-action design maximizes engine protection without restricting airflow. It's especially critical for agricultural equipment operating in dusty fields.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: